Pa

g

e

1

1

LEVEL ADJUSTMENT

Adjust the length of the top link so that the

machine is parallel (front to rear) to the ground

surface when operating at the desired depth.

TURNING

The machine should always be raised com-

pletely out of the ground when turning. This

will relieve stress on the shanks, mounting

hardware, and machine frame.

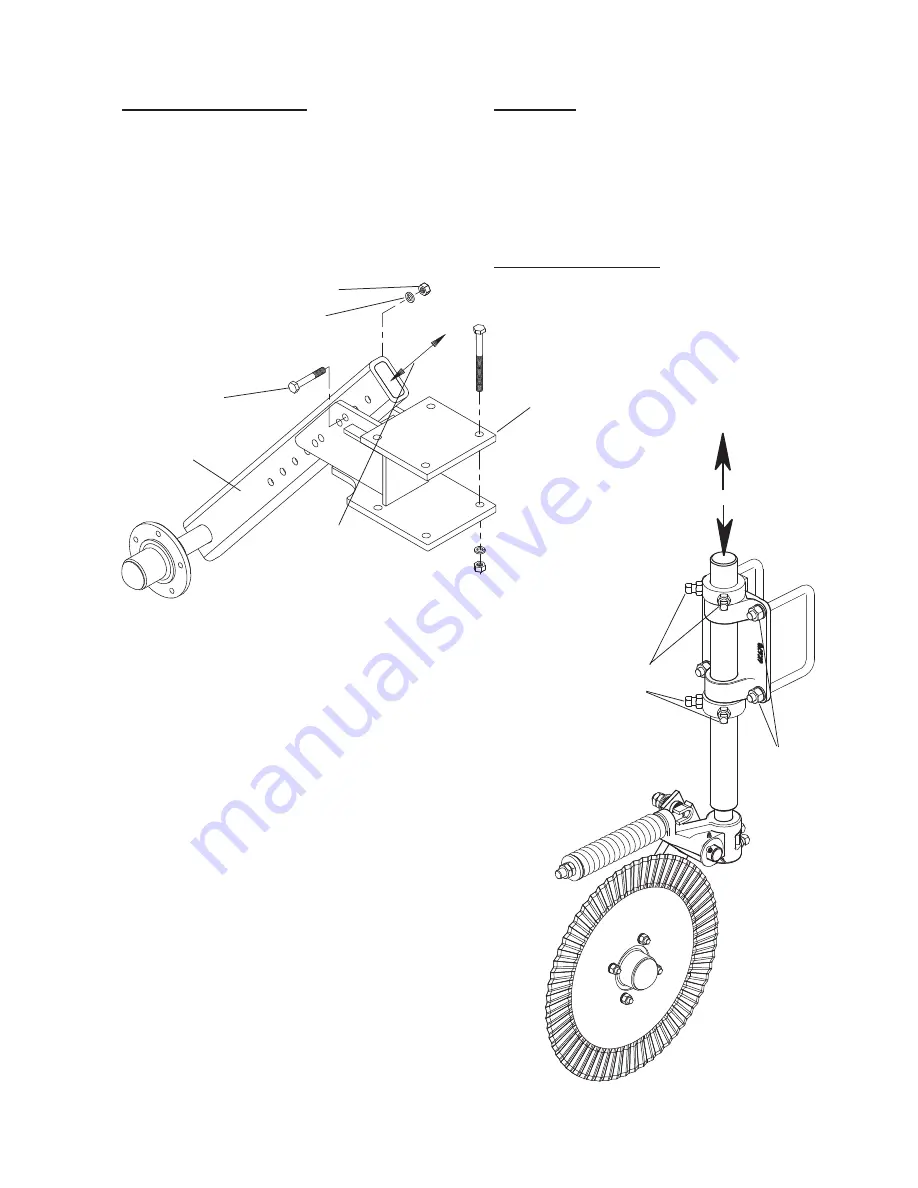

DEPTH CONTROL of SHANKS

Adjust the height of the manual

gauge wheel by removing the

bolts and sliding the gauge wheel

arm to the desired position within

the mount. Replace the bolts and

tighten before operating. See

Figure 4.

Manual Gauge Wheel

DEPTH CONTROL of

COULTER

ASSEMBLY

After the desired depth of the shanks have

been set, changes to the working depth of the

coulter blades can be made. Simply lower the

assembly by loosening the locking nuts and set

screws which hold the shaft. Adjust to desired

depth, make sure that the coulter stop is facing

forward to allow the coulter arm to swing side to

side. See Figure 7.

Tighten the set screws and the locking nuts.

LOCKWASHER, 5/8”

LOCK NUT, 5/8-11NC

HHCS, 5/8-11

NC X 9 1/2”

MOUNT

GAGE WHEEL

ADJUST HEIGHT

LOCK NUT

5/8-11

ADJUST HEIGHT

SET SCREWS

COULTER ASSEMBLY

Figure 4a

Figure 4b

9K308

604

Page 9

Summary of Contents for Compaction Commander 03 Series

Page 2: ...Page 2 9K308 604 Page 1...

Page 4: ...Page 4...

Page 25: ...Page 25 CCD5243 CCD5303 Figure 16e Figure 16f 30 0 30 30 30 48 24 48 0 24 9K308 604 Page 23...

Page 28: ...Page 28 72 96 72 48 48 96 0 24 24 CCD9243 Figure 16j 9K308 604 Page 26...

Page 29: ...Page 29 9K308 604rev10 4 05 Page 27 This Page Left Blank Intentionally...

Page 33: ......