- 32 -

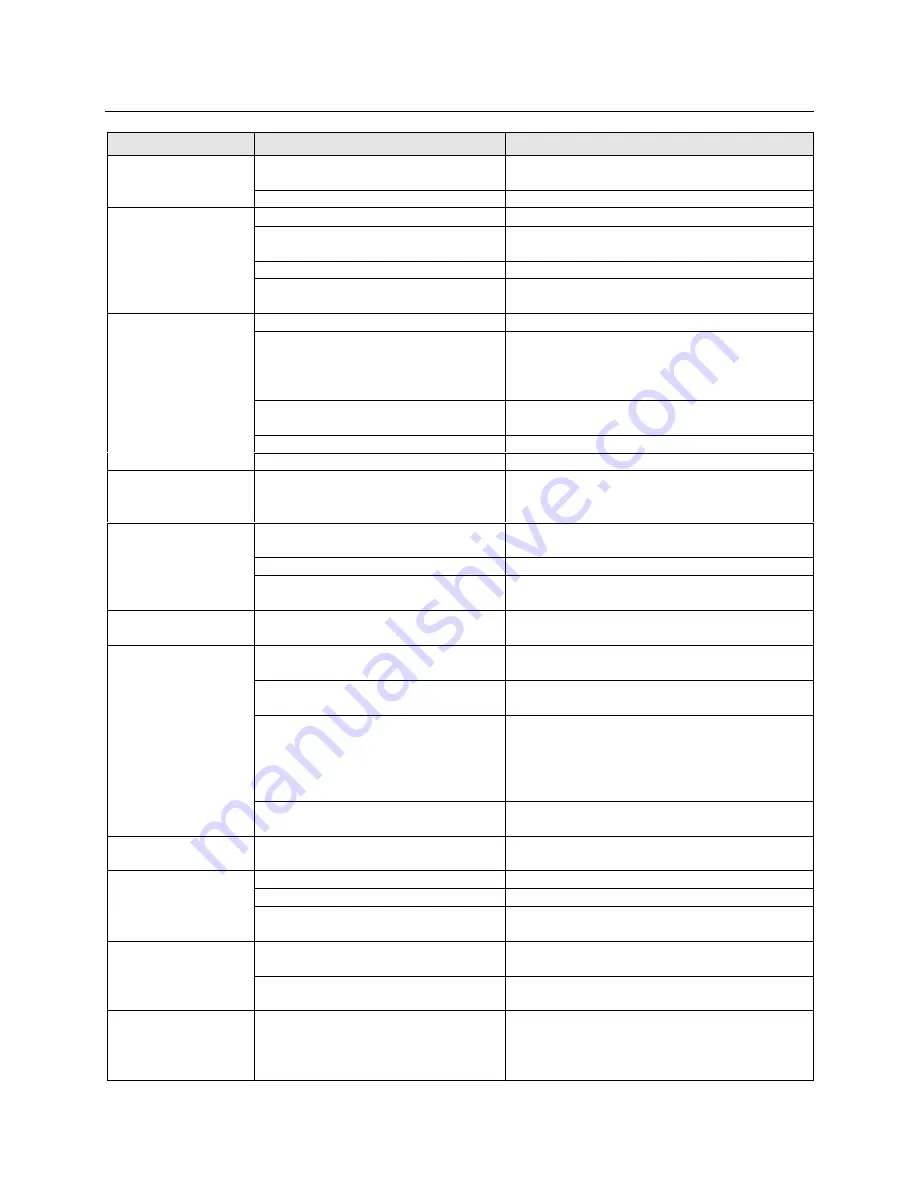

Troubleshooting

Problem

Cause

Solution

The AC adapter is not connected properly.

Check that the machine is plugged into a power

source.

No activity after the

machine has been

turned on.

The top cover is not completely closed.

Close the top cover.

The document was not set properly.

Reset the document properly and press Start again.

The document is too thick or too thin.

The minimum and maximum thickness of paper that

can be used with this machine are 0.1mm-0.2mm.

The document is wrinkled or curled.

Curled, wrinkled documents cannot be laminated.

The document will not

feed into the machine

and alert buzzer sounds

(two times).

The width of the document is too narrow or

too wide.

The width of the document must be between 2.2”

(55mm) and 8.5” (216mm).

The document is too small.

Documents must be at least 3.5” (90mm) long.

The wrong film cartridge is installed.

(US Letter/A4 paper cannot be laminated

when a 4.8 inch/A6 film cartridge is

installed in the machine.)

Install the proper film cartridge.

The length of the document is too long.

The length of the document must be less than 39.4”

(1000mm).

The film has run out.

Change the film cartridge.

Job stops during

processing, the Start

button blinks (in red)

and the alert buzzer

sounds.

The document is jammed.

Remove the jammed document.

Job stops during

processing, the Start

button blinks in orange.

Document length is more than 13.8”

(350mm) long.

Press Start to restart the process.

The document is too thick or too thin.

The minimum and maximum thickness of paper that

can be used with this machine are 0.1mm - 0.2mm.

The document is wrinkled or curled.

Curled, wrinkled documents cannot be laminated.

Output quality is poor.

The document is too small.

Documents must be at least 2.2” (55mm) wide and

3.5” (90mm) long.

The document will not

feed straight.

The document guide is not set properly.

Set the document guide properly.

The cutter units are not installed properly.

Check if the cutter units are installed in the machine

properly.

The thickness of the paper is too thick.

The maximum thickness of paper that can be used

with this machine is 0.2mm.

The cutter units have been damaged.

Replace the cutter units. You can replace the side

cutter units and corner cutter tray.

It is not possible to replace the top/bottom cutter. If

these cutter units do not work properly, please consult

your dealer.

The document is not cut

after processing.

Auto Cut Mode Off is selected.

Change the setting of the Auto Cut Mode selector

switch.

The cutting position is

not accurate (top/bottom)

The paper sensor is damaged.

Please consult your dealer.

Sticker film has not been loaded.

Use Brother Sticker Film Roll LC-A9 or LC-A5.

The liner of the sticker has not been peeled away.

Remove the liner.

Stickers will not stick.

The surface that the sticker is meant to

adhere to is dirty or rough.

Wipe the surface or try another surface.

The film cartridge is not installed properly or

an incompatible film cartridge is installed.

Install the film cartridge properly.

Use Brother authorized film cartridges and film refills only.

The Start button blinks

(in red) and the alert

buzzer sounds when the

machine is turned on.

The proper AC adapter is not being used.

Use a Brother authorized AC adapter.

The Start button blinks

(in red) and the alert

buzzer sounds when the

top cover is closed

The film cartridge is not installed properly

or an incompatible film cartridge is

installed.

Install the film cartridge properly.

Use Brother authorized film cartridge and film refills

only.

Summary of Contents for LX-900

Page 1: ...1 e H Owner s Manual ...