X.

START-UP

CAUTION:

To prevent compressor damage or personal

injury, observe the following:

• Do not overcharge system with refrigerant.

• Do not operate unit in a vacuum or at negative pressure.

• Do not disable low-pressure switch.

In scroll compressor applications:

• Dome temperatures may be hot.

• In 3-phase application, incorrect phasing will cause

reverse rotation, resulting in elevated noise levels, equal-

ized pressures, and reduced current draw. Correct by

reversing power connection L1 and L2 on contactor.

CAUTION:

To prevent personal injury wear safety

glasses, protective clothing, and gloves when handling

refrigerant and observe the following:

• Back seating service valves are not equipped with

Schrader valves. Fully back seat (counter clockwise)

valve stem before removing gage port cap.

• Front seating service valves are equipped with Schrader

valves.

CAUTION:

Do not vent refrigerant to atmosphere. Re-

cover during system repair or final unit disposal.

1. The outdoor unit is equipped with a crankcase heater which

operates at temperatures less than 75°F. If outdoor tempera-

ture is less than 75°F, energize crankcase heater 24 hr

before starting unit. To energize heater only, set indoor

thermostat to OFF position and close power disconnect to

unit.

2. Fully back seat (open) liquid and vapor tube service valves.

3. Unit is shipped with valve stem(s) front seated and caps

installed. Replace stem caps after system is opened to

refrigerant flow (back seated). Replace caps finger tight and

tighten additional 1/12 turn (20 ft-lb torque) with wrench.

4. Close electrical disconnects to energize system.

5. Set room thermostat at desired temperature. Be sure set

point is below indoor ambient and is set low enough to

energize desired speed.

NOTE:

Bryant electronic thermostats are equipped with a 15-

minute staging timer. This timer prevents the 2-speed system from

operating at high speed until unit has been operating in low speed

for 15 minutes unless there is at least a 5°F difference between

room temperature and thermostat set point. To force high speed

(after a minimum of 2 minutes in low speed), adjust the set point

at least 5° below room ambient.

6. Set room thermostat to COOL and fan control to AUTO or

ON as desired. Wait for appropriate time delay(s) and

2-minute minimum low-speed run time. Operate unit for 15

minutes. Check refrigerant charge.

XI.

CHECK CHARGE

WARNING:

Service valve gage ports are not equipped

with Schrader valves. To prevent personal injury, make

sure gage manifold is connected to the valve gage ports

before moving valves off fully back seated position. Wear

safety glasses and gloves when handling refrigerant.

A.

Unit Charge

Factory charge is shown on unit rating plate.

NOTE:

When 2-speed unit is operating at low speed, system

vapor (suction) pressure will be higher than a standard single-

speed system or high-speed operation. This normal operation is

due to the reduced capacity operating with typically larger indoor

and outdoor coils.

Adjust charge by following procedure shown on charging tables

located on unit.

NOTE:

If superheat or subcooling charging conditions are not

favorable, charge must be weighed in accordance with unit rating

plate

±

0.6 oz/ft of 3/8-in. liquid line above or below 15 ft

respectively.

EXAMPLE:

25 ft - 15 ft = 10 ft X 0.6 oz/ft = 6 oz of additional charge

B.

Cooling Only Procedure

1. Operate unit a minimum of 10 minutes before checking

charge.

2. Measure liquid service valve pressure by attaching an

accurate gage to service port.

3. Measure liquid line temperature by attaching an accurate

thermistor type or electronic thermometer to liquid line near

outdoor coil.

4. Refer to unit rating plate for required subcooling tempera-

ture.

5. Refer to Table 6. Find the point where required subcooling

temperature intersects measured liquid service valve pres-

sure.

6. To obtain required subcooling temperature at a specific

liquid line pressure, add refrigerant if liquid line tempera-

ture is higher than indicated or reclaim refrigerant if

temperature is lower. Allow a tolerance of

±

3°F.

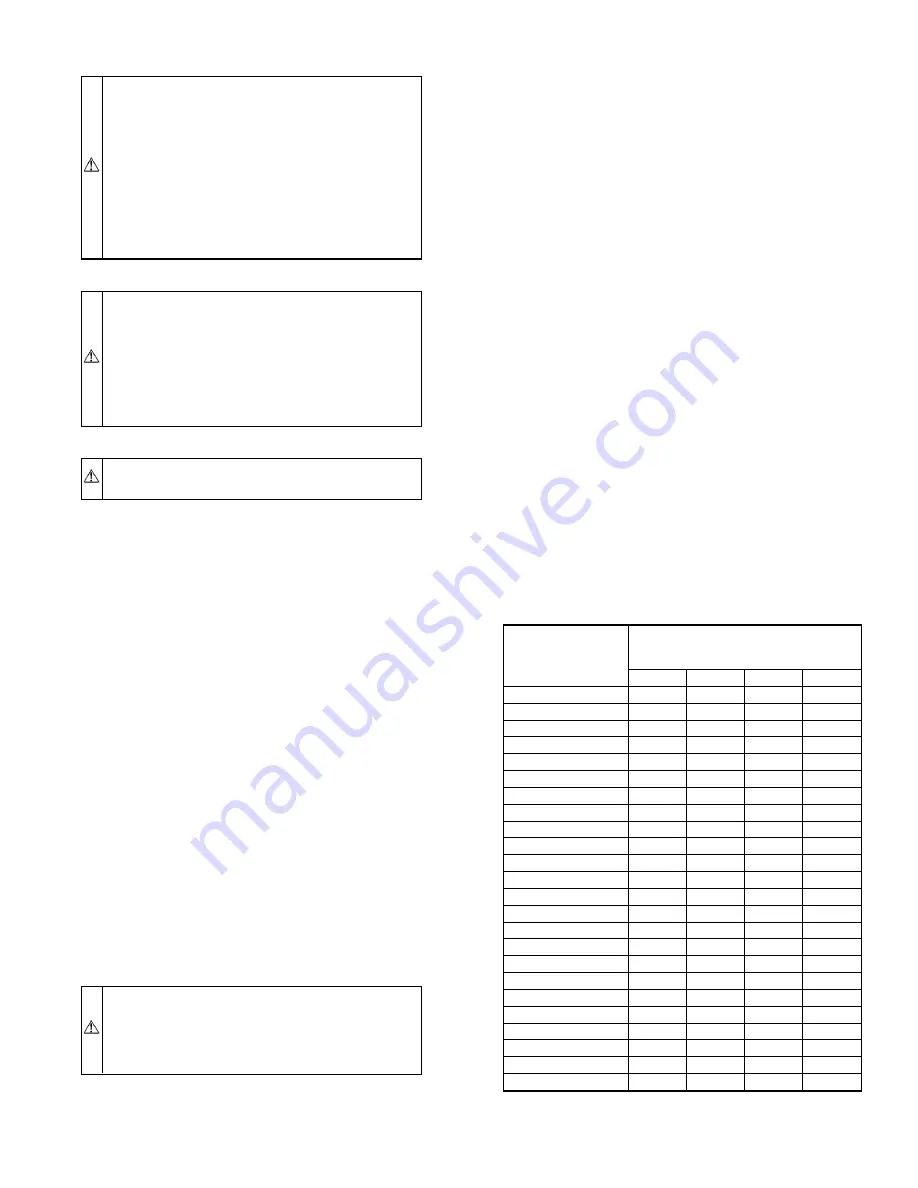

TABLE 6—REQUIRED LIQUID-LINE TEMPERATURE (°F)

LIQUID

PRESSURE AT

SERVICE VALVE

(PSIG)

REQUIRED SUBCOOLING

TEMPERATURE

(°F)

5

10

15

20

134

71

66

61

56

141

74

69

64

59

148

77

72

67

62

156

80

75

70

65

163

83

78

73

68

171

86

81

76

71

179

89

84

79

74

187

92

87

82

77

196

95

90

85

80

205

98

93

88

83

214

101

96

91

86

223

104

99

94

89

233

107

102

97

92

243

110

105

100

95

253

113

108

103

98

264

116

111

106

101

274

119

114

109

104

285

122

117

112

107

297

125

120

115

110

309

128

123

118

113

321

131

126

121

116

331

134

129

124

119

346

137

132

127

122

359

140

135

130

125

—13—