17

3

Maintenance

3.1

General

The unit is to be maintained under the following schedule:

Table 3.1

Task Description

Frequency

Visual checking

Once a year

Check for operability

Once a year

3.2

Safety Precautions

The unit shall be maintained by personnel qualified for Accident Prevention of Level II or higher.

3.3

Maintenance Procedures

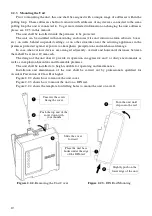

3.3.1 Visual checking of the unit includes checks for no mechanical damages, fastening reliability,

and proper condition of connecting wires and contact joints.

3.3.2 To verify the unit operates properly, please follow the instructions of Section 3.4 of this manual.

3.4

Testing Operability

Be sure that the unit configuration and wiring are consistent with this manual and the system

design documentation.

While the unit is being tested, all monitored circuits coupled with automated fire-fighting

equipment shall be disconnected from the outputs of the unit and be replaced with the simulators

similar in the load current.

After applying power to the unit, the built-in indicator READY start lighting steady until the

moment the polling loop controller polls the given address. Then the indicator goes to flash slowly.

Remove the cover from the unit and ensure that a tamper alarm message has been received by the

network controller S2000M, Orion Pro, or Sirius (a message on having restored the tamper will come

on elapsing 15 seconds after closing the unit cover).

Further checking of the unit is conducted within the system by sending the unit commands to

control its outputs.

3.5

Technical Examination

Technical examination is not applicable for this equipment.

3.6

Preservation (Depreservation, Represervation)

Preservation is not applicable for this equipment.

Warning!

Removing the unit’s PC board from its housing automatically voids the

manufacturer’s warranty