Instruction Manual for F1300/1600 Mud Pump

42

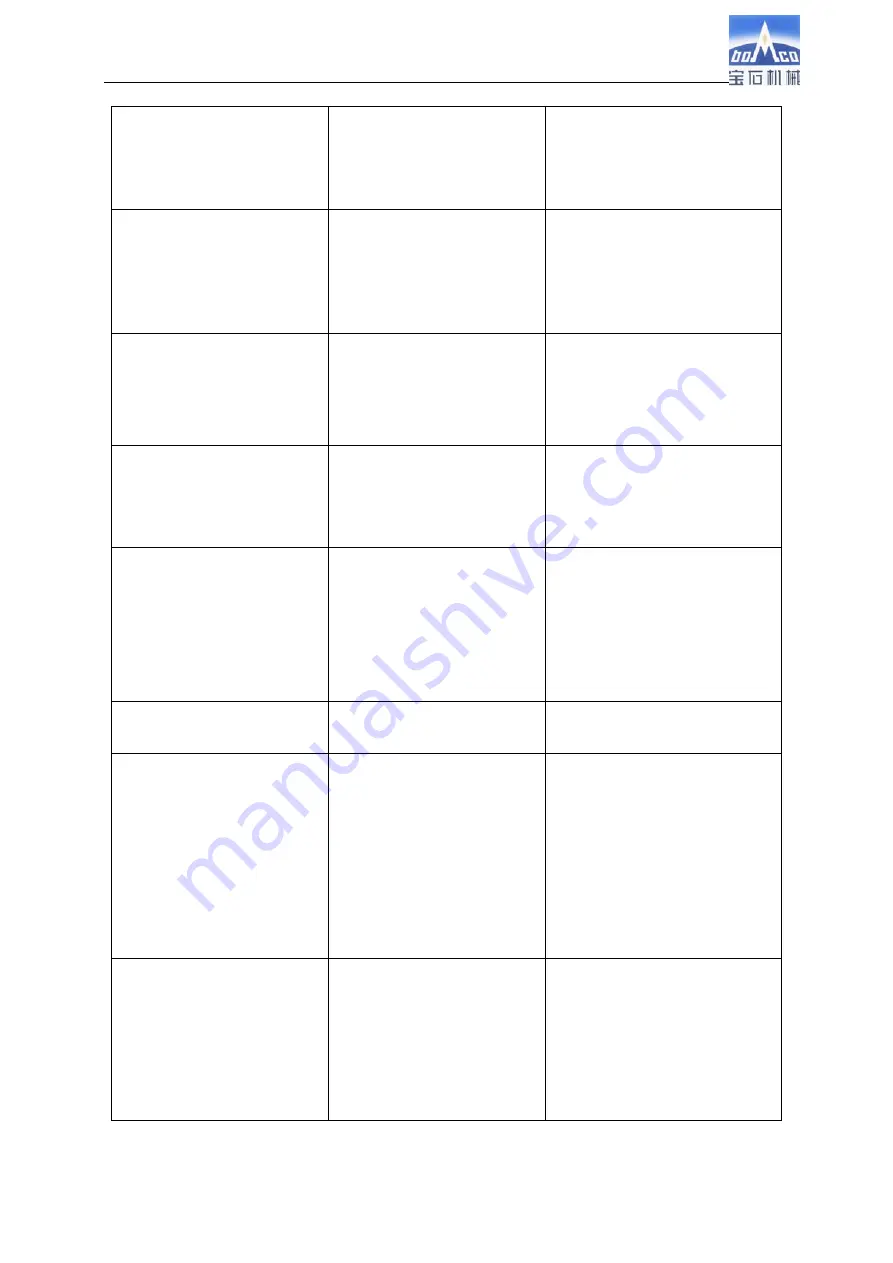

become low and the

discharge reduces or no mud

discharged.

sealed off and the air gets

into the pump.

2. The suction filter screen is

plugged.

charging piping or change the

gasket.

2. Stop the pump and clean the

suction filter screen.

2. Uneven discharge. The

pressure gauge fluctuates.

The charging piping has

abnormal noise.

1. A piston or a valve is worn

out or damaged.

2. There is air in the pump

cylinder.

1. Change the damaged piston

and check the valve to find if it’s

damaged or plugged.

2. Check if the charging piping

and valve cap are sealed off.

3. There is severe knock in

the liner.

1. The piston nuts are loose.

2. The liner cover is loose.

3. The suction is not good

caused water dash.

1. Tighten the piston nuts.

2. Tighten the liner cover.

3. Check the reason of improper

suction.

4. The mud leakage from the

alarm bore of valve cap,

cylinder and liner seal.

1. The valve cap and the

cylinder cover are not

tightened.

2. The seal ring is damaged.

1. Tighten the valve cap and the

cylinder cover.

2. Change the seal ring.

5. The discharge pulsation

dampener can’t be charged or

it leaks soon after charging.

1. The charging connector is

plugged.

2. The bladder of the

pulsation dampener is broken.

3. The needle valve is not

sealed.

1. Clean the connector.

2. Change the bladder.

3. Repair or change the needle

valve.

6. The diesel is overloaded.

The discharge filter drum is

plugged.

Remove the filter screen and

clean it.

7. Abnormal temperature on

running friction parts like

power end, crosshead etc.

1. The oil pipe or oil port is

plugged.

2. The lubricating oil is too

dirty or deteriorated.

3. The rolling bearing is worn

or damaged.

4. The lubricating oil is too

much or too little.

1. Clean the oil pipe or oil port.

2. Change new oil.

3. Repair or change bearing.

4. Add proper amount of oil.

8. Abnormal knock sound on

power end, bearing,

crosshead etc.

1. The crosshead guide is

worn out sharply.

2. The bearing is worn out.

3. The guide is loose.

4. There is water hammer on

the fluid end.

1. Adjust the clearance or

change the worn guide.

2. Change the bearing.

3. Tighten the bolts of guide.

4. Improve the suction

performance.

Note: Besides the above estimated troubles, if other abnormal phenomena are found, the