13

EP Series

8733922168

Revised 12-13 Subject to change without prior notice

Hot Gas Reheat

Sequence of Operation - On/Off Control

The sequence of operation in the cooling and

heating mode is the same as a regular heat pump.

In the reheat mode on a call from the humidistat the

reheat relay coil is energized through the “H” circuit.

The blower relay, reversing valve and compressor

contactor are energized through the contacts of the

reheat relay. See typical wiring diagrams at the end

of the manual. The cooling relay remains de-

energized enabling the reheat solenoid (Note: The

reheat mode always operates in the cooling mode.)

Should the temperature in the space increase above

set point the compressor terminal Y is energized

which will de-energize the reheat valve putting the

unit into the straight cooling mode. A call for cooling

or heating will always take precedence over hot gas

reheat.

Hot Gas Reheat Controllers

There are several ways to control heat pumps with

hot gas reheat. You should choose the means that

best suits your specific application. See typical

wiring diagrams and the end of the manual for

some possible control sequences. Most heat pump

compatible thermostats in conjunction with a

humidistat are acceptable for use, (Note: “O”

output for reversing valve energized in cooling

mode is required.) Combination thermostats/

humidistat are also available.

Special Considerations

Some applications require special consideration to

maximize the performance of the hot gas reheat

function:

• Low Temperature Well Water

• Indoor Pool Dehumidifying During Winter Months

Consult the factory for special application

considerations.

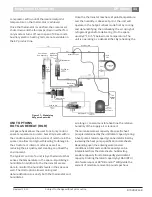

Refrigerant Flow Path

A hot gas reheat valve and a reheat coil are included in the

refrigerant circuit. The refrigerant circuit in the cooling

and heating mode is identical to a standard heat pump.

In the reheat mode the compressor discharge gas is

diverted through the reheat valve to the reheat coil

which is located downstream of the cooling coil. The

superheated refrigerant gas reheats the air leaving the

cooling coil. The hot refrigerant gas then passes

though the water to refrigerant coil where it is

condensed to a liquid. From this point the rest of the

cooling cycle is completed as in a regular heat pump.

There are two check valves to prevent refrigerant flow

into the reheat coil during standard cooling/heating

cycles. A small copper bleeder line is connected to the

outlet line of the reheat coil and between the

expansion valve outlet and distributor to the air coil.

This line is necessary to let any liquid/oil that may have

migrated to the reheat coil during reheat to escape

during standard cooling/heating modes. (See Figure 5)

Figure #8 – Modulating Hot Gas Reheat Valve

Handle, set screw

& flow indicator

at 0 VDC position

Self Adapt–OFF

CW Rotation

Direct Acting Feedback

Rotate CW

Rotate CW

Scale Position Indicator on Handle

Drive Pin Location

To Reheat Coil

To Condenser/

Reversing Valve

Weld

From Compressor