CAUTION

: Backhoe should be mounted to the tractor

three point linkages.

CAUTION

: Never operate backhoe without secured solid top link and A-frame.

CAUTION:

Never store backhoe without bucket attached to the backhoe.

CAUTION

: Keep Feet and Hands well clear of underside of backhoe.

CAUTION

: Never raise 3.P.L position / draft lever while backhoe is connected, damage could

occur to linkage and hydraulic system. Use mechanical means to secure these levers down to

tractor.

CAUTION

: It is owner / Operator responsibility to ensure that the tractor 3.P.L top link & Hydraulic

lift cover area is strong enough to accept 3.P.L rigid connection and backhoe while in operation as

extra forces are exerted through top link. No liability can be accepted for damage to tractor.

CAUTION

: The backhoe unit when not fully connected to the tractor is potentially unstable. Proceed

with Caution. Do not raise the backhoe boom until it is fully connected to the tractor. Failure to

comply with these requirements could cause death, bodily injury or property damage.

CAUTION

: Do not operate the Backhoe if the fittings are leaking or if the hoses are damaged. A

sudden line burst would cause the boom to drop suddenly potentially causing death, bodily injury

or property damaged.

CAUTION

: Before disconnecting hydraulic lines, turn the tractor off, relieve all hydraulic pressure.

Escaping hydraulic oil under pressure can have sufficient force to prevent the causing serious

personal Injury.

CAUTION:

The tractor/backhoe should only be

operated with all safety equipment properly installed.

Keep assistants or bystanders a safe distance from the equipment operating area.

6.1 PRECAUTIONARY NOTE.

-Read and understand this manual to avoid accident.

-Check the hydraulic lines are correctly attached and not leaking.

-Maintain and repair (if it is needed) all parts or assemblies, check bolts and pins to be sure they are positioned tightly.

-Check tractor is prepared for operation. Refer tractor operators manual.

-Warm up and operate the tractor and backhoe carefully. Purge any air in the hydraulic lines and cylinders by fully cycling all

cylinders several times.

-Check hydraulic level in the tank to be at specified level. Add as required.

-

Do not operate the hydraulics when not seated in the backhoe operator’s seat/

-Keep all assistants out of area of operation.

[16]

Summary of Contents for BHL-225

Page 1: ......

Page 7: ...6...

Page 8: ...7...

Page 16: ...15...

Page 24: ...23...

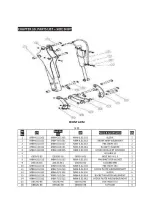

Page 30: ...FRONT ARM 29...

Page 31: ...MAIN BOOM 30...

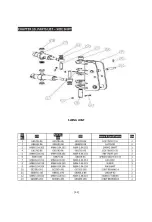

Page 32: ...SWING JOINT 31...

Page 33: ...SIDE SHIEFT FRAME 32...

Page 34: ...BASE 33...

Page 35: ...OPERATION PANNEL AND OIL TANK 34...

Page 36: ...SUPPORTING LEG 35...

Page 37: ...SEAT 36...

Page 38: ...BUCKET 37...

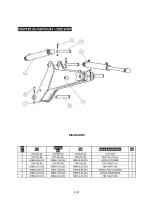

Page 39: ...FRONT ARM ASSEMBLY 38...

Page 40: ...MAIN BOOM 39...

Page 41: ...40...

Page 42: ...BOTTOM SEAT ASSEMBLY 41...

Page 43: ...SWING POST ASSEMBLY 42...

Page 44: ...SEAT 43...

Page 46: ...45...