66

|

Fitting

UNIMAT

6 720 807 794 (2013/04)

10

Fitting

10.1

Transport and handling

10.1.1

Delivery method and transport options

The UNIMAT UT-L boiler and UNIMAT UT-L boiler with

integrated heat exchanger are each delivered in a

transport unit.

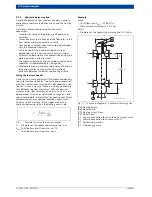

Transport

To transport the boiler block with a crane, only use the

two lifting eyes. These are fitted at the top of the boiler

pressure body, at the front and back.

The use of rollers underneath the base frame to

transport the system at floor level is not permitted.

There is a danger that the base frame will become

warped.

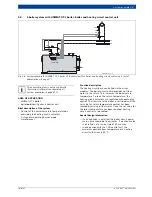

10.1.2

Handling dimensions

For handling the boiler, it is essential to size the

entrance to the installation room slightly larger than the

boiler dimensions. See tab. 29 for the minimum handling

dimensions.

Entrance

UNIMAT UT-L boiler

UNIMAT UT-L boiler

UNIMAT UT-L boiler with flue gas

heat exchanger

Boiler size

Minimum width Minimum height Minimum width Minimum height

[mm]

[mm]

[mm]

[mm]

UT-L 1

–

1400

1850

1500

1865

UT-L 4

UT-L 2

1550

2000

1650

2015

UT-L 10

UT-L 6

1650

2100

1755

2115

UT-L 14

UT-L 8

1750

2200

1855

2215

UT-L 18

UT-L 12

1800

2250

1910

2265

UT-L 24

UT-L 16

1900

2350

1995

2365

UT-L 28

UT-L 20

1950

2400

2060

2415

UT-L 30

UT-L 22

2050

2500

2155

2515

UT-L 34

UT-L 26

2150

2600

2250

2615

UT-L 40

UT-L 32

2350

2800

2435

2800

UT-L 42

UT-L 36

2500

2950

2605

2950

UT-L 46

UT-L 38

2650

3100

2750

3100

UT-L 50

UT-L 44

2800

3300

2905

3250

UT-L 54

UT-L 48

2950

3400

3045

3400

UT-L 58

UT-L 52

3120

3650

3240

3600

UT-L 60

UT-L 56

3450

3950

3555

3900

UT-L 64

UT-L 62

3650

4150

3750

4100

Table 29 Minimum handling dimensions for UNIMAT UT-L boilers; the dimensions specified are recommended values and

may vary from system to system.