30

Section D – Electrical Components

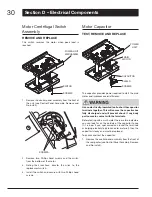

Motor Centrifugal Switch

Assembly

REMOvE AND REPLACE

This switch reverses the motor when peak load is

reached.

SWITCH

POWER UNIT

MECHANISM

SCREWS

Remove the control panel assembly from the front of

1.

the unit (see Control Panel Assembly, Remove and

Re-install).

SCREWS

Remove two Phillips head screws and the switch

2.

from the bottom of the motor.

Noting their locations, transfer the wires to the

3.

replacement switch.

Install the switch and secure with two Phillips head

4.

screws.

Motor Capacitor

TEST, REMOvE AND REPLACE

CAPACITOR

SHIELD

POWER

UNIT

MAIN

MOTOR

SCREWS

The capacitor provides power required to start the main

motor and improves overall efficiency.

Use an electrically-insulated tool to short the capacitor

terminals together. This will ensure the capacitor has

fully discharged and will prevent shock if any body

part comes in contact with the terminals.

Before testing with a multi-meter, there are two indicators

you can look for on the outside of the capacitor to see

if it is bad. If you spot corrosion around the terminals

or bulging electrolyte (ceramic outer material), then the

capacitor is leaky and must be replaced.

To access and test the capacitor:

Remove the control panel assembly from the front of

1.

the compactor (see Control Panel Assembly, Remove

and Re-install).