5-4

Section 5 • Care & Maintenance

345 Conquest

Rub Rail Care

The rub rail on your boat is constructed of an injected

high density

PVC vinyl

material which laboratory

tests have proven to be highly resistant to staining,

fading and cracking.

As resilient as this material is, you still need to follow

some basic maintenance precautions.

General maintenance requires a thorough cleaning

with mild soap & water.

DO NOT

use any cleaning

agents which contain chemicals.

Although the outer shell is tough and durable, there

is a chance that it can be breached. Use care when

docking or exposing the rub rail to conditions which

may cause damage such as docking against heavily

barnacle-encrusted pilings.

Cleaning Fiberglass and Non-Skid

To protect your deck and non-skid areas from the

deteriorating affects of the sun, oxidation, water

spots and pollution, use a good quality “fiberglass

and non-skid deck” wax every two to three months.

When applied to your deck and non-skid areas, as

recommended by the manufacturer, the wax forms a

protective non-slick surface which will keep debris

from sticking. Dirt, soot, bird droppings, and even

fish blood will rinse right off.

The cleaner your stainless trim and fittings can

be kept, the greater the assurance of optimum

corrosion resistance. Without proper care even

the best stainless steel will corrode.

Stainless steel is strong and corrosion resistant, but

still requires maintenance to keep its appearance.

Frequent routine cleaning of your stainless steel

with a mild soap and water solution and coating with

a good grade cleaning wax will help maintain the

finish.

• Wash with mild soap and cold or

lukewarm water.

Stainless Steel Care

NOTICE

Masking tape is NOT recommended for the types

of paint you will be using.

NOTICE

NEVER use abrasive cleaners, detergents or soft

scrub type cleaners to wash your boats surfaces.

NEVER use abrasive pads, brushes or sponges

to attempt to remove stubborn stains.

NEVER use strong solvents or detergents which

contain chlorine.

preparing the old painted surface following the paint

manufacturer’s recommendations.

Follow the paint manufacturer’s recommendation for

applying the paint. Humidity and weather will play

a role in how and when the paint is applied. Several

thin layers are better than one thick layer.

To determine the waterline, you will need to place the

boat in water with a full load of fuel and gear. Mark

the waterline and measure above the marked line

1 to 3 inches for placement of the tape line.

Make sure that there is enough paint left to cover

areas that were not accessible, (slings, jack stands

etc.) and paint accordingly. Follow the

paint

manufacturer’s recommendation for do’s and dont’s

after the painting is complete.

NOTICE

Painting your boat’s hull will adversely affect the

boat’s speed and performance and may require

re-propping if the maximum engine RPMs

drop below the engine model/manufacturer

recommended operating range.

Some tears (cleanly sliced) can be repaired with a

“Super Glue” type product.

Thoroughly clean and dry the affected area. Apply

glue and hold the surfaces together.

Areas which have been torn or are affected by heavy

abrasion will have to have the damaged section

replaced. Please see your Boston Whaler dealer for

this type of repair.

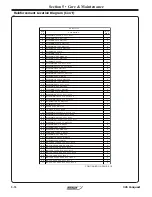

Summary of Contents for CONQUEST 345

Page 21: ...xix 345 Conquest THIS PAGE INTENTIONALLY LEFT BLANK...

Page 93: ...2 46 Section 2 General Information 345 Conquest THIS PAGE INTENTIONALLY LEFT BLANK...

Page 150: ...4 16 345 Conquest Section 4 Electrical System Batteries Joystick Steering Option Fig 4 16 1...

Page 152: ...4 18 345 Conquest Section 4 Electrical System DC MDP Joystick Steering Fig 4 18 1...

Page 154: ...4 20 345 Conquest Section 4 Electrical System AC Power 220V 50Hz Fig 4 20 1...

Page 156: ...4 22 345 Conquest Section 4 Electrical System Cabin O H and Accent Lights Fig 4 22 1...

Page 158: ...4 24 345 Conquest Section 4 Electrical System Wipers and Washers Fig 4 24 1...

Page 160: ...4 26 345 Conquest Section 4 Electrical System Waste System Fig 4 26 1...

Page 161: ...4 27 Section 4 Electrical System 345 Conquest Section 4 Electrical System Windlass Fig 4 27 1...

Page 162: ...4 28 345 Conquest Section 4 Electrical System Trim Tabs Fig 4 28 1...

Page 166: ...4 32 345 Conquest Section 4 Electrical System Pumps Sheet 2 Fig 4 32 1...

Page 168: ...4 34 345 Conquest Section 4 Electrical System V Berth Schematic Fig 4 34 1...

Page 170: ...4 36 345 Conquest Section 4 Electrical System Shore Power 230V 50HZ Fig 4 36 1...

Page 172: ...4 38 345 Conquest Section 4 Electrical System Stereo Premium Option Fig 4 38 1...

Page 174: ...4 40 345 Conquest Section 4 Electrical System Heater CO Monitor Fig 4 40 1...

Page 176: ...4 42 345 Conquest Section 4 Electrical System Generator 230V 50Hz Fig 4 42 1...

Page 178: ...4 44 345 Conquest Section 4 Electrical System STBD AC Harness Fig 4 42 1...

Page 180: ...4 46 345 Conquest Section 4 Electrical System STBD DC Harness Fig 4 44 1...

Page 182: ...4 48 345 Conquest Section 4 Electrical System Windlass Harness Fig 4 46 1...

Page 206: ...5 22 Section 5 Care Maintenance 345 Conquest THIS PAGE INTENTIONALLY LEFT BLANK...