36

| English

u

Always secure a grinding/cutting disc using only the

quick-clamping nut (21)

supplied

.

Press the spindle lock but-

ton

(3)

to lock the grinding

spindle. To tighten the

quick-clamping nut

(21)

,

fold up the bar and turn the

quick-clamping nut firmly

clockwise. Then fold down

the bar to secure the quick-

clamping nut.

It is not suf-

ficient to tighten the disc

along the edge.

Quick-clamping nuts

(21)

that are properly secured

and not damaged can be re-

moved by hand. To do this,

fold up the bar and turn the

quick-clamping nut firmly

anticlockwise. If the quick-

clamping nut is stuck, do

not attempt to loosen it with

a tool – always use a two-

pin spanner.

After fitting the mounting

flange and the grinding/cut-

ting disc, the free thread

length of the grinding

spindle must be

at least

4 mm

.

Ensure that the abrasive

tool is firmly seated, so that

it does not twist away from the spindle in the runout of the

power tool.

A plastic part (O-ring) is fitted around the cent-

ring collar in the mounting flange

(17)

.

If the

O-ring is missing or damaged,

the mounting

flange

(17)

must be replaced before operation

can resume.

u

After fitting the abrasive tool, check that the abrasive

tool is fitted correctly and can turn freely before

switching on the power tool. Make sure that the abras-

ive tool does not brush against the protective guard or

other parts.

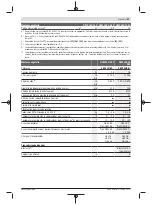

Approved abrasive tools

You can use all the abrasive tools mentioned in these operat-

ing instructions.

The permissible speed [min

-1

] or the circumferential speed

[m/s] of the abrasive tools used must at least match the val-

ues given in the table.

It is therefore important to observe the permissible

rota-

tional/circumferential speed

on the label of the abrasive

tool.

Max. [mm]

[mm]

[°]

D

b

s

d

α

[min

-1

] [m/s]

125

150

7.2

7.2

–

–

22.2

22.2

–

–

11,000

8500

80

80

125

150

4.2

4.2

–

–

22.2

22.2

–

–

11,000

8500

80

80

125

150

–

–

–

–

–

–

–

–

11,000

8500

80

80

75

30

–

M 14

–

11,000

80

125

125

150

150

24

19

24

19

–

–

–

–

M 14

22.2

M 14

22.2

–

–

–

–

11,000

11,000

8500

8500

80

80

80

80

125

–

–

M 14

–

11,000

80

83

–

–

M 14

–

11,000

80

α

s

125

150

6

6

10

10

22.2

22.2

> 0

> 0

11,000

8500

80

80

125

21

–

22.2

–

11,000

80

Rotating the machine head (see figure F)

u

Remove the battery from the power tool before carry-

ing out work on the power tool (e.g. maintenance,

changing tool, etc.). The battery should also be re-

moved for transport and storage.

There is risk of injury

from unintentionally pressing the on/off switch.

The machine head can be rotated in 90° increments. In this

way, the on/off switch can be brought into a more favourable

handling position for particular applications, e.g. for left-

handed tool users.

Completely unscrew the four screws (

➊

). Rotate the ma-

chine head carefully,

without removing it from the hous-

ing

, into the new position (

➋

). Screw in and retighten the

four screws (

➌

).

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

1 609 92A 6WP | (08.06.2022)

Bosch Power Tools

Summary of Contents for GWS Professional 18V-15 C

Page 3: ... 3 A B C D 16 14 16 14 16 14 14 16 Bosch Power Tools 1 609 92A 6WP 08 06 2022 ...

Page 6: ...6 0 mm 4x 4x F 1 609 92A 6WP 08 06 2022 Bosch Power Tools ...

Page 552: ...552 standard Inox standard Metal 1 609 92A 6WP 08 06 2022 Bosch Power Tools ...

Page 556: ...556 1 609 92A 6WP 08 06 2022 Bosch Power Tools ...

Page 560: ...IV 1 609 92A 6WP 08 06 2022 Bosch Power Tools ...