13

User Manual

7

Maintenance

7.1

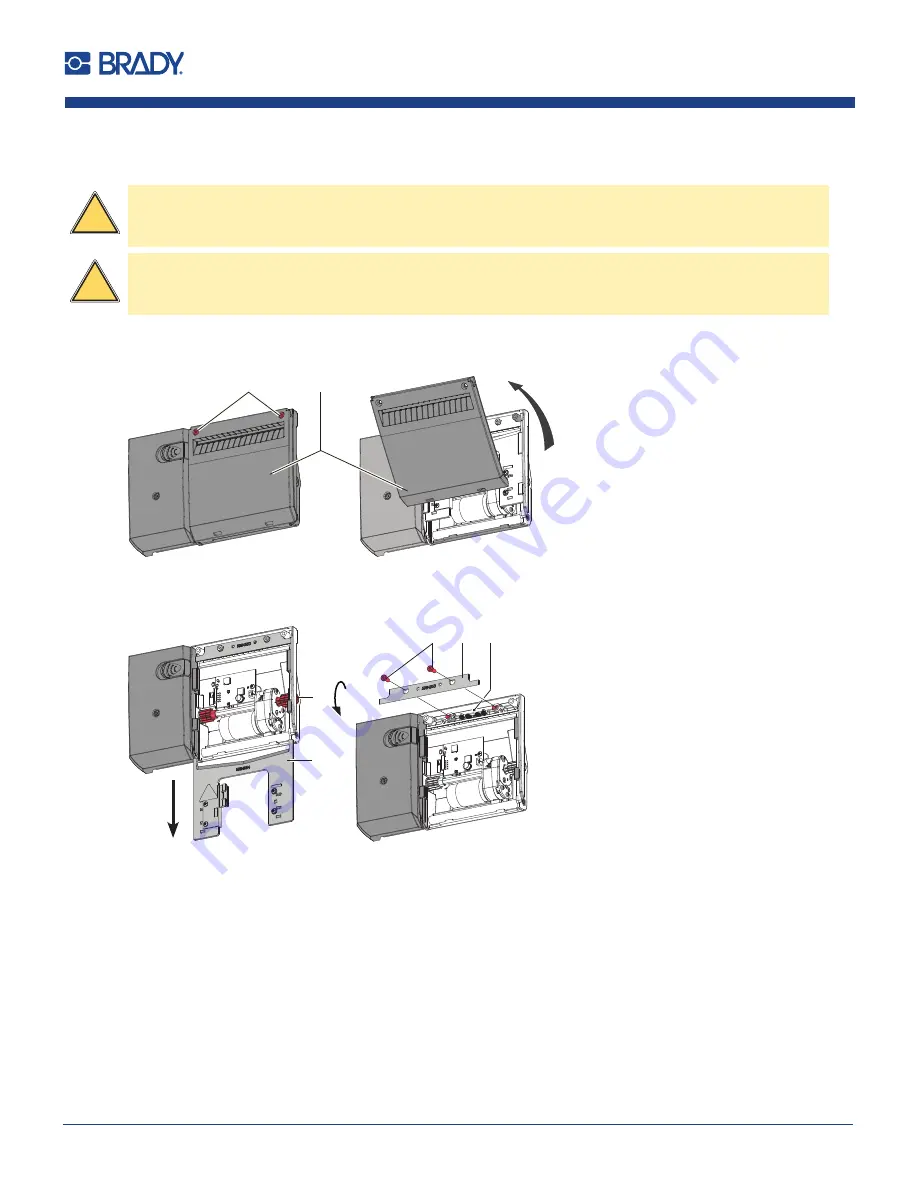

Removing the Blades for Cleaning and Replacement

!

Warning!

Disconnect the printer from the electrical outlet.

!

Caution!

Risk of injury. The cutter blades are sharp.

To clean the blades, they must be removed.

1.

Disassemble the NG Guillotine Cutter from the printer.

1

2

2.

Loosen screws (1) and remove cover (2) towards the front.

6

5

7

3

4

3.

Using a 2.5mm hex wrench to turn the axle (3) counterclockwise. The lower blade (4) is moved down until it can be

pulled out.

4.

Loosen screws (5).

5.

Fix the upper blade (6) while the springs (7) press against the

upper blade (6).Remove the upper blade (6) and make sure that the springs (7) do not fall out.