18

BPP11 User Manual

CHAPTER 4

LED and Button Functions

This printer has one button and one three-color LED indicator. By the button when the LED

indicates a different color, the printer can be set to feed labels, pause the printing job, select

and calibrate the media sensor, print a printer self-test report, reset the printer to defaults

(initialization). See the following button operation descriptions for functions.

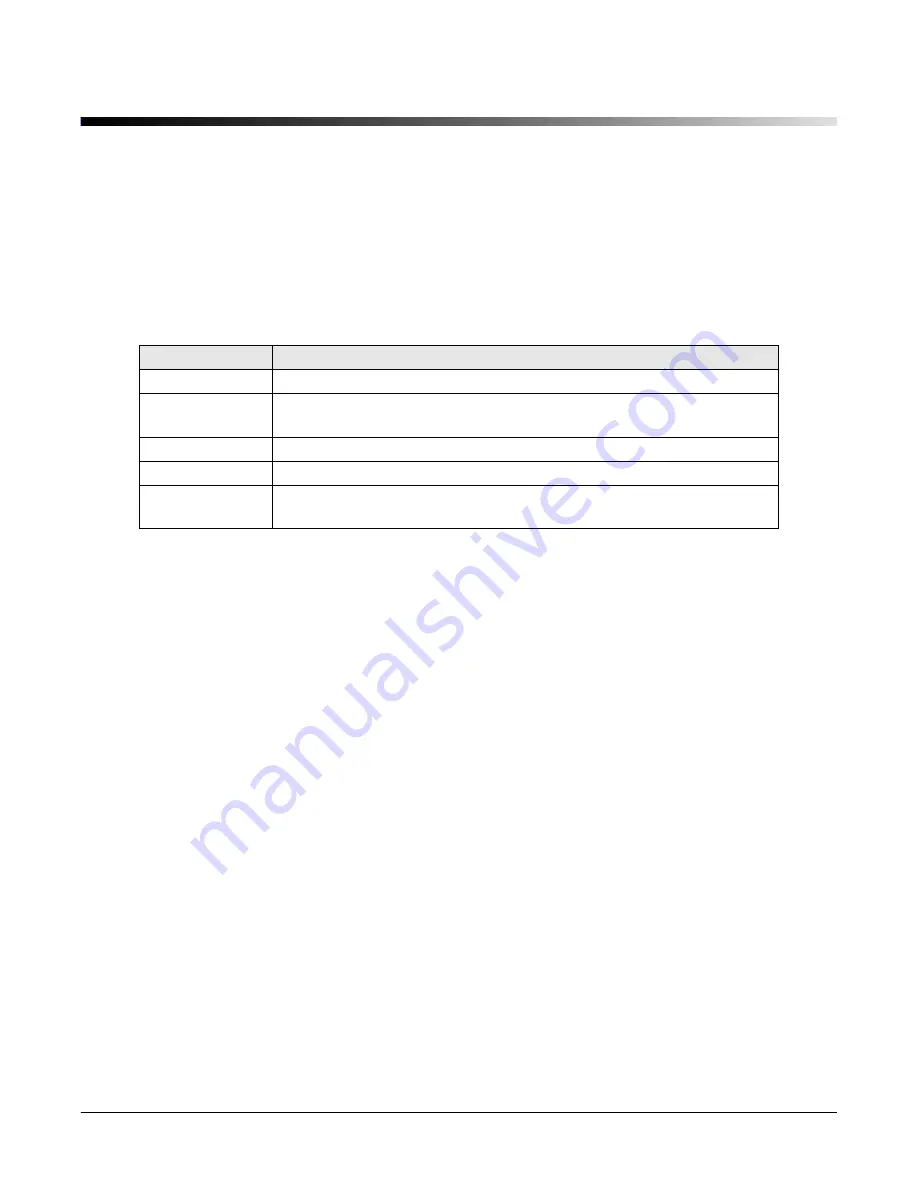

LED Indicator

Regular Button Function

1.

Feed labels

:

When the printer is ready, press the button to feed one label to the beginning of the next

label.

2.

Pause the printing job

:

When the printer is printing, press the button to pause a print job. When the printer is

paused the LED will blink green. Press the button again to continue the printing job.

LED Color

Description

Green/ Solid

Illuminates when power is on and the device is ready to use.

Green/ Flash

Illuminates when the system is downloading data from PC to

memory or the printer is paused.

Amber

Illuminates when the system is clearing data from printer.

Red / Solid

Illuminates when the printer head is open, or a cutter error.

Red / Flash

Illuminates when there is a printing error, such as

h

ead open, paper

empty, paper jam, ribbon empty, or memory error etc.

Summary of Contents for BBP11-34L

Page 1: ...Thermal Transfer Printer User Guide BBP11 34L Ed 08 09...

Page 14: ...10 BPP11 User Manual Ribbon Loading Path...

Page 32: ......