CAUTION

: Do not perform service or maintenance Operations with backhoe raised off the ground. For

additional access to tractor components removes backhoe.

Important

Securely support backhoe and relieve pressure in hydraulic lines prior to performing any service or maintenance operations

on the tractor or backhoe.

CAUTION

: Escaping fluid under pressure can have sufficient force to penetrate the skin, causing serious injury,

before disconnecting lines, be sure to relieve all pressure. Before applying pressure to the system, ensure all connections

are tight and that lines, pipes and hoses are not damaged. Fluid escaping from a very small hole can be almost invisible.

Use a piece of cardboard or wood rather than your hands

to search for suspected leaks. If injured by escaping fluid, seek medical attention immediately. Serious

infection or reaction can develop if correct medical treatment is not administered immediately.

Refer to “lubrication and Maintenance Chart” for quick reference to Maintenance Operations.

CAUTION:

Do not operate the backhoe if the fittings are leaking or if the hoses are damaged. A sudden line

burst could cause the boom, dipper arm or bucket to drop suddenly, causing damage to the tractor or backhoe or

injury to personnel.

CAUTION:

OPERATE THE BACKHOE FROM THE OPERATOR SEAT ONLY.

CAUTION

: Do not stand or walk under a raised backhoe. Accidental movement of control lever or

leak

in hydraulic system could cause boom or dipper arm to drop, causing severe injury.

[24]

Model

BHM-195

BHL-225

Structure weight (kg)

540

700

Max digging depth (m) A

1.95

2.25

Max digging radius (m) B

2.9

3.3

Max digging height (m) C

3.17

3.45

Max unloading height (m) D

2

2.3

Stabilizer width (m)

1.7

1.7

Swing angle for boom

180

180

Bucket turning angle

195

203

Bucket turning angle

0.02

0.035

Bucket width (mm)

15L/MIN

25L/MIN

Min. hydraulic flow req.

25L/MIN

40L/MIN

Max. hydraulic flow allowed

13MPA

13MPA

Min. hydraulic press. Allowed.

16MPA

16MPA

Bucket digging force (kg)

1100

1700

Dipper arm digging force (kg)

850

1100

Item

Service

Service Interval

Hydraulic System Oil Level

Check

Daily / 10 Hours

Hydraulic System Oil/Filter

Replace

Every 50 Hours

Tyre Inflation

Check

Weekly / 50 Hours

Backhoe Pivot Points

Lubricate / Grease

Daily / 10 Hours

Backhoe Hydraulic Lines, Hoses,

Connections

Check for leaks, wear

Daily / 10 Hours

Boom, Arm, Swing and Bucket

cylinder rod packing’s

Check for seepage, service as

needed

Daily / 10 Hours

Pivot Pin Bolts and Dust Covers

Check, replace if missing

Daily / 10 Hours

Pin Wear

Check, replace if necessary

Daily / 10 Hours

Backhoe Mount Hardware

Check visually

Daily / 10 Hours

Structural Bolts and Nuts

Re-torque

Every 25 Hours

PROBLEM

Possible Cause

Correction

Low hydraulic fluid level

Check and replenish hydraulic

fluid.

Hydraulic hoses connected

improperly

Check and correct hydraulic hose

connections.

Stabilizer Legs, Swing, Boom, Dipper

Arm and Bucket Cylinders not

working

Hydraulic hoses to / from control

valve blocked

Check for damage (kinked) hoses,

etc.

Backhoe control valve or tractor

main relief valve stuck open

Check system pressure, repair or

replace relief valve. Refer to the

tractor Operator’s Manual.

Lower system pressure supplied

from hydraulic pump

Check system pressure. Repair or

replace pump.

Control valve linkage broken

Inspect. Repair as required.

Quick disconnected coupler(s) are

not fully connected or “flow Check”

Check coupler connections.

Replace coupler(s) if necessary.

PROBLEM

Possible Cause

Correction

Stabilizer Legs, Swing, Boom, Dipper

Arm and Bucket Cylinders not

working

Hydraulic Hose or tube line blockage

Check for evidence of damage to

hoses or tube lines that would block

flow of oil between cylinders and

control valve

Cylinder piston assembly defective

(not sealing)

Check cylinder for internal leakage as

described in service section under

cylinder leakage tests.

Control Valve blockage

Inspect for blockage. Disassemble

valve if necessary.

Safety lock pins (2) not removed

Remove and store safety pins.

Stabilizer legs safety clip not released Release the clip

Cylinders operate in wrong direction

relative to control valve lever

position.

Hydraulic Hoses connected

incorrectly.

Correct hydraulic hoses connections.

Low hydraulic fluid level

Check and replenish hydraulic fluid.

Cold hydraulic fluid

Allow hydraulic system to warm up

to operating temperature

Summary of Contents for BHL-225

Page 1: ......

Page 7: ...6...

Page 8: ...7...

Page 16: ...15...

Page 24: ...23...

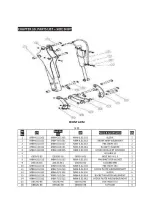

Page 30: ...FRONT ARM 29...

Page 31: ...MAIN BOOM 30...

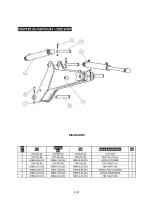

Page 32: ...SWING JOINT 31...

Page 33: ...SIDE SHIEFT FRAME 32...

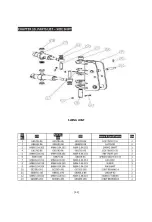

Page 34: ...BASE 33...

Page 35: ...OPERATION PANNEL AND OIL TANK 34...

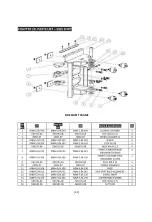

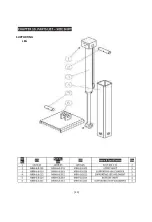

Page 36: ...SUPPORTING LEG 35...

Page 37: ...SEAT 36...

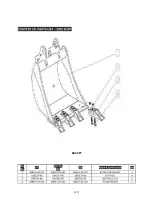

Page 38: ...BUCKET 37...

Page 39: ...FRONT ARM ASSEMBLY 38...

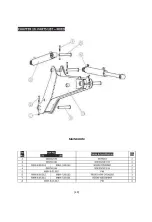

Page 40: ...MAIN BOOM 39...

Page 41: ...40...

Page 42: ...BOTTOM SEAT ASSEMBLY 41...

Page 43: ...SWING POST ASSEMBLY 42...

Page 44: ...SEAT 43...

Page 46: ...45...