English |

19

Bosch Power Tools

2 609 006 763 | (17.1.13)

Do not position your body in line with and behind the ro-

tating wheel.

When the wheel, at the point of operation, is

moving away from your body, the possible kickback may

propel the spinning wheel and the power tool directly at you.

When wheel is binding or when interrupting a cut for

any reason, switch off the power tool and hold the pow-

er tool motionless until the wheel comes to a complete

stop. Never attempt to remove the cut-off wheel from

the cut while the wheel is in motion otherwise kickback

may occur.

Investigate and take corrective action to elimi-

nate the cause of wheel binding.

Do not restart the cutting operation in the workpiece.

Let the wheel reach full speed and carefully re-enter

the cut.

The wheel may bind, walk up or kickback if the

power tool is restarted in the workpiece.

Support panels or any oversized workpiece to minimize

the risk of wheel pinching and kickback.

Large work-

pieces tend to sag under their own weight. Supports must

be placed under the workpiece near the line of cut and near

the edge of the workpiece on both sides of the wheel.

Use extra caution when making a “pocket cut” into ex-

isting walls or other blind areas.

The protruding wheel

may cut gas or water pipes, electrical wiring or objects that

can cause kickback.

Safety warnings specific for sanding operations

Do not use excessively oversized sanding disc paper.

Follow manufacturers recommendations, when select-

ing sanding paper.

Larger sanding paper extending be-

yond the sanding pad presents a laceration hazard and

may cause snagging, tearing of the disc, or kickback.

Safety warnings specific for wire brushing operations

Be aware that wire bristles are thrown by the brush

even during ordinary operation. Do not overstress the

wires by applying excessive load to the brush.

The wire

bristles can easily penetrate light clothing and/or skin.

If the use of a guard is recommended for wire brushing,

do not allow any interference of the wire wheel or

brush with the guard.

Wire wheel or brush may expand in

diameter due to work load and centrifugal forces.

Additional safety warnings

Wear safety goggles.

Use suitable detectors to determine if utility lines are

hidden in the work area or call the local utility company

for assistance.

Contact with electric lines can lead to fire

and electric shock. Damaging a gas line can lead to explo-

sion. Penetrating a water line causes property damage or

may cause an electric shock.

Release the On/Off switch and set it to the off position

when the power supply is interrupted, e. g., in case of a

power failure or when the mains plug is pulled.

This pre-

vents uncontrolled restarting.

Do not touch grinding and cutting discs before they

have cooled down.

The discs can become very hot while

working.

Secure the workpiece.

A workpiece clamped with clamp-

ing devices or in a vice is held more secure than by hand.

Products sold in GB only

: Your product is fitted with an

BS 1363/A approved electric plug with internal fuse (ASTA

approved to BS 1362).

If the plug is not suitable for your socket outlets, it should be

cut off and an appropriate plug fitted in its place by an author-

ised customer service agent. The replacement plug should

have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains sock-

et elsewhere.

Products sold in AUS and NZ only

: Use a residual current de-

vice (RCD) with a rated residual current of 30 mA or less.

Product Description and Specifica-

tions

Read all safety warnings and all instruc-

tions.

Failure to follow the warnings and in-

structions may result in electric shock, fire

and/or serious injury.

Intended Use

The machine is intended for cutting, roughing and brushing of

metal and stone materials without the use of water.

For cutting with bonded abrasives, a special cutting guide (ac-

cessory) must be used.

When cutting in stone, provide for sufficient dust extraction.

With approved sanding tools, the machine can be used for

sanding with sanding discs.

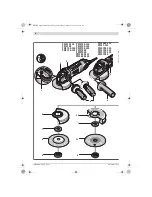

Product Features

The numbering of the product features refers to the illustra-

tion of the machine on the graphics page.

1

Release lever for protection guard

2

Spindle lock button

3

On/Off switch

4

Auxiliary handle (insulated gripping surface)

5

Grinder spindle

6

Protection guard for grinding

7

Mounting flange

8

Grinding wheel*

9

Clamping nut

10

Protection guard for cutting*

11

Cutting disc*

12

Hand guard*

13

Rubber sanding plate*

14

Sanding sheet*

15

Round nut*

16

Cup brush*

OBJ_BUCH-1824-001.book Page 19 Thursday, January 17, 2013 10:33 AM