Summary of Contents for L 309 Series

Page 1: ...Power Supply Module Technical Information L 309 150 L 309 250 104 Edition ...

Page 3: ......

Page 5: ...Flexible Automation Type L 309 Power Supply Module 1070 078 131 104 00 05 GB ...

Page 15: ...Flexible Automation Type L 309 Power Supply Module Structure 2 1070 078 131 104 00 05 GB ...

Page 27: ...Maintenance Type L 309 Power Supply Module 14 1070 078 131 104 00 05 GB ...

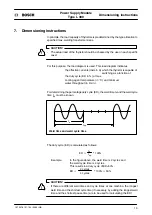

Page 31: ...Dimensioning instructions Type L 309 Power Supply Module 18 1070 078 131 104 00 05 GB ...

Page 33: ...Fault messages Type L 309 Power Supply Module 20 1070 078 131 104 00 05 GB ...

Page 36: ...A 1 1070 078 131 104 00 05 GB 1070 078 131 104 00 05 GB TI WS AT VWS Printed in Germany ...