S-7220C

8. STANDARD ADJUSTMENTS

39

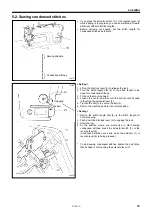

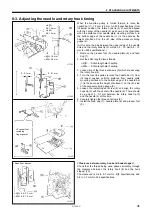

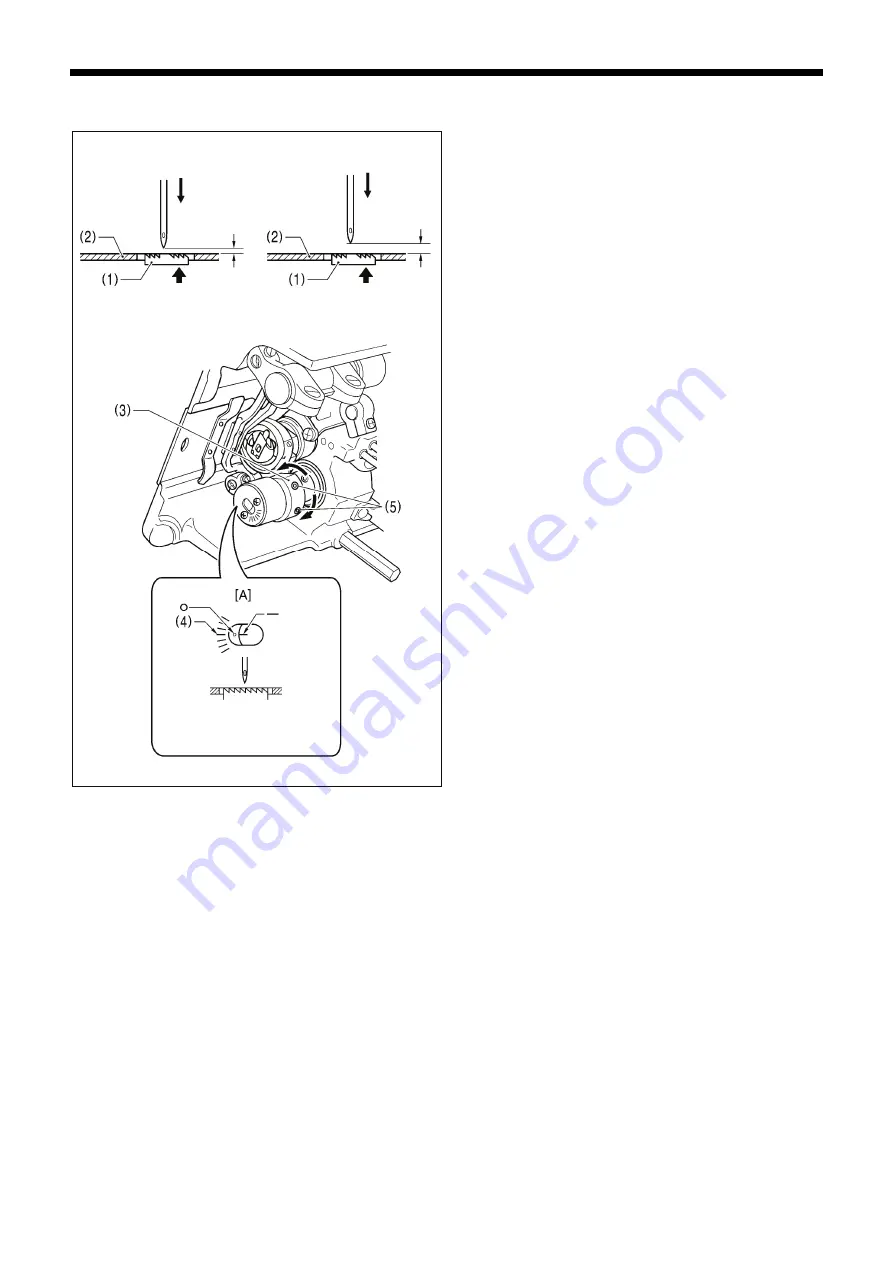

8-6. Adjusting the needle and feed mechanism timing

The standard timing is for the tip of the needle to be in the

position given below when the machine pulley is turned

forward to raise the feed dog (1) from its lowest position until

it is flush with the top of the needle plate (2).

(At this time, the “-” mark on the lower shaft will be aligned

with the center of the scale (4) (“O” mark) on the vertical cam

(3).)

<-4[]3>… There is a gap of approximately 2 mm between

the tip of the needle and the top of the needle

plate (2).

<-405>… There is a gap of approximately 4 mm between

the tip of the needle and the top of the needle

plate (2).

1. Set the stitch length dial to the maximum setting.

2. Tilt back the machine head.

3. Loosen the two set screws (5), and then turn the vertical

cam (3) sligtly to adjust the timing.

NOTE:

Use the standard needle and feed mechanism

timing.

If the timing is changed, broken needles may

occur.

4. After adjustment is completed, securely tighten the two

screws (5).

0578D

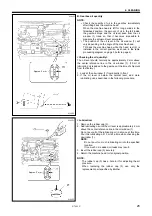

Approx.

2 mm

Approx.

4 mm

<-4[]3>

3773M

<-405>