22

| English

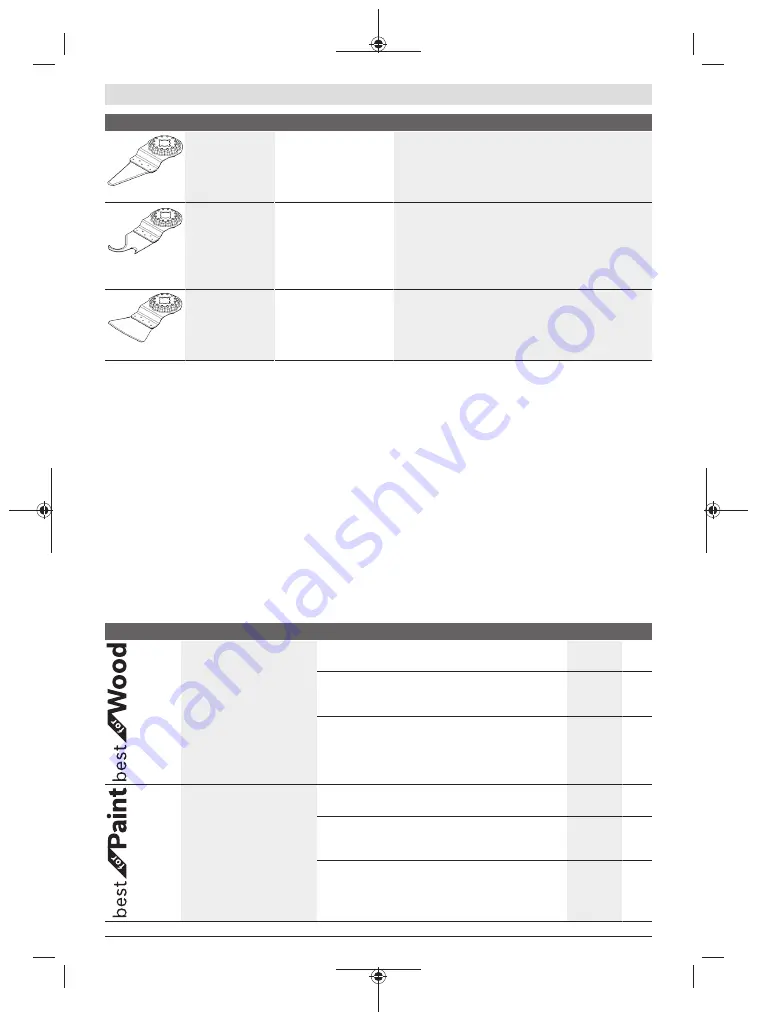

Application tool

Material

Application

AIZ 28 SC

Starlock

28 × 40 mm HCS

universal joint cut-

ter

Expansion joints, window

putty, insulation materials

(rock wool)

Cutting soft materials;

example: Cutting silicone expansion joints or window

putty

ASZ 32 SC

Starlock

24 mm-wide HCS

pull cutting edge,

11 mm-wide HCS

push cutting edge

Roofing felt, carpets, arti-

ficial turf, cardboard, PVC

flooring

Quick and precise cutting of soft material and flexible, ab-

rasive materials;

Example: Cutting carpets, cardboard, PVC flooring, re-

cesses in roofing felt

ATZ 52 SC

Starlock

52 mm scraper, ri-

gid

Carpets, mortar, con-

crete, tile adhesive

Scraping on a hard substrate;

Example: Removing mortar, tile adhesive and concrete

and carpet adhesive residues;

available as flexible scraper ATZ 52 SFC (soft carpet ad-

hesive/paint residues)

Fitting/changing the application tool

Remove the application tool if one has already been fitted.

To do so, open the SDS lever

(5)

all the way. The application

tool/accessory will be ejected.

Position the required application tool (e.g. plunge cut saw

blade

(11)

) on the tool holder

(6)

so that the depressed

centre is facing downwards (see figure on the graphics page,

text on the application tool should be legible from above).

When doing so, place the application tool/accessory in a po-

sition which is convenient for the job at hand. Twelve posi-

tions offset by 30° are possible for this.

Press the application tool in the required position firmly onto

the clamping jaws of the tool holder until it locks automatic-

ally.

u

Check that the application tool is seated securely.

Ap-

plication tools that are attached incorrectly or are not se-

curely fixed in place may come loose during operation,

thereby putting you at risk.

Mounting and adjusting the depth stop

The depth stop

(10)

can be used when working with seg-

ment and plunge cut saw blades.

Remove the application tool if one has already been fitted.

Slide the depth stop

(10)

into the required working position

over the tool holder

(6)

and onto the collar of the power tool

as far as it will go. Allow the depth stop to engage. Twelve

positions offset by 30° are possible for this.

Set the depth you wish to work at. Push the clamping lever

(9)

of the depth stop shut to fix the depth stop in position.

Selecting a sanding sheet

Different sanding sheets are available, depending on the material you are working with and the required surface removal rate:

Sanding sheet Material

Application

Grit

– All wood and wood-based

materials (e.g. hardwood,

softwood, chipboard, con-

struction boards)

– Metal materials

For pre-sanding, e.g. of rough and uneven beams and

boards

Coarse

40

60

For surface sanding and levelling of slight irregularities

Medium

80

100

120

For finish-sanding and fine sanding of wood

Fine

180

240

320

400

– Paint

– Varnish

– Filler

– Bodyfiller

For sanding down paint

Coarse

40

60

For sanding undercoats (e.g. removing brushstrokes,

paint drips and paint runs)

Medium

80

100

120

For final sanding of primers prior to painting

Fine

180

240

320

400

1 609 92A 5NM | (04.06.2020)

Bosch Power Tools