30

MACHINE PREPARATION

3.

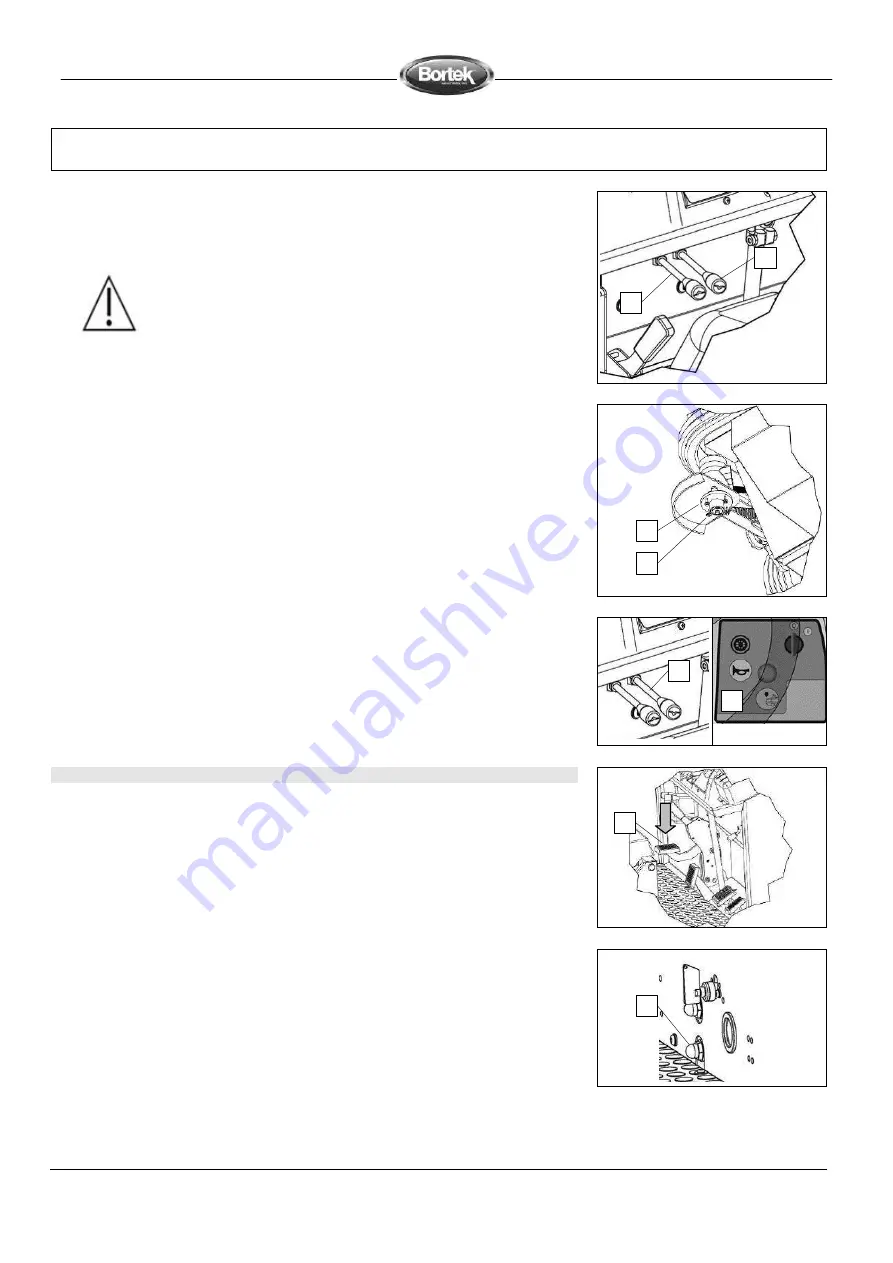

Turn the main machine switch to the “ON” position, turn it by a quarter rotation to the right

4.

Make sure that the hopper hatch is closed, if this is not the case not pull the lever (3) upwards

5.

Raise the hopper to its maximum height, pulling the lever (4) up, engage the safety catches supplied

with the machine

WARNING!

The safety catches, supplied with the machine, should be inserted into

the shafts of the pistons controlling the raising of the hopper.

6.

Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

7.

With the proper equipment, remove the screws (5) in the side brush hub

8.

Insert the side brush into the brush hub (6)

9.

With the proper equipment, fix the side brush to the brush hub (6) using the screws (5)

10.

Remove the safety catches

11.

Turn the main machine switch to the “ON” position, turn it by a quarter rotation to the right

12.

Lower the hopper until it is in the work position, pulling the lever (4) downwards, while at the same

time pushing the dead man's button (7) on the instrument panel

36.

CHECKING THE HYDRAULIC SYSTEM OIL

This machine is equipped with a hydraulic system. To ensure optimum machine performance, check the oil

level in the following way:

1.

Block the machine by engaging the parking brake, pressing the pedal (1) down

2.

Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

3.

Check the oil is not below the minimum level, as seen on the transparent cap (2). If necessary, add

more oil by following the instructions in the “MAINTAINING THE HYDRAULIC OIL LEVEL” chapter.

4

3

1

2

4

7

6

5