10.7

Bearing and shaft load

10.7.1

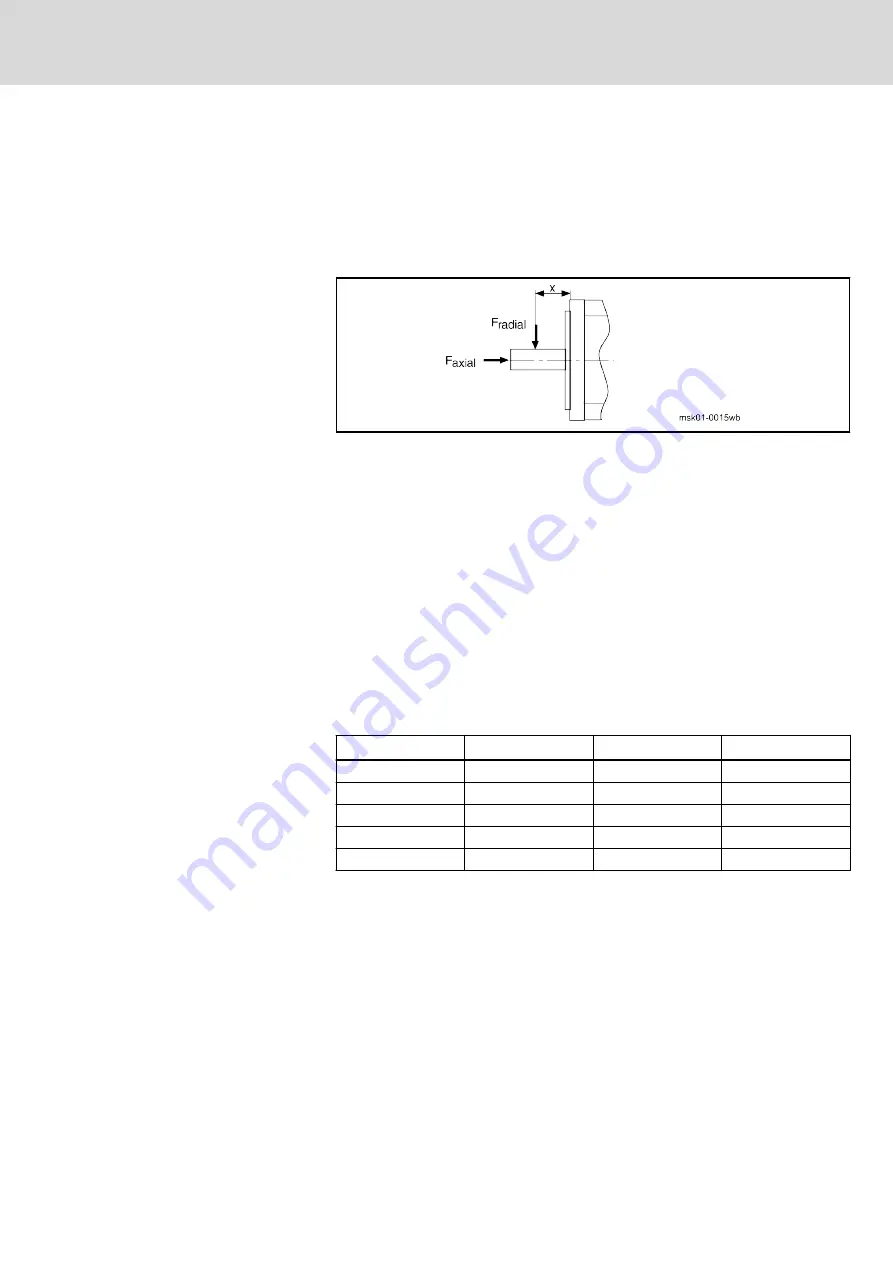

Radial load, axial load

During operation, radial and axial forces act on the motor shaft and the motor

bearings. The design of the machine, the selected motor type and the shaft-

side mounting of drive elements must be coordinated to ensure that the

specified load limits are not exceeded.

x

Point of application of force

Fig. 10-6:

Example diagram of shaft load

Maximum allowed radial force

The maximum permissible radial force F

radial_max

depends on the following

factors

●

Shaft breaking load

●

Force action point x

●

Shaft plain or with keyway

Permissible radial force

The permissible radial load F

radial

depends on the following factors

●

Arithmetically averaged speed (n

average

)

●

Force action point x

●

Bearing service life

Permissible axial force

The maximum permissible axial force F

axial

for the individual motor sizes is

shown in the following table.

Motor

F

axial

[N]

Motor

F

axial

[N]

MSK030

0

MSK070

60

MSK04x

30

MSK071

60

MSK050

40

MSK076

60

MSK060

40

MSK100

80

MSK061

40

MSK101

80

Tab. 10-7:

Maximum permissible axial force F

axial

Axial forces are permissible without restriction up to the specified values.

Larger axial forces may be possible after detailed examination by your

Rexroth sales partner. Specify the following information for the valuation:

●

Axial and radial force with force application point

●

Installation position (horizontal, vertical with the shaft end pointing to the

top or bottom)

●

Average speed

Average speed

Run-up and braking times can be omitted from the calculation if the time dur‐

ing which the drive is operated at constant speed is considerably longer than

the acceleration and braking times. In the exact calculation of the average

speed according to the following pattern, acceleration and braking times are

taken into account.

DOK-MOTOR*-MSK*EXGIIK3-PR09-EN-P

Bosch Rexroth AG

125/175

Synchronous Servomotors MSK For Potentially Explosive Areas

Operating conditions and application notes