English |

17

Bosch Power Tools

2 609 006 763 | (17.1.13)

When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use.

Use of a cord suitable

for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoid-

able, use a residual current device (RCD) protected

supply.

Use of an RCD reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication.

A moment of inattention while op-

erating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Car-

rying power tools with your finger on the switch or energis-

ing power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning

the power tool on.

A wrench or a key left attached to a ro-

tating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at

all times.

This enables better control of the power tool in

unexpected situations.

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are con-

nected and properly used.

Use of dust collection can re-

duce dust-related hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool

for your application.

The correct power tool will do the

job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it

on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool.

Power

tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean.

Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

Use the power tool, accessories and tool bits etc. in ac-

cordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair per-

son using only identical replacement parts.

This will en-

sure that the safety of the power tool is maintained.

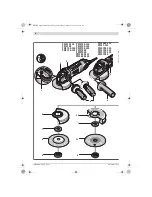

Safety Warnings for Angle Grinder

Safety Warnings common for Grinding, Sanding,

Wire Brushing or Abrasive Cutting Off Operations

This power tool is intended to function as a grinder,

sander, wire brush or cut-off tool. Read all safety warn-

ings, instructions, illustrations and specifications pro-

vided with this power tool.

Failure to follow all instruc-

tions listed below may result in electric shock, fire and/or

serious injury.

Operations such as polishing are not recommended to

be performed with this power tool.

Operations for which

the power tool was not designed may create a hazard and

cause personal injury.

Do not use accessories which are not specifically de-

signed and recommended by the tool manufacturer.

Just because the accessory can be attached to your power

tool, it does not assure safe operation.

The rated speed of the accessory must be at least equal

to the maximum speed marked on the power tool.

Ac-

cessories running faster than their rated speed can break

and fly apart.

The outside diameter and the thickness of your acces-

sory must be within the capacity rating of your power

tool.

Incorrectly sized accessories cannot be adequately

guarded or controlled.

Threaded mounting of accessories must match the

grinder spindle thread. For accessories mounted by

flanges, the arbour hole of the accessory must fit the

locating diameter of the flange.

Accessories that do not

match the mounting hardware of the power tool will run out

of balance, vibrate excessively and may cause loss of con-

trol.

Do not use a damaged accessory. Before each use in-

spect the accessory such as abrasive wheels for chips

and cracks, backing pad for cracks, tear or excess

wear, wire brush for loose or cracked wires. If power

tool or accessory is dropped, inspect for damage or in-

stall an undamaged accessory. After inspecting and in-

stalling an accessory, position yourself and bystanders

away from the plane of the rotating accessory and run

the power tool at maximum no-load speed for one min-

ute.

Damaged accessories will normally break apart during

this test time.

OBJ_BUCH-1824-001.book Page 17 Thursday, January 17, 2013 10:33 AM