Regulations and operating conditions

|

37

6 720 807 794 (2013/04)

UNIMAT

5.2.2

Information on flue gas tests pursuant to

BImSchV/TA Luft

First tests or system tests following major

modifications

In the case of systems that have not yet been tested,

have not been tested successfully or have been modified

since testing, we recommend conducting sample tests

at least two months before the planned inspection date.

This procedure should enable any necessary action to be

taken with regard to the combustion equipment in order

to adhere to the specified emissions levels. A Bosch

customer service engineer can be requested to perform

these advance tests; based on the test results, this

engineer will also be able to make suggestions on how

to adhere to the legal levels.

Repeat tests on systems

In the case of systems on which a test has already been

carried out in accordance with BImSchV/TA Luft,

depending on the size and controllability of the

combustion system, it is generally sufficient to make

adjustments either on the day of the official test in the

presence of the testing engineer, or for larger and more

complex systems with several fuel types, one or two

days before this test.

Preparing the system

For the tests to be conducted successfully, it is

necessary to ensure sufficient load reduction, so that

constant operation under steady conditions is possible.

If this cannot be guaranteed, for example due to the

weather in the case of heating systems, we recommend

postponing the test until it can be carried out without

interruption.

Fuels

The fuels to be burned must comply with the notice of

approval and be available in the quality determined for

the system. Since the level of nitrogen in light fuel oil has

a significant effect on the formation of NO

x

, the nitrogen

content of light fuel oil must be known in order to assess

the NO

x

test levels. The fuel oil supplier may be able to

provide this information for the relevant deliveries. To

calculate this value precisely, take an oil sample (1 litre)

from the tank in question at the time of the emissions

test. A test lab can determine the nitrogen content of the

fuel.

Cleaning the boiler

We recommend cleaning the boiler combustion chamber

thoroughly at least one or two days before the test.

Conducting the test

A Bosch customer service engineer should be requested

to conduct the test. If levels exceeding the limits are

registered during the test, it may be possible to modify

the combustion settings so that the test can be

conducted again with success.

Support personnel should be available to assist.

A table and chair should be prepared in the boiler room

for the testing engineer to complete the test reports.

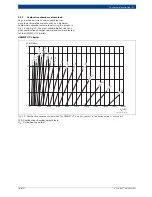

5) CO and NO

X

levels relative to 3 % O

2

content. Half hour average acc. to para. §11(1). Three individual tests (low/medium and full) are

to be carried out in acc. with para. 18(4). With fuel oil EL, the NO

X

levels are relative to a nitrogen content of 140 mg/kg in acc. with

para.11(1).

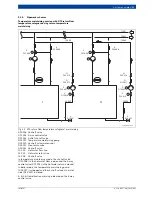

6) The relevant saturated steam operating pressure levels are given in brackets

7) The tests must be carried out by a test body recognised by para. 26 of the BImSchG.