2-21

Confidential

4.3

Troubleshooting for Document Paper Feeding Problems

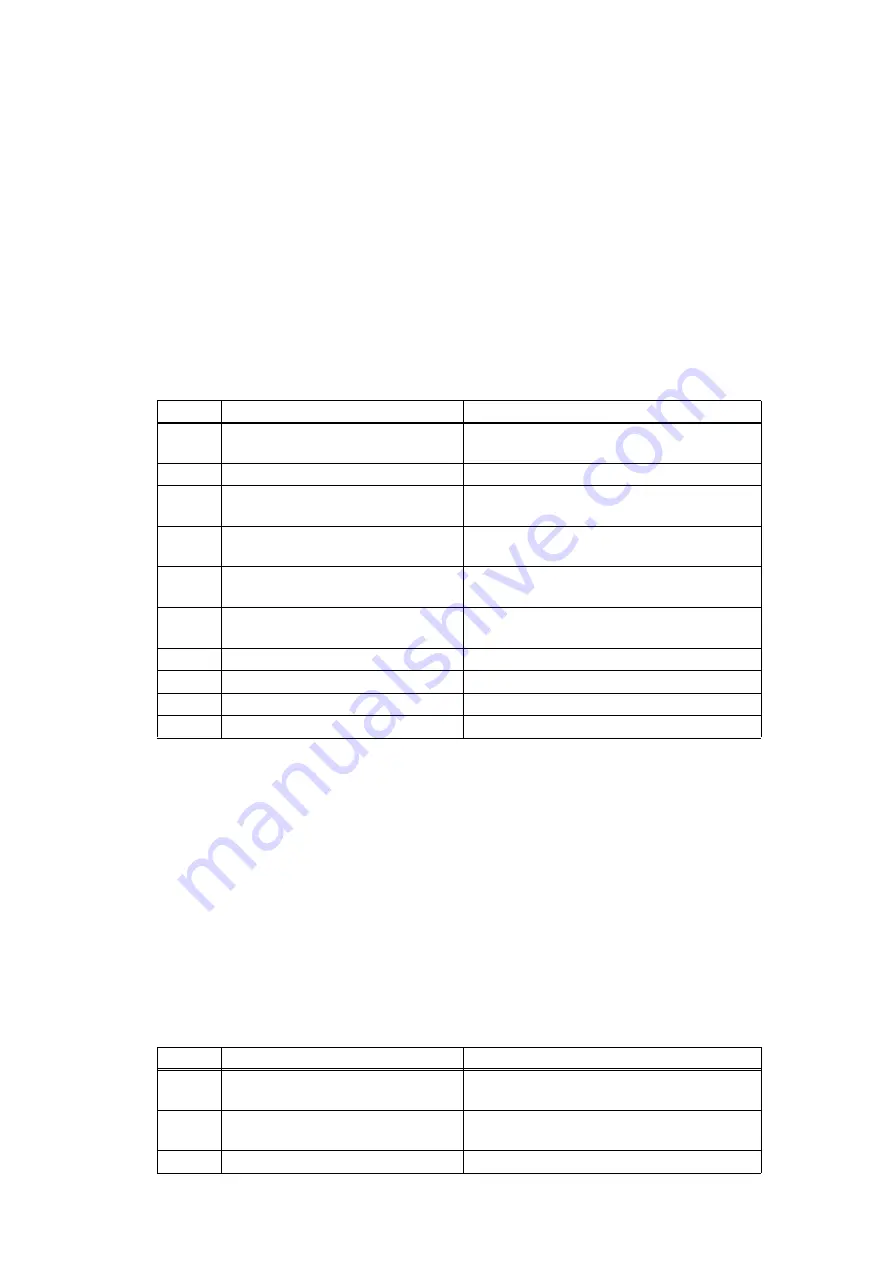

4.3.1 No document is fed

4.3.2 Multiple documents are fed

<User Check>

- Check that the paper used for the document is within the standard. If it is not within the

standard, use a carrier sheet (Models with carrier sheet only).

- Check that the number of documents set is within the standard.

- Check that the front cover is closed correctly.

- Moisten a soft cloth with cleaning solution. Gently and evenly wipe the pick up roller and

reverse roller perpendicular to the direction of the rotation with the cloth to clean it.

Note: Do not use any solution except the one packaged in the accessory (ethanol or

detergent on the market). Failure to keep this instruction may cause the roller

deterioration or machine break down.

- Replace the reverse roller and pick up roller.

Step

Cause

Remedy

1

Document detection actuator

coming off

Reattach the document detection actuator.

2

Front cover sensor attachment failure Reattach the front cover sensor.

3

Connection failure of the front cover

sensor harness

Reconnect the front cover sensor harness.

4

Connection failure of a feed motor

harness

Reconnect a feed motor harness.

5

Connection failure of the document

detection sensor PCB harness

Reconnect the document detection sensor

PCB harness.

6

Attachment failure of the gears in a

feeding system

Reattach the gears in a feeding system.

7

Front cover sensor failure

Replace the front cover sensor.

8

Document detection sensor failure Replace the document detection sensor PCB.

9

Feed motor failure

Replace a feed motor ASSY.

10

Main PCB failure

Replace the main PCB ASSY.

<User Check>

- Check that the paper used for the document is within the standard. If it is not within the

standard, use a carrier sheet (Models with carrier sheet only).

- Check that the document is not damp. If it is damp, dry it or use a carrier sheet (Models

with carrier sheet only).

- Check that the number of documents set is within the standard.

- Moisten a soft cloth with cleaning solution. Gently and evenly wipe the pick up roller and

reverse roller perpendicular to the direction of the rotation with the cloth to clean it.

Note: Do not use any solution except the one packaged in the accessory (ethanol or

detergent on the market). Failure to keep this instruction may cause the roller

deterioration or machine break down.

- Replace the reverse roller and pick up roller.

Step

Cause

Remedy

1

Incorrect multi feeding sensor

threshold setting

Reset the multi feeding sensor threshold.

2

Connection failure of the multi

feeding sensor harness

Reconnect the multi feeding sensor

harness.

3

Multi feeding sensor failure

Replace the multi feeding sensor.

Summary of Contents for ImageCenter ADS-2400N

Page 23: ...2 4 Confidential 2 2 Paper Feeding Fig 2 2 Feed path Front side Back side ...

Page 46: ...3 2 Confidential 2 PACKING ...

Page 49: ...3 5 Confidential 5 LUBRICATION There are no applicable parts for lubrication ...

Page 50: ...3 6 Confidential 6 OVERVIEW OF GEARS There are no gears to be disassembled ...

Page 96: ...4 3 Confidential 6 Click the Machine Info The firmware version is displayed ...