15

9. Pull the grommet through the casing from the outside until

it is seated in the knockout.

10. Align the Z-pipe with the long end of the grommet inside

the furnace and insert slightly. The angled end of the tube at

the other side of the casing should be facing the front of the

furnace.

11. Slide a spring clamp over the end of the remaining rubber

drain elbow.

12. Attach the drain elbow to the angled end of Z-pipe and the

drain trap outlet stub. Adjust the length of Z-pipe inserted

into the grommet at the opposite side of the furnace as

necessary for proper fit and positioning. In both upflow and

downflow orientations, the Z-pipe should NOT be resting

on any sheet metal parts.

13. Secure the rubber elbow to the drain trap and the Z-pipe

with spring clamps.

14. Secure the grommet to the Z-pipe with the spring clamp.

The remaining drain line can be constructed from field supplied

1/2--in. CPVC or 3/4--in. PVC pipe, in compliance with local

building codes. A factory-supplied 1/2--in. CPVC to 3/4--in. PVC

adapter is supplied in the loose parts bag for use as required.

15. Install the adapter or connect the 1/2--in. CPVC pipe by

sliding a spring clamp over the open end of the grommet on

the outside the furnace casing.

16. Open the spring clamp and insert the long end of the

adapter or the 1/2--in. CPVC pipe into the outlet stub on the

drain tube.

17. Connect additional condensate piping to a code-approved

drain, or to a condensate pump approved for use with acidic

furnace condensate and compatible with mineral and

vegetable oils, such as canola oil.

Allow at least 1/4-in. per foot (20 mm per meter) of slope down

and away from the furnace in horizontal sections of drain line.

The field--supplied, accessory horizontal drain trap grommet is

ONLY REQUIRED FOR DIRECT VENT APPLICATIONS.

It is NOT required for applications using single--pipe or

ventilated combustion air venting.

NOTICE

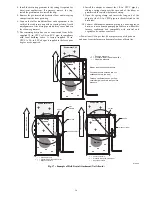

TIP FROM CONTRACTORS

: When installing the furnace

horizontally, use the entire drain elbow (that is, do NOT cut as

shown in Fig. 14 to connect the trap to the drain line. This helps to

prevent bumps and shocks to the drain line from damaging the

furnace drain trap. Avoid misalignment of the drain pipe which

may cause kinks in the elbow.

A11581

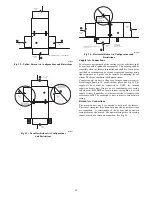

Fig. 14 -- Modify Rubber Drain Elbow

INSTALL CLAMPS ON DRAIN TUBE

ATTACH DRAIN TUBE TO CONDENSATE

DRAIN TRAP

PULL DRAIN STUB

THROUGH CASING

OPEN SPRING CLAMP

INSERT FACTORY

ï

SUPPLIED 1/2

ï

IN. CPVC

TO 3/4

ï

IN. PVC ADAPTER OR 1/2

ï

IN. CPVC PIPE

*CLAMP MAY BE LOCATED ON OUTSIDE OF DRAIN

TUBE

A11342A

Fig. 15 -- Formed Rubber Drain Grommet

ATTACH ELBOW TO

CONDENSATE TRAP

CUT FORMED END OFF

CONDENSATE DRAIN

ELBOW

CONNECT SHORT END OF

’Z’ PIPE TO MODIFIED

DRAIN ELBOW

FORMED END OF GROMMET. OPEN

SPRING CLAMP, INSERT 1/2

ï

IN. TO 3/4

ï

IN.

CPVC TO PVC ADAPTER OR CPVC PIPE

FORMED END

OF GROMMET

FACTORY SUPPLIED

1/2

ï

IN. CPVC TO 3/4

ï

IN.

PVC ADAPTER

NOTE: Remove Inducer Housing for easier access, if desired.

MODIFIED DRAIN ELBOW CON-

NECT TO CONDENSATE TRAP

AND ’Z’ PIPE

TOP VIEW

DRAIN ELBOW “Z” DISCHARGE PIPE FOR LEFT SIDE

DRAIN IS ROUTED BEHIND INDUCER

FRONT VIEW

LEFT SIDE DRAIN PIPE ORIENTATION FOR CONDENSATE DISCHARGE

A170128

Fig. 16 -- Drain Trap Connection and Routing

(Appearance may vary)

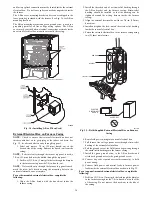

Horizontal Orientation

1. The condensate trap outlet extends 2--in. (51 mm) below the

furnace casing. Leave enough clearance between the furnace

and the furnace platform for the trap.

2. To allow for servicing the trap, the condensate drain elbow

in the loose parts bag can be used to make a coupler to

allow for future service of the condensate trap and drain

line.

3. Remove the knock-out for the condensate trap in the side of

the casing.