APPENDIX

59

4

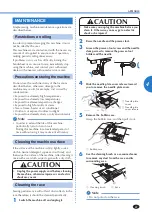

Upper thread tightened up

■

Symptom

• The upper thread appears as a single

continuous line.

• The lower thread is visible from the upper side

of the fabric. (Refer to the illustration below.)

• The upper thread has tightened up, and comes

out when pulled.

• The upper thread has tightened up, and

wrinkles appear in the fabric.

• The upper thread tension is tight, and the

results do not change even after the thread

tension is adjusted.

1

Lower side of fabric

2

Lower thread visible from upper side of fabric

3

Upper thread

4

Upper side of fabric

5

Lower thread

■

Cause

Incorrect lower threading

If the lower thread is incorrectly threaded, instead

of the appropriate tension being applied to the

lower thread, it is pulled through the fabric when

the upper thread is pulled up. For this reason, the

thread is visible from the upper side of the fabric.

■

Remedy/check details

Correctly install the lower thread.

• Refer to “Lower threading” (page 14-15).

Tangled thread on wrong side of

fabric

■

Symptom

• The thread becomes tangled on the lower side

of the fabric.

• After starting sewing, a rattling noise is made

and sewing cannot continue.

• Looking under the fabric, there is tangled

thread in the bobbin case.

■

Cause

Incorrect upper threading

If the upper thread is incorrectly threaded, the

upper thread passed through the fabric cannot be

firmly pulled up and the upper thread becomes

tangled in the bobbin case, causing a rattling

noise.

■

Remedy/check details

Remove the tangled thread, and then correct the

upper threading.

1

Remove the tangled thread. If it cannot be

removed, cut the thread with scissors.

• For details, refer to “Cleaning the race” (page

57).

2

Remove the upper thread from the machine.

3

Correct the upper threading by following

the instructions in “Upper threading” (page

15-17).

• If the bobbin was removed from the bobbin

case, refer to “Lower threading” (page 14)

and “Remedy/check details” in the section

“Upper thread tightened up” (page 59) to

correctly install the bobbin.

Incorrect thread tension

■

Symptoms

Symptom 1 : The lower thread is visible from the

upper side of the fabric.

Symptom 2 : The upper thread appears as a

straight line on the upper side of the

fabric.

Symptom 3 : The upper thread is visible from the

lower side of the fabric.

Symptom 4 : The lower thread appears as a straight

line on the lower side of the fabric.

Symptom 5 : The stitching on the lower side of

the fabric is loose or has slack.

Summary of Contents for 885-E33

Page 2: ......