Products that make money, save money and add value to your bottom line

OIL-LEVEL CHECK (ADD OIL)

As the tool is hydraulically operated, the oil-level must

be checked at frequent intervals, preferably once a year.

Failure to maintain the oil at the proper level results in

a drop in pressure and loss of power.

CAUTION: Hydraulic oil is highly flammable. Keep

away from sparks and open flame. Do not smoke.

Hydraulic oil may cause inflammation of the eyes and

skin. If ingested, it could cause diarrhea and vomiting.

In case of eye contact, rinse in clean water for at least

15 minutes and consult a physician. In case of skin

contact, wash thoroughly with soap and water. In case

of ingestion, consult a physician immediately.

Do not induce vomiting.

1. Oil should be warm but not hot.

2. If bending arm is still moving, run the bending

arm and stop just before it reaches its full stroke

and returns.

3. Remove oil-plug and seal-washer (packing).CAU-

TION: Never remove oil-plug when unit is hot or

oil will spurt out.

4. Check that oil is level with bottom of plug hole (i.e.

that pump case if full to the brim). If oil level is

low, top up with fresh hydraulic oil with anti-foam

and anti-abrasion properties (ISO viscosity grade

VG46, e.g. Tellus46 (Shell), DTE-25 (Mobil) or

Uni-Power VG46 (Esso).

5. After topping up, extract air from system. Gently

tilt tool lengthwise and return it to a level position.

Top up again and tilt in the opposite direction.

CARE: Tool cannot function properly if oil con-

tains air bubbles.

6. Replace the oil-plug and seal-washer. Run the

bending arm until it automatically returns to the

starting position.

7. Repeat 2- 6 until the oil is fully added.

8. Check that oil-plug is tightened.

NOTE: Dispose of hydraulic oil in accordance with lo-

cal regulations. Do not pour into the sea, a river, a lake

or drains.

BOLT TIGHTNESS

Once a week, or after every 30 times use, check the

tightness of all bolts. Especially those securing housing

to the cylinder, bending roller and center roller. Using

loose rollers may result in injury to operator as well as

damage to the tool.

CARBON BRUSHES

Inspect the two carbon brushes at least once every two

months. (Nominal brush life is 200 hours).

CARE: Worn brushes will result in power loss; cause

the motor to run hot and irreparably damage the arma-

ture.

1. Disconnect tool from electrical outlet.

2. Remove Tail cover. Unscrew both brush caps and

pull out carbon brushes.

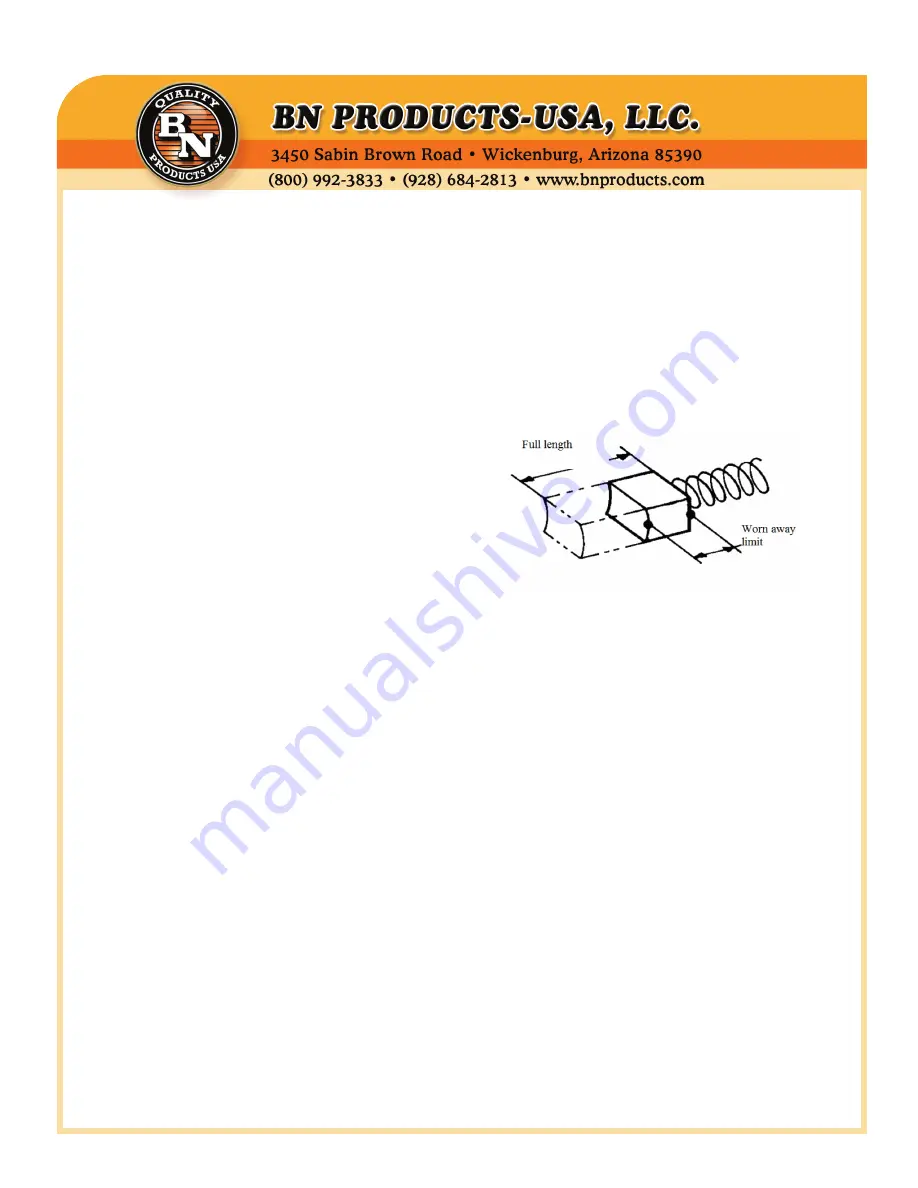

3. Replace brushes if less than 6mm in length.(We

recommend the automatic stop carbon brush

for replacement.) Pair of carbon brush : Part#.

7HTK999041 B

OVERHAUL

Return the unit to an authorized distributor for over-

haul at least once every two years, sooner if subject to

heavy use. Ignorance of proper operating procedures

can lead to accidents. If you have any other questions

about any procedures, please contact the nearest autho-

rized distributor.

*Specifications are subject to change without prior

notice.