Not for

Reproduction

4.

If any control fails to operate properly during testing or

seems to be out of adjustment, check and re-adjust it

according to the following

Adjustment Procedures section.

Safety Interlock System

This unit is equipped with safety interlock switches. These safety

systems are present for your safety, do not attempt to bypass

safety switches, and never tamper with safety devices. Check

their operation regularly.

Operational SAFETY Checks

Test 1 - Engine should NOT crank if:

• Forward speed control lever is not in the NEUTRAL position.

Test 2 - Engine SHOULD crank if:

• Forward speed control lever is in the NEUTRAL position.

Test 3 - Engine should SHUT OFF if:

• Operator releases the operator presence handles while the

forward speed control lever is not in the NEUTRAL position.

Test 4 - PTO Switch (blades) should SHUT OFF if:

• If the PTO switch is ON and the operator releases the

operator presence handles, OR

• The operator presses the PTO switch down to the OFF

position.

Test 5 - PTO Switch (blades) SHOULD turn on if:

• Operator depresses the operator presence handles and the

PTO switch is pulled up to the ON position.

Test 6 - Blade Brake Check (For model 5901441 only):

Mower blades and mower drive belt should come to a complete

stop within five (5) seconds after electric PTO switch is turned

OFF (or operator releases the operator presence handles). If

the mower drive belt does not stop within five (5) seconds, see

your dealer.

Test 6 - Blade Brake Check (For all other models):

Mower blades and mower drive belt should come to a complete

stop within seven (7) seconds after electric PTO switch is turned

OFF (or operator releases the operator presence handles). If

the mower drive belt does not stop within seven (7) seconds,

see your dealer.

Note: Once the engine has been stopped, the forward speed

control lever must be returned to the NEUTRAL position, the

parking brake should be engaged, the operator presence

handles should be depressed and the PTO switch should be in

the OFF position in order to start the engine.

WARNING

If the unit does not pass a safety test, do NOT operate it. See

your authorized dealer. Under no circumstance should you

attempt to defeat the purpose of the safety interlock system.

Adjustment Procedures

If any control fails to operate properly during testing or seems

to be out of adjustment, check and re-adjust it according to the

following instructions.

Cutting Height Adjustment

Cut Height Indication Chart

Cutting Height

Hole Number

1.5" (3,8 cm)

1

2.0" (5,1 cm)

2

2.5" (6,4 cm)

3

3.0" (7,6 cm)

4

3.5" (8,9 cm)

5

4.0" (10,2 cm)

6

4.5" (11,4 cm)

7

To adjust the cutting height:

1.

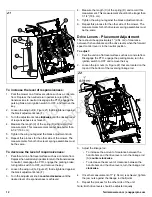

Use Figure 19 and the Cut Height Indication Chart to

determine the correct mounting holes for the desired cutting

height.

19

2.

Remove the hair pins (A, Figure 19) from the deck lift shafts

(C).

3.

Use the deck handle (B) and either raise or lower the cutter

deck to the desired cutting height. Re-install the hair pins

in the hole for the desired cutting height.

4.

Repeat the process for the other side of the machine. The

hair pins must be installed in the same numbered hole

in all four deck lift shafts for the mower deck to have a

level cut.

10