44

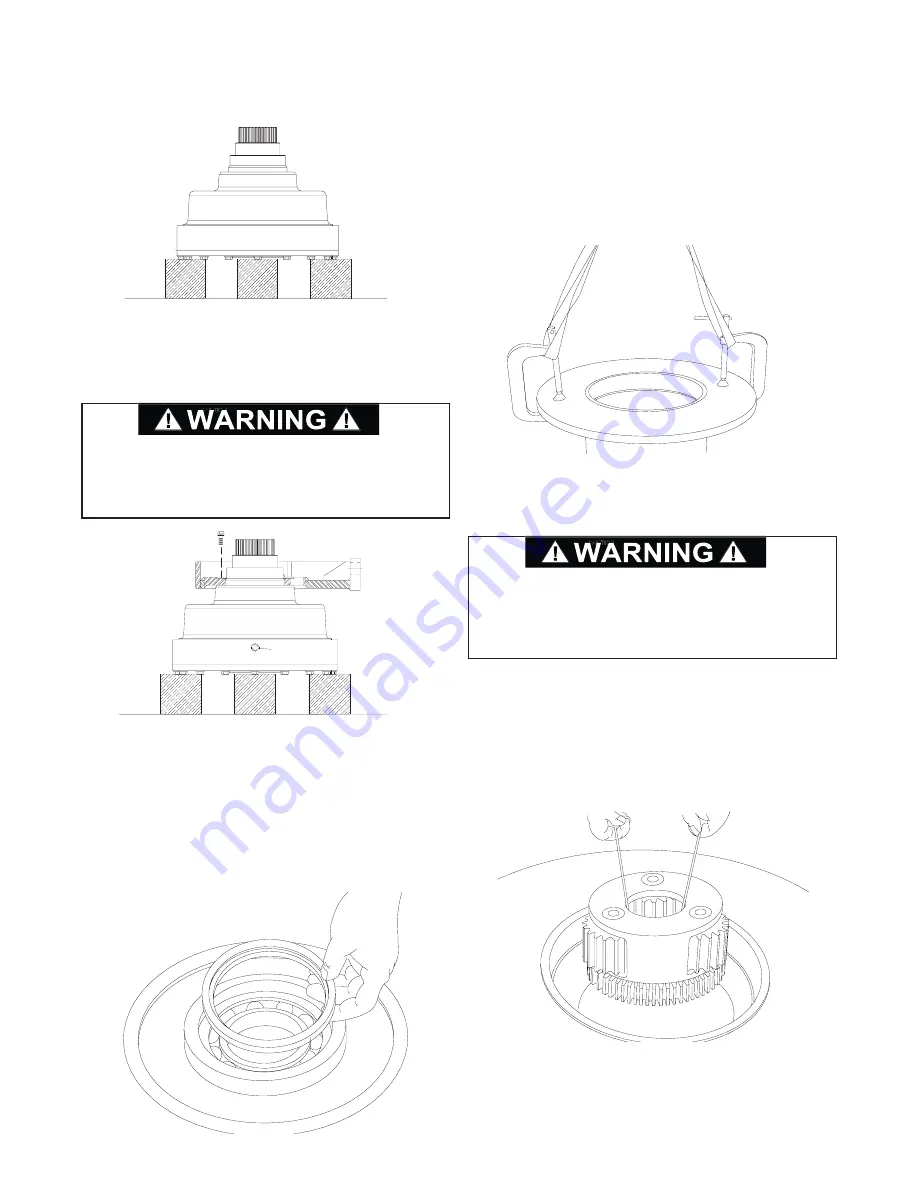

1. Clean all parts before reassembling.

2. Place the auxiliary brake assembly on a stable plat-

form at or near floor-level with the brake shaft facing

up. Use support blocks as needed to provide stabil-

ity.

3. Place the support end plate over the brake housing.

Position the end plate such that the mounting pad is

to your RH side when looking directly at the brake

release port in the brake housing. Apply Loc-Tite

242 to clean, dry bolt threads and install the bolts

with 110 lb-ft (150 N-m) torque.

4. Lubricate the seal and bearing surfaces on the

brake housing.

5. If necessary, install the bearing into the cable drum

bore, ensuring that it is fully seated against the

shoulder in the bottom of the bore. Apply sealing

compound to the outside diameter of the oil seal.

Turn the spring side of the seal toward the bearing

and press the seal into bore by applying constant,

even pressure. The seal is fully installed when the

outer surface is located flush to the drum face.

6. Turn the drum over and place it onto the brake shaft.

Be careful while lowering the drum into position to

keep from damaging the drum seal.

NOTE:

Due to attempting to align both the drum

bearing and the splines on the brake shaft simulta-

neously, it may be necessary to release the auxiliary

brake to aid assembly. Use the hand pump as

described in the test procedure for the auxiliary

brake to release the brake and allow the brake shaft

to move slightly, aiding drum alignment.

7. Lower the output planet carrier assembly into the

cable drum, making sure the teeth on the planet car-

rier mesh with the teeth in the cable drum.

HOIST ASSEMBLY

The auxiliary brake assembly weighs approximately

390 lbs (177 kg). Use the proper precautions when

handling these parts to eliminate the possibility of

component damage or personal injury.

A -01 cable drum weighs approximately 315 lbs (143

kg). Use the proper precautions when handling these

parts to eliminate the possibility of component dam-

age or personal injury.

Brake

Release Port