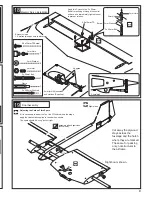

7

14

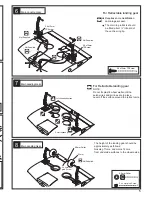

Rudder Servo installation

Cut away covering film.

8

2.6 x12mm TP Screw

2.6 x12mm TP Screw

Assemble left and right sides

the same way.

500mm. servo extension wires to rudder

servos in both booms. Alos 700mm.

extension wires to Elevator Servo in

Left hand boom only .(not supplied)

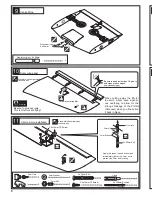

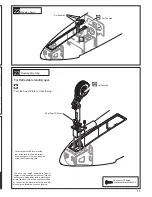

10

21

20

In order to save weight at the tail end, you

can use “Midi” servos for the rudders. If you

do this make up 6mm (1/4”) liteply plates to

raise the smaller servos and reduce the

standard spacing of the servo mountings

supplied. Remember to allow for the shrink-

age of the covering when cutting away for

the servo mounts.

Tail Assembly

3 x 20mm Bolt

4

3 x 20mm Bolt

3 x 20mm Bolt

Decrease size of top

exit hole after wires

are through to prevent

the connector falling

inside the fin.

Self-adhesive

4

Self-adhesive

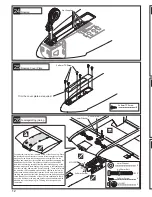

13

12

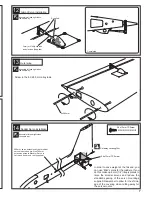

Aileron Servo installation

Completed

Outer wing

Assemble left and right sides

the same way.

Assemble left and right sides

the same way.

2.5mm Hex Wrench

Lock

3 x 10mm Bolt

4

3x10mm Bolt

3x10mm Bolt

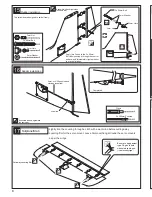

Wing Top

Wing Locking

3mm.(or 4/40)pushrods

and clevises (Supplied)

Supplied

8x285mm

Screw in the 8 X 285 mm alloy rods.