20

INSTALL CLAMPS ON DRAIN TUBE

ATTACH DRAIN TUBE TO CONDENSATE

DRAIN TRAP

PULL DRAIN STUB

THROUGH CASING

OPEN SPRING CLAMP

INSERT FACTORY

ï

SUPPLIED 1/2

ï

IN. CPVC

TO 3/4

ï

IN. PVC ADAPTER OR 1/2

ï

IN. CPVC PIPE

*CLAMP MAY BE LOCATED ON OUTSIDE OF DRAIN

TUBE

A11342A

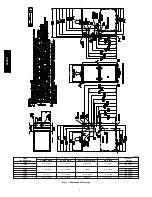

Fig. 15 -- Formed Rubber Drain Grommet

A11581

Fig. 16 -- Modify Rubber Drain Elbow

Remove knockout.

Install grommet before

relocating condensate

trap.

NOTE: Trap grommet is required only for direct-vent

applications.

A11582

Fig. 17 -- Horizontal Drain Trap Grommet

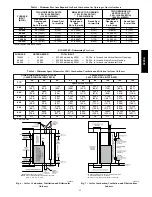

ATTACH ELBOW TO

CONDENSATE TRAP

CUT FORMED END OFF

CONDENSATE DRAIN

ELBOW

CONNECT SHORT END OF

’Z’ PIPE TO MODIFIED

DRAIN ELBOW

FORMED END OF GROMMET. OPEN

SPRING CLAMP, INSERT 1/2

ï

IN. TO 3/4

ï

IN.

CPVC TO PVC ADAPTER OR CPVC PIPE

FORMED END

OF GROMMET

FACTORY SUPPLIED

1/2

ï

IN. CPVC TO 3/4

ï

IN.

PVC ADAPTER

NOTE: Remove Inducer Housing for easier access, if desired.

MODIFIED DRAIN ELBOW CON-

NECT TO CONDENSATE TRAP

AND ’Z’ PIPE

TOP VIEW

DRAIN ELBOW “Z” DISCHARGE PIPE FOR LEFT SIDE

DRAIN IS ROUTED BEHIND INDUCER

FRONT VIEW

LEFT SIDE DRAIN PIPE ORIENTATION FOR CONDENSATE DISCHARGE

A170128

Fig. 18 -- Drain Trap Connection and Routing

(Appearance may vary)

INSTALLATION

This furnace is certified to leak 2% or less of nominal air

conditioning CFM delivered when pressurized to 1--in. water

column with all present air inlets, including bottom closure in

upflow and horizontal applications, air outlets, and plumbing

and electrical ports sealed.

NOTICE

Upflow Installation

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in nuisance limit

switch cycling and unit component damage.

When a 17--1/2--in. wide upflow N coil is used with a

42060 furnace, the N coil must either be raised using a

transition piece at least 3--in. (76 mm) high or if a transition

piece is not used, the refrigerant lines must point to the front

of the furnace casing.

CAUTION

!

N Coil Installation

When a 17--1/2--in. wide upflow N coil is used with a 42060

furnace, the N coil must either be raised using a transition piece at

least 3--in. (76 mm) high or if a transition piece is not used, the

refrigerant lines of the N coil must point to the front of the furnace

casing.

Factory accessory 4--3/4--in. transitions are available.

Refer to the Product Data sheet for the current accessory transition

part number.

NOTE:

The furnace must be pitched as shown in Fig. 25 for

proper condensate drainage.

922SA