Instructions for High Altitude Conversion

6

We reserve the right to make any changes due to technical modifications!

Instructions for high altitude conversion for sealed combustion gas boiler GA124 • Issue

03/2005

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

for leaks by applying a soap and water solution. If

no leaks are found, go to step 25. If any leaks are

found, shut off the main gas shut off valve.

24.

Repair leaks and repeat step 23.

25.

Shut off the main gas supply shut-off valve. Remove

the line pressure tapping plug (Fig. 7,

Item. 2

) from

the gas control. Install a test fitting, and hook up a

manometer to measure the supply pressure.

26.

Remove the manifold pressure tapping plug (Fig. 7,

Item. 3

) from the gas control. Install a test fitting and

hook up a manometer to measure the manifold

pressure.

27.

Open the main gas piping shut off valve and

measure the supply pressure to the boiler. The

supply pressure must be between 4.7 and 10.5

inches of water column for natural gas or 11 and 13

inches water column for propane. If the pressure is

not between 4.7 and 10.5 inches water column for

natural gas (or 11 and 13 inches of water column for

propane), when the boiler is running, call your

service technician or gas supplier.

28.

Follow the lighting instructions on the next page.

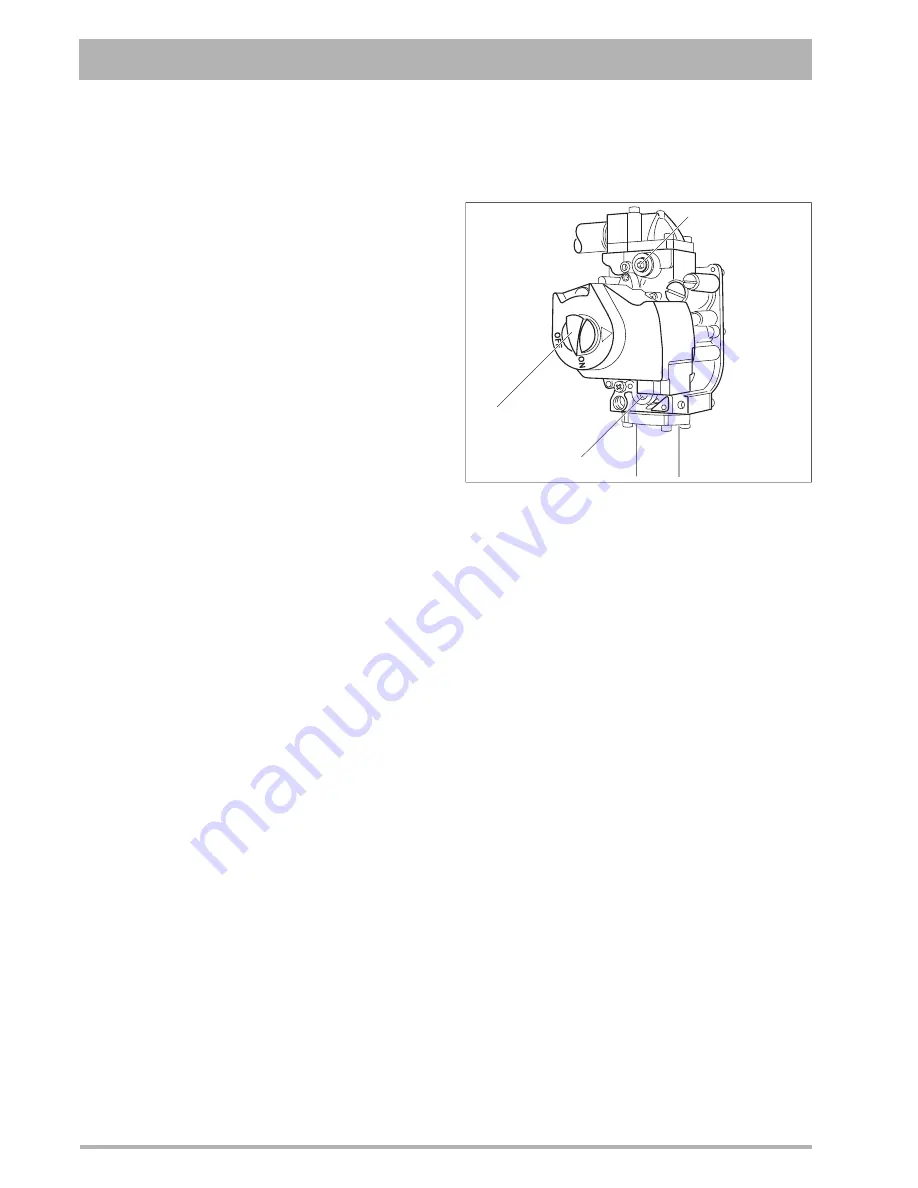

Fig. 7

Gas control valve

Item. 1:

gas control knob (set to position „ON“)

Item. 2:

supply pressure test port

Item. 3:

manifold pressure test port

3

2

1

Summary of Contents for Logano GA124-17

Page 5: ......