Boston Gear • 800-825-6544

P-3002-BG

9

Note:

The Type “N” and “R” coupling connection

is rigid and does not allow for forgiveness

of parallel or angular misalignment. To

eliminate unnecessary bearing loads, both

shafts must be in near perfect alignment.

8. Loosen the coupling setscrews and attach

coupling to clutch with hex head bolts and flat

washers. Refer to Table 10 for recommended

bolt seating torques. Secure coupling to drive

shaft by tightening the setscrews. (Refer to

Table 8)

IV. Limit Switches

Figure 13 shows a typical use of a limit switch to

detect an overload condition. The switch should be

able to operate within the travel of the limit switch

plate. Upon overload, the limit switch plate will

move to actuate the limit switch and shut down the

drive.

The switch should be wired in parallel with a jog

circuit so that the drive can be indexed for

re-engagement. After the clutch has been

re-engaged, the limit switch will be reset and the

drive can be restarted.

V. General Maintenance

A. Lubrication

The ORC Series, Model F Overload Release

Clutch is prelubricated at the factory and is also

equipped with a grease pack fitting. For optimum

performance and wear resistance it is suggested

that the clutch be lubricated with a Bentone type,

NLGI grade 0 grease. The lubrication schedule

should be in accordance with good operating

practices for the equipment on which the clutch is

mounted. The clutch is also supplied with a grease

relief fitting. When there is enough grease in the

clutch any excess grease will be extruded through

the relief fitting.

B. Annual Inspection

The ORC Series, Model F Overload Release Clutch

is constructed of heavy duty materials. Under

reasonably clean conditions the unit will operate

with a minimum of maintenance. A scheduled

annual inspection of bearings, pawls, rotor, springs,

actuating plate, cam plate and other internal

components is suggested. However, the actual

frequency should be in accordance with good

operating practices for the equipment on which the

clutch is installed.

VI. Repair Instructions

A. General Disassembly

1. All item numbers in parenthesis will refer

to clutch exploded view drawing and parts

identification table.

2. Place the clutch preferable in a three-jaw chuck

with the actuating plate facing up.

3. Remove the return pin nuts (32) from the return

pins. This is accomplished by holding the return

pin steady with a screwdriver while turning the

return pin nut counter-clockwise with a box or

open end wrench.

4. Lift off the actuating plate (26) from the clutch.

5. There are two locking screws (24) located on

the face of the cover which lock down the reset

spring screw (15) and the drive spring screw

(20). Loosen these screws to relive the pressure

on the drive spring screw and reset spring

screw.

6. Turn the reset spring screw (15) counter-

clockwise to relieve the compression on the

reset spring (18).

7. Remove the sealing wax from the drive spring

screw (20) and turn the screw counterclockwise

to relieve the compression on the drive spring

(17).

8. Remove the cam plate (36) from the face of the

cover (8). Be sure not to pry on the outer edge

of the cover as the outer lip may break. (See

Figure 14)

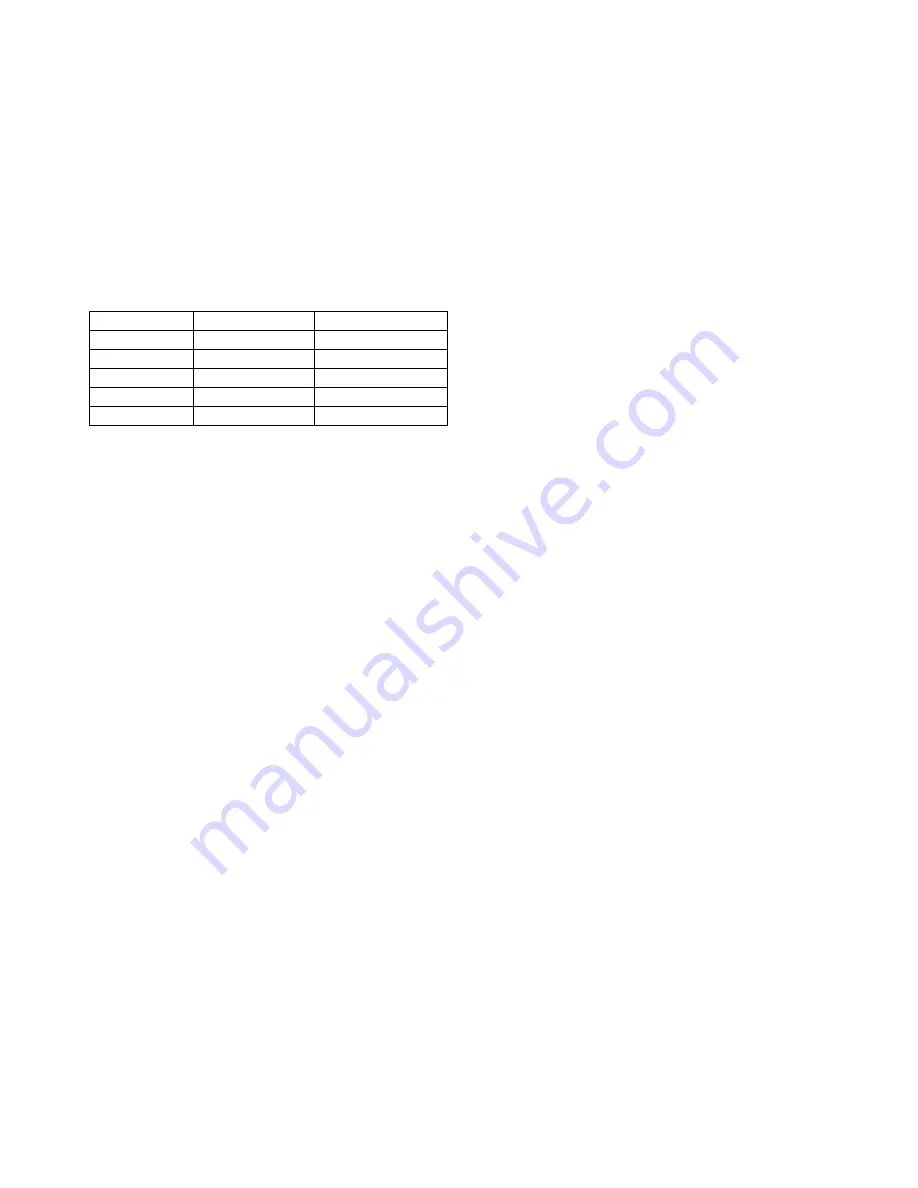

Size

Bolt Size

Seating Torque

1

5/16-18

170 in.lb.

2

3/8-16

300 in.lb.

3

1/2-13

750 in.lb.

4

5/8-11

1,270 in.lb.

5

5/8-11

1,270 in.lb.

Table 10 - Coupling Mounting Bolt Seating

Torques