IntelliGear Plus

TM

Variable Speed Gearmotors and Motors

TX-10

TX-20

2 - Installation

It is the responsibility of the owner or user

to ensure that the installation, operation and maintenance

of the inverter and its options comply with legislation relating

to the safety of personnel, animals and equipment, and with

the current regulations of the country of use.

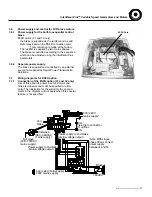

• Before carrying out any work, disconnect and lock the drive

power supply. For the single-phase range, wait two minutes

to make sure that the capacitors have discharged.

• After connection, ensure that the seals are firmly in place,

and that the screws and cable glands are watertight to ensure

drive protection. Clear any condensation from the drain holes

at the bottom of the motor.

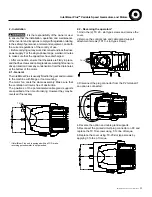

2.1 - General

The

I

ntelliGear Plus is usually fitted to the gear and mounted

to the machine with flange or foot mounting.

The motor fan cools the whole assembly. Make sure that

the ventilation air inlet is free of obstruction.

The positions of the potentiometer/cable gland supports

are specified at the time of ordering. However they may be

reversed if necessary.

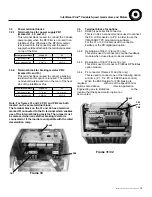

4. Reverse the option and cable gland supports.

5. Reconnect the printed circuit plug connector on P2 and

replace the TX 10 screws using .5 ft.-lbs. of torque.

6. Replace the cover using TX-20 slot type screws by

applying 3 ft.-lbs. of torque.

3. Disconnect the plug connector from the P2 terminal if

an option is connected.

2.2 - Reversing the operators*

1. Undo the (2) TX 20 - slot type screws and remove the

cover.

2. Remove the control knob and cable gland support

attachment screws (TX10 - slot type screws).

* If IntelliGear Plus unit is equipped with an FCR brake,

reversing potentiometer is not permitted.

MCIM15100E • Form 9112E • Printed in USA

11