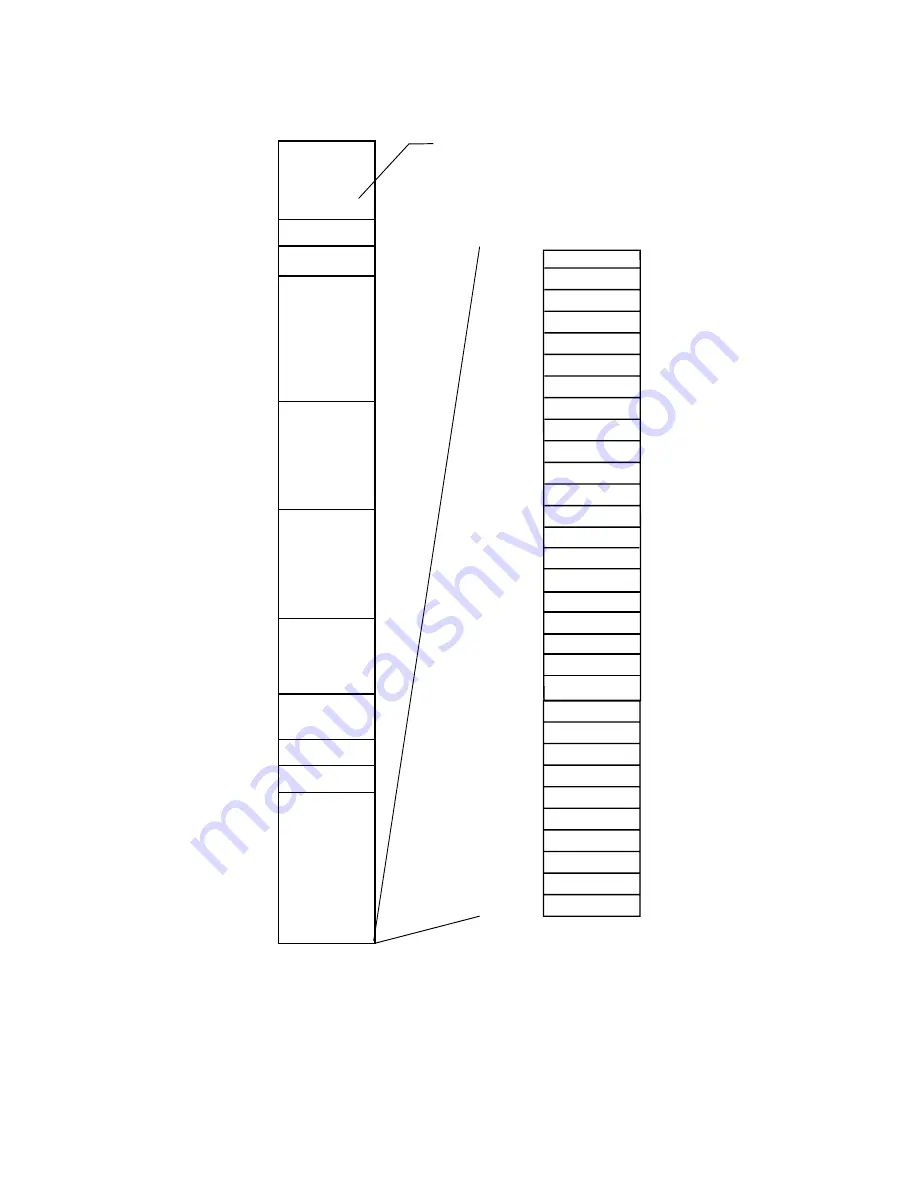

III -

4

0000_0000

0040_0000

0080_0000

0100_0000

0200_0000

0400_0000

0600_0000

0800_0000

0B00_0000

0C00_0000

0E00_0000

0FC0_0000

0FD0_0000

(256MB)

ROM

(4 bunk)

Font card

(64MB)

Font cartridge

(16MB)

ROM3

(128MB)

Ghost for CS1#

CPU

DRAM

(MAX 128MB)

64MB x 8 bunk

Reverved

(16MB x 4)

MIO / EOT

ASIC

Ghost for CS4#

There are 4 CS terminals for CSROM#0 - CSROM#3.

2MB or 4MB is selectable from CSROM#0 - CSROM#2.

If the both are selected, it will become one memory space

and ROM#0 supports upto 16MB. CSROM#3 is a rest of

the memory space with 256MB

$5E00_0000

$5E20_0000

$5E40_0000

$5E60_0000

$5E80_0000

$5EA0_0000

$5EC0_0000

$5EE0_0000

$5F00_0000

$5F20_0000

$5F40_0000

$5F60_0000

$5F80_0000

$5FA0_0000

$5FC0_0000

$5FFF

_FFFF

USB

HRC/GS setting

Memory wait setting

BD

LSB setting

Write to LSB

DRAM transfer

SDRAM mode setting

Soft support function

FC control setting

Memory structure

setting

Timer

Engine

CDCC

Easy serial 1

16550

Switching clock

Default setting

$5FE0_0000

Mediation level setting

Interruption

External interruption

Figure 3.2 Memory map

Summary of Contents for 1660e - B/W Laser Printer

Page 1: ...MECHANICS ELECTRONICS SERVICE MANUAL LASER PRINTER ...

Page 109: ...Appendix 3 Main PCB Circuitry Diagram 1 7 CODE UK3787000 B48K294 295CIR 1 7 NAME A 3 ...

Page 110: ...Appendix 4 Main PCB Circuitry Diagram 2 7 CODE UK3787000 B48K294 295CIR 2 7 NAME A 4 ...

Page 111: ...Appendix 5 Main PCB Circuitry Diagram 3 7 CODE UK3787000 B48K294 295CIR 3 7 NAME A 5 ...

Page 112: ...Appendix 6 Main PCB Circuitry Diagram 4 7 CODE UK3787000 B48K294 295CIR 4 7 NAME A 6 ...

Page 113: ...Appendix 7 Main PCB Circuitry Diagram 5 7 CODE UK3787000 B48K294 295CIR 5 7 NAME A 7 ...

Page 114: ...Appendix 8 Main PCB Circuitry Diagram 6 7 CODE UK3787000 B48K294 295 CIR 6 7 NAME A 8 ...

Page 115: ...Appendix 9 Main PCB Circuitry Diagram 7 7 CODE UK3787000 B48K294 295CIR 7 7 NAME A 9 ...

Page 116: ...Appendix 10 Control Panel PCB Circuitry Diagram 1 1 A 10 CODE NAME UK2527000 B48K143CIR ...

Page 117: ...Appendix 11 Scanner LD PCB Circuitry Diagram 1 1 A 11 CODE NAME UK2674000 B48K165CIR ...