—7—

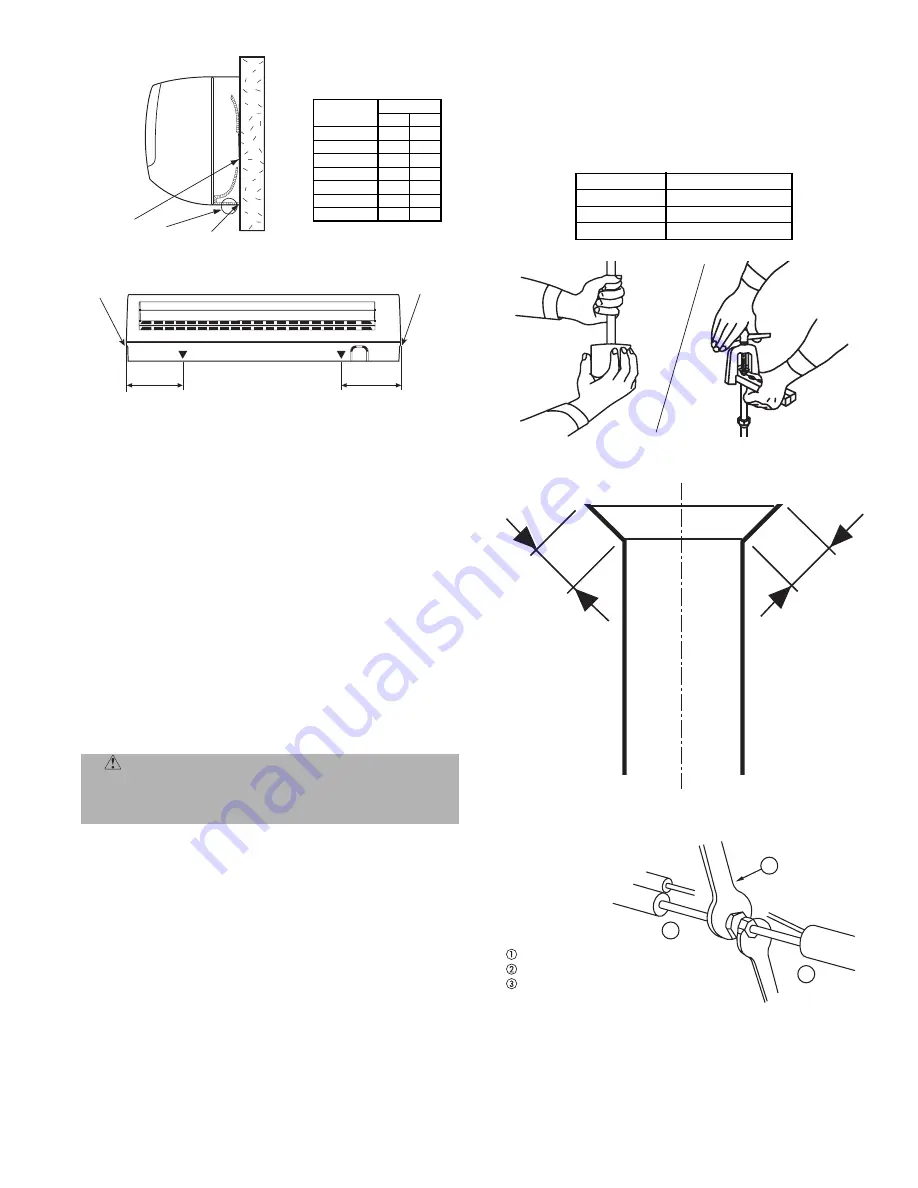

F. Make Piping Sweat Connections

Remove plastic caps from liquid and suction service valves.

Use refrigerant grade tubing.

Position tube end downward and cut the tube to the

requested length. Remove the burrs with a reamer. See

Fig. 12.

NOTE

: Oil in the compressor is extremely susceptible to

moisture absorption. Keep ends of tubing sealed during

installation.

Remove flare nuts from the unit connections and place them

on the tube end. Flare the tube with the flaring tool. The

flare end must not have any burrs or imperfections. The

length of the flared walls must be uniform. See Fig. 13.

Lubricate the tube end and thread of the flare fitting with

antifreeze oil. Tighten the fitting several turns, then tighten

it fully with two wrenches by applying the tightening torque

indicated in Table 4 and Fig. 14.

G. Air Purging And Leak Test

Only use a vacuum pump to purge air from the piping. Refer

to Fig. 15.

IMPORTANT:

Do not use the system compressor as a vacuum

pump.

IMPORTANT:

Do not use the unit refrigerant gas to purge

the connecting pipes.

Remove the caps from the valves.

Create a vacuum with a

vacuum pump connected to the service connection

of the suc-

tion shut-off valves completely shut until a 50 Pa vacuum

has been reached.

Open the mixed phase valve for 3 seconds, then quickly shut

it to check for possible leaks.

Replace caps and check for leaks using a leak detector spe-

cific for R-410A refrigerant.

After the leak test, fully open the three-way valves.

Table 4 — Tightening Torque

CAUTION:

Insufficient tightening torque will

cause gas leaks. Overtightening the fittings will dam-

age the tube flaring and cause gas leaks. Equipment

damage and personal injury may result.

VALVE SIZE

FLARE NUT (in.-lb)

3

/

8

in.

372

5

/

8

in.

487

3

/

4

in.

885

A

Wall

Hanging

Bracket

Hook

Hole

Retainer

Clip

Retainer

Clip

B

UNIT SIZE

DIMENSION

A

B

619ENF01824

13.4

10.6

619ENF030

12.2

12.2

619ENF036

12.2

12.2

619ENQ018

13.4

10.6

619ENQ024

13.4

10.6

619ENQ030

12.2

12.2

619ENQ036

12.2

12.2

Fig. 11 — Wall Hanging Details

Fig. 12 — Removing Burrs

L

L

Fig. 13 — Flared Walls are Equal

Fig. 14 — Tightening Connections

Adjustable wrench or torque wrench

Outdoor end

Indoor end

3

1

2

Summary of Contents for 619ENF

Page 9: ... 9 Fig 16 619ENF01824 Matched with 538ENF Typical Wiring Schematic ...

Page 10: ... 10 Fig 17 619ENQ018 024 Matched with 538QNF Typical Wiring Schematic ...

Page 11: ... 11 Fig 18 619ENF030 036 Matched with 538ENF Typical Wiring Schematic ...

Page 12: ... 12 Fig 19 619ENQ030 036 Matched with 538QNF Typical Wiring Schematic ...

Page 16: ...Copyright 2006 Bryant Heating Cooling Systems Printed in U S A CATALOG NO 02 619E0001 SI ...