12

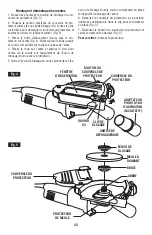

Use the adjustable depth stop to obtain the

desired depth of mortar removal. The tuck-

pointer is held with the guard window facing

upward so that the user can easily see the

joint during operation.

Allow the tool to reach full speed before apply-

ing it to the workpiece surface.

Hold the tool with both hands and apply the

abrasive wheel to the mortar surface.

Diamond Wheels

Do not use water when

cutting with this tool.

The tool is not designed for water and electric

shock may occur.

If this tuckpointer is being

used as a small abrasive

cutoff machine, the tool is only approved for

cutting or scoring masonry products like:

Concrete, cinder blocks, bricks, and stone.

Use Type 41/1A dry diamond wheels for cut-

ting masonry and concrete. Dry diamond

wheels stay cooler, clog less and last longer.

1. Before running a cut-off machine, inspect

the cutting wheel for chips or cracks. Re-

place bad wheels immediately. New wheels

should be run in at no load for at least a

minute in the direction away from the pres-

ence of other people. Imperfect wheels will

normally break apart during this time.

2. An abrasive cut-off machine must NEVER

be operated without the attached guard se-

curely in place. The guard should be rotated

into the position where maximum protection

is provided for the operator from sparks and

wheel periphery.

3. Proper apparel for operating the tool in-

cludes eye protection, leather gloves and

dust mask.

4. With the tool in the “OFF” position, become

familiar with handling the tool. Control the

head of the tool with the side handle. Con-

trol the cutting edge of the wheel with the

switch handle. Always use both hands when

operating the tool.

5. Never drop the tool. Set the tool down gen-

tly, but never on the wheel.

6. CUTTING CONCRETE will throw large

amounts of dust into the surrounding area.

Protective dust masks are required for

breathing protection for the operator and

other nearby workers.

7. It is not recommended to use this tool over-

head or in any position that would not allow

proper control. Ladders are not considered

solid support structures.

8. Avoid overloading tool. Do not allow the

wheel to bind or stall. Many cuts, espe-

cially into solid concrete, require successive

passes. Do not expose any more abrasive

wheel than necessary to cut with normal

amount of pressure applied to tool. Begin

cutting from the edge of the material, only

plunging to a depth of one diamond wheel

segment. Cutting too deeply at one time

does not allow dust to clear fully and erodes

/thins body of wheel. Do not force the tool;

load it normally. Depending on material

hardness and density, make successively

deeper passes until cut is complete.

Constant Response Circuitry

The internal electronic feedback system

provides a “soft start”, which will reduce the

stresses that occur from a high torque start.

The system also helps to keep the no load

speed virtually constant between no-load and

load conditions.

Overload Protection

Your tool is equipped with overload protection

to protect the motor. If the tool stops during

operation TURN OFF SWITCH IMMEDIATE-

LY and allow the motor to cool for about 30

seconds by running at no-load. If the overload

protection stops the tool repeatedly, exces-

sive force is causing the tool to overload. Don’t

press so hard and let the tool do the work.

Summary of Contents for GWS13-52TG

Page 39: ...39 Notes Remarques Notas ...