English |

17

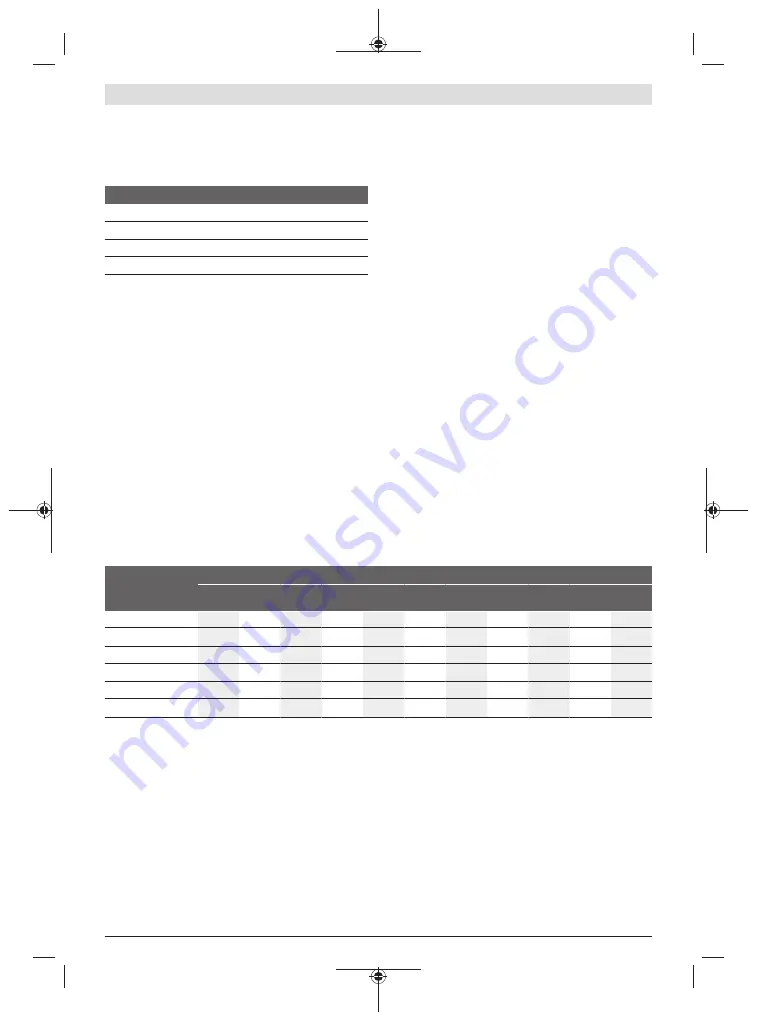

Battery charge indicator

When the on/off switch

(10)

is pressed in halfway or com-

pletely, the battery charge-control indicator

(11)

indicates

the charge condition of the battery for several seconds. The

indicator consists of three green LEDs.

LED

Capacity

Continuous lighting 3 x green

≥2/3

Continuous lighting 2 x green

≥1/3

Continuous lighting 1 x green

<1/3

Flashing light 1 x green

Reserve

Temperature-dependent overload protection

In normal conditions of use, the power tool cannot be over-

loaded. If the power tool is overloaded or the permitted bat-

tery temperature is exceeded, the electronics of the power

tool will switch off until the temperature returns to within the

optimum operating temperature range.

Practical advice

The torque depends on the impact duration. The maximum

achieved torque results from the sum of all individual

torques achieved through impact. Maximum torque is

achieved after an impact duration of 6–10 seconds. After

this duration, the tightening torque increases only minimally.

The impact duration is to be determined for each required

tightening torque. The tightening torque actually achieved

should always be checked with a torque wrench.

Screw applications with hard, spring-loaded or soft seats

When the achieved torques in an impact series are measured

during a test and transferred into a diagram, the result is the

curve of a torque characteristic. The height of the curve cor-

responds with the maximum reachable torque, and the

steepness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/bolted

together

– Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

– A

hard seat

is a metal-to-metal screw application which

uses washers. After a relatively short impact duration, the

maximum torque is reached (steep characteristic curve).

Unnecessary long impact duration only causes damage to

the machine.

– A

spring-loaded seat

is also a metal-to-metal screw ap-

plication but uses spring washers, disc springs, studs or

screws/nuts with conical seats. It is also called a spring-

loaded seat when extensions are used.

– A

soft seat

is a screw application of e.g. metal on wood or

a screw application that uses lead washers or fibre wash-

ers as backing.

For a spring-loaded seat as well as for a soft seat, the max-

imum tightening torque is lower than for a hard seat. Also, a

clearly longer impact duration is required.

Guide values for maximum screw tightening torques

Figures given in Nm; calculated from the tensional cross-section; utilization of the yield point: 90% (with friction coefficient

µ

total

= 0.12). As a control measure, always check the tightening torque with a torque wrench.

Property Classes

according to

DIN 267

Standard Screws/Bolts

High-strength Bolts

3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

M6

2.71

3.61

4.52

4.8

5.42

6.02

7.22

8.13

9.7

13.6

16.2

M8

6.57

8.7

11

11.6

13.1

14.6

17.5

19.7

23

33

39

M10

13

17.5

22

23

26

29

35

39

47

65

78

M12

22.6

30

37.6

40

45

50

60

67

80

113

135

M14

36

48

60

65

72

79

95

107

130

180

215

M16

55

73

92

98

110

122

147

165

196

275

330

Tips

Before screwing larger, longer screws into hard materials, it

is advisable to pre-drill a pilot hole with the core diameter of

the thread to approx. 2/3 of the screw length.

Note:

Ensure that no metal particles enter the power tool.

Recommendations for optimal handling of the battery

Protect the battery against moisture and water.

Only store the battery within a temperature range of -20 to

50 °C. Do not leave the battery in your car in the summer, for

example.

A significantly reduced operating time after charging indic-

ates that the battery has deteriorated and must be replaced.

Follow the instructions on correct disposal.

Occasionally clean the ventilation slots and the terminals on

the battery using a soft brush that is clean and dry.

Belt clip (see figure

E)

You can use the belt clip

(17)

to hang the power tool on a

belt, for example. You then have both hands free and the

power tool is always at hand.

Coloured clip (see figure

F)

You can use the coloured clip

(18)

to individually identify the

power tool.

Bosch Power Tools

1 609 92A 7X1 | (15.07.2022)

Summary of Contents for Professional GDR 12V-110

Page 3: ... 3 1 2 3 4 5 6 7 8 12 9 10 11 GDR 12V 110 Bosch Power Tools 1 609 92A 7X1 15 07 2022 ...

Page 4: ...4 GDR GDS 8 7 13 15 14 15 1 16 9 9 1 2 A B C D 1 609 92A 7X1 15 07 2022 Bosch Power Tools ...

Page 5: ... 5 17 18 E F Bosch Power Tools 1 609 92A 7X1 15 07 2022 ...

Page 215: ... 215 1 4 6 35 mm 1 2 12 7 mm Bosch Power Tools 1 609 92A 7X1 15 07 2022 ...

Page 216: ...216 1 600 A00 1RP 1 600 A00 4BH L BOXX 102 1 609 92A 7X1 15 07 2022 Bosch Power Tools ...

Page 220: ...IV 1 609 92A 7X1 15 07 2022 Bosch Power Tools ...