Operation and Safety Manual

™

300IX Gravity-feed Slicer

7

Operation

Things to keep in mind

1. The foodstuff should only be loaded onto the meat table with the thickness control set

to zero and the power switched off at the control panel.

Aside from being essential to your safety, these conditions keep the foodstuff to be

sliced (particularly if it is solid) from being accidently knocked against the cutting

edge of the blade, which could be damaged.

2. The recommended, and only safe way of moving the meat table during slicing

operations is either with the pusher handle.

3. The slicing movement should be done with a speed that is constant and appropriate to

the density and/or hardness of the foodstuff to be sliced. The general rule-of-thumb is

that the harder the foodstuff, the slower the slicing. Don't attempt to slice fresh meat

quickly, as too rapid a stroke will tear the meat.

Following this rule will result in a slice with a good, clean appearance, without putting

undue strain on either the cutting blade or the motor.

4. Sharpen the blade as soon as the sliced foodstuff begins to look ragged or roughened,

or when the effort required to slice increases significantly. Refer to the Maintenance

section for the correct procedure for blade sharpening.

Manual operation

Begin using the slicer by returning the thickness control to zero and making sure that the meat

tray carriage is pulled to the front of the slicer.

1. Draw the feed carriage (10) all the way towards the operator and the lift the Last Slice device (9).

2. Place the product to be sliced in the feed carriage (10), firmly against the carriage barrier

wall closest to the operator, and up against the Slice thickness plate (3). Place the Last Slice

device (9) on top of the product to be sliced.

3. Set the desired thickness of slice using the thickness control (5).

4. Switch the slicer on by pressing the green "ON" button at the front of the machine (4).

Immediately the blade will spin in an anti-clockwise direction.

5. Grasp the carriage pusher handle (8) firmly and push the product holder away from you

towards the back of the slicer. Once the slice has been cut, pull the meat table back towards

you.

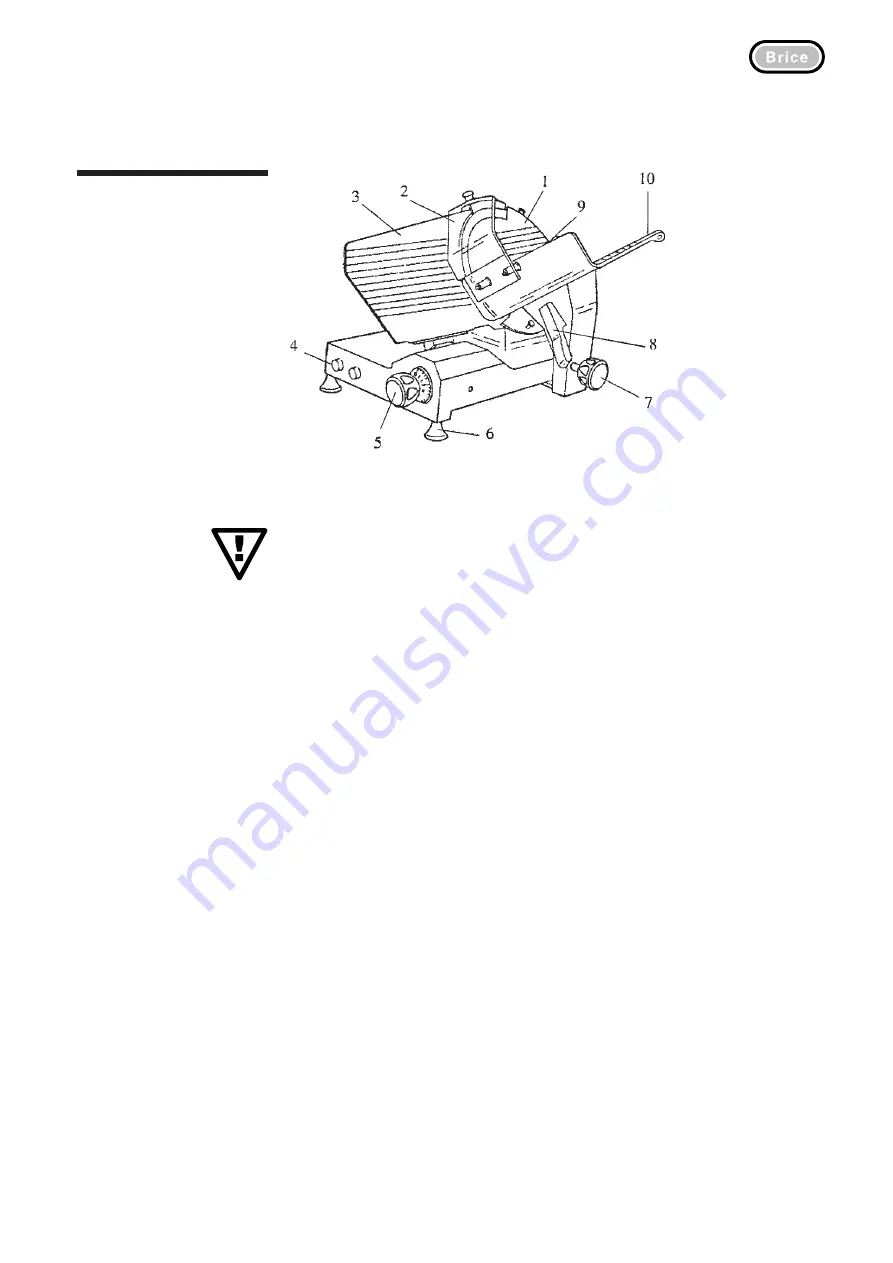

1 Blade cover

2 Finger guard

3 Slice thickness plate

4 ON/OFF controls

5 Slice thickness control

6 Feet

7 Carriage locking knob

8 Carriage pusher handle

9 Last slice device (LSD)

10 Food carriage

11 Sharpener

12 Sharpener locking knob