11

Installation

Tronic – 6 720 816 255 (2018/06)

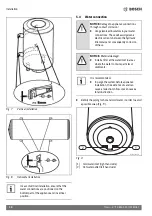

▶ Use the appropriate connection accessories to do the

hydraulic connection to the appliance.

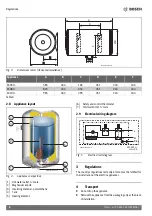

Fig. 10

Water connection

[1] Galvanic insulator

[2] Hot water outlet

[3] Safety valve

[4] Drain connection

[5] Cut off valve

[6] Reduction valve

[7] Non return valve

[8] Connection to the water line

In the case of freezing:

▶ Switch off the appliance.

▶ Purge the appliance (

chapter 6.3).

Safety valve

5.5

Electrical connections

All adjusting devices, verification and safety mechanisms were

submitted to a rigorous test in factory and are ready to work.

▶ Connect the appliance via a socket with earth connection.

5.6

Start-up

▶ Verify that the appliance has been correctly installed and

assembled.

▶ Open the water inlet valves.

▶ Open all the hot water taps in order to ensure all the air is

purged from the piping.

▶ Control the tightness of all the connections and ensure that

the appliance fills to its full capacity.

▶ Connect the appliance to the electric current.

▶ Inform the customer of any user information of the

appliance and handling.

In order to avoid problems caused by sudden

pressure changes, we recommend the

installation of a non return valve at the

appliance (Fig. 10, [7]).

DANGER:

▶ Install a safety valve at the water inlet of

the appliance (Fig. 10).

NOTICE:

NEVER OBSTRUCT THE PURGE OUTLET OF

THE SAFETY VALVE.

Never install any accessory between the

safety valve and the cold-water inlet (right

hands side) of the appliance.

6720643873-05.1V

3

4

5

6

7

8

2

1

1

If the pressure at the cold water inlet is

superior to that of 80% of the maximum

pressure of the appliance at, ie: 6,4 bar:

▶ Install a reducing valve (Fig. 10).

The safety valve will trigger every time the

water pressure in the appliance exceeds 8

bar (

0,5 bar). A facility for draining the

expelled water must be provided.

DANGER:

By electrical discharge!

▶ Before working on the electrical

components, firstly cut the power, (fuse,

circuit breaker or other).

CAUTION:

Electrical protection!

▶ The appliance should dispose of an

independent connection to the DB board

(electric board), protected by a 30 mA

differential circuit breaker and earthing.

The electrical connection must be realized in

accordance with the current country laws

regarding electrical installations.