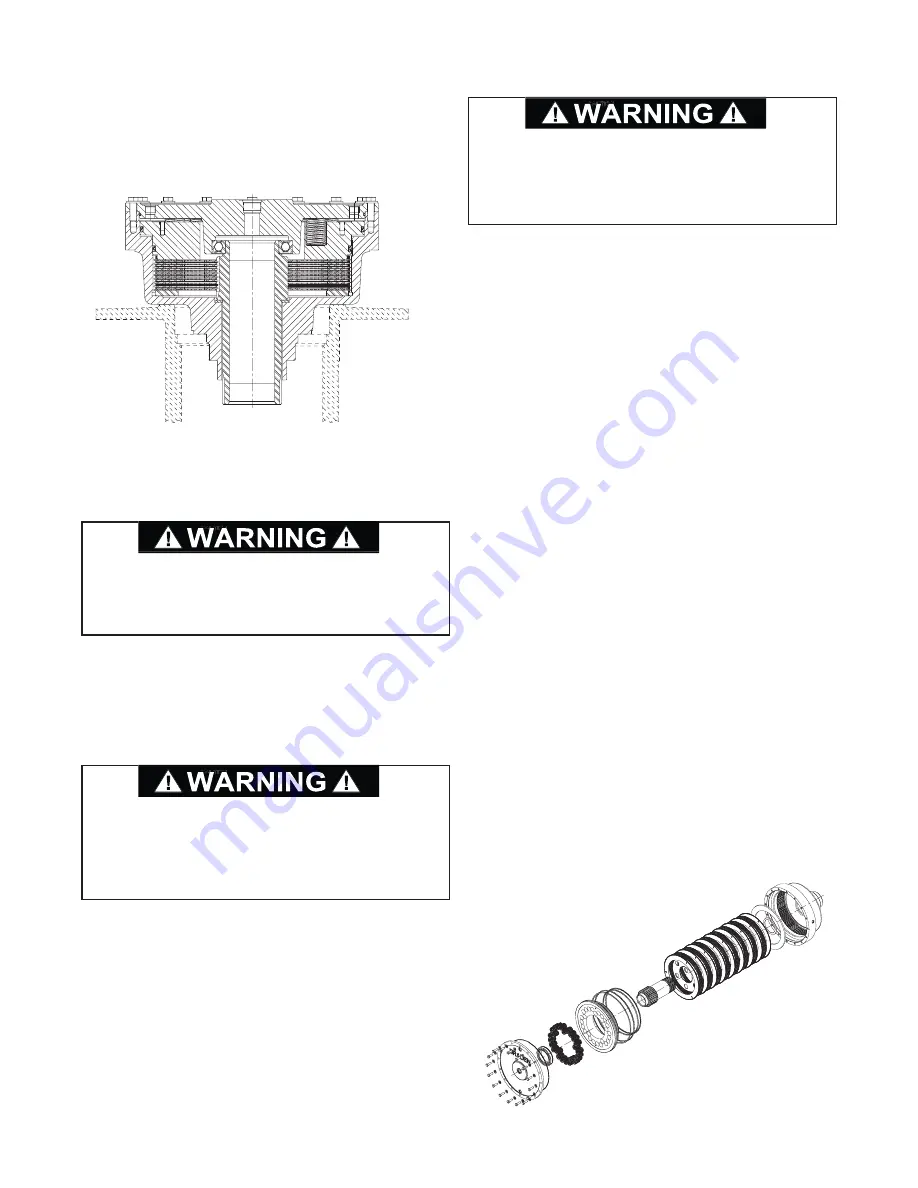

1. Carefully turn the auxiliary brake assembly over and

place it with the end cover facing upward. Use the

proper precautions to keep from damaging the bear-

ing and seal surfaces at the end of the brake hous-

ing.

NOTE:

Place the cable drum on the floor with the

motor end facing up. This will provide a stable plat-

form in which to locate the auxiliary brake assembly

to allow proper servicing.

2. Carefully loosen the capscrews in a slow, alternat-

ing manner to remove the spring force on the brake

housing cover. Remove the brake housing cover

and discard the o-ring. The ball bearing at the end

of the brake shaft may come out with the cover.

Take care to not drop it.

3. Remove the brake springs. Inspect the springs for

damage or deformation. Check the spring free

length which should be no less than 1.938 in. (49

mm). If any spring is damaged or of incorrect length,

replace ALL springs.

4. Using 3/8-16 UNC eyebolts inserted in the lifting

holes, lift the piston out of the housing. Tap the

edges of the housing with a soft hammer to break

the suction and relieve the seal drag between the

piston and housing.

5. Remove and discard the o-rings and back-up rings

from the piston. Inspect the piston groves for

scratches, burrs or other damage.

6. Remove the brake plates, friction discs and spacer

from the housing.

7. Lay the friction plates on a clean, flat surface and

check for distortion or warpage. The friction sur-

faces should be well defined with visible oil grooves.

The splines should be uniform and square-ended. If

they are worn to a point, they should be replaced.

8. Inspect the steel brake plates in the same manner

as the friction plates. Check for distortion, warpage

or discoloration indicating excessive heat. Replace

as required.

9. Remove the brake shaft and thrust washer. Inspect

the bearing surfaces of the brake shaft for wear or

damage. Inspect the splines at both ends of the

shaft for burrs or other damage. The large splines

should have no indentions that would impair the

ability of the brake plates to slide smoothly during

brake release. Ensure the thrust washer is smooth

and flat.

10. Inspect the splines in the brake housing to ensure

there are no indentions can cause the brake plates

to hang up in operation, impairing their ability to

slide during brake release. Also, ensure the oil pas-

sage is clear of obstructions and the sealing sur-

faces are not scratched or otherwise damaged.

AUXILIARY BRAKE SERVICE

40

The auxiliary brake assembly weighs approximately

390 lbs (177 kg). Use the proper precautions when

handling these parts to eliminate the possibility of

component damage or personal injury.

The brake housing cover is under direct spring force

of approximately 2,000 lbs (907 kg). Use extreme

caution when removing the cover capscrews. Use of

careless or improper disassembly methods can

result in severe injury or death.

The brake piston weighs approximately 78 lbs (35

kg). Use the proper precautions when handling these

parts to eliminate the possibility of component dam-

age or personal injury.

AUXILIARY BRAKE ASSEMBLY