13

ENGLISH

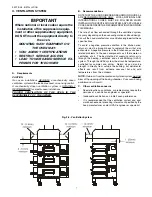

V. GAS SUPPLY

CAUTION

DURING PRESSURE TESTING NOTE THE FOLLOWING:

1. The oven and its individual shutoff valve must be discon-

nected from the gas supply piping system during any

pressure testing of that system at test pressure in excess

of 1/2 psi (3.45 kPa).

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psi (3.45

kPa).

3. If incoming pressure is over 14" W.C. (35mbar), a

separate regulator MUST be installed in the line BEFORE

the individual shutoff valve for the oven.

WARNING: To prevent damage to the control valve regu-

lator during initial turn- on of gas, it is very important to

open the manual shutoff valve very slowly.

After the initial gas turn-on, the manual shutoff valve must

remain open except during pressure testing as outlined

in the above steps or when necessary during service

maintenance.

A.

Gas Utility Rough-In Recommendations

The following gas system specifications are STRONGLY

RECOMMENDED. Deviating from these recommendations

may affect the baking performance of the oven.

Gas Meter - 650 cfh (307

l

/min) meter

Gas Line

•

DEDICATED LINE from the gas meter to the oven

•

2" (50.8mm) pipe for natural gas

•

1-1/2" (38.1mm) pipe for propane

•

Maximum length: 200' (61m). Each 90° elbow equals 7'

(2.13m) of pipe.

B.

Gas Conversion

Ovens are shipped from the factory configured for use with

natural gas. If permitted by local, national and international

codes, the oven may be converted to propane gas operation

using a Gas Conversion Kit that is supplied with the oven. Gas

orifice sizes supplied with the Kit match those shown in Tables

1-4 and 1-5 in the Description section of this Manual.

Where permitted by local and national codes, it is possible to

convert ovens from natural to propane gas, or from propane to

natural gas, after the oven has been installed. Gas Conversion

Kits are available from Blodgett for this purpose.

C.

Connection

WARNING

Some procedures in this section may require conver-

sions, readjustments, or service on the oven's gas

system. Before performing these procedures, check that the

main gas supply valve and the circuit breaker/fused discon-

nect are in the OFF ("O") position. After completing these

procedures, perform a gas leak test before operating the

oven.

CAUTION

The terms of the oven's warranty require all start-ups,

conversions and service work to be performed by a Blodgett

Authorized Service Agent. The installation, start-up and changes

required when changing from one gas type to another can be

performed ONLY by a certified professional.

NOTE:

Certain safety code requirements exist for the installation

of gas ovens; refer to the beginning of Section 2 for a list of the

installation standards. In addition:

•

In the USA, the installation must conform with local codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1.

•

In Canada, the installation must conform with local codes,

or in the absence of local codes, with the Natural Gas

Installation Code, CAN/CGA-B 149.1, or the Propane

Installation Code, CAN/CGA-B 149.2, as applicable.

•

In Australia, the installation must conform with AGA Codes

AG311 and AG601, and with any requirements of the

appropriate statutory authority.

•

In CE countries, the gas supply connection should be

according to EN-203 (gas appliance directive) and to

applicable ISO 228-1 or ISO 7-1 recommendations. All

aspects of the gas supply connection must comply with

current IEC/CEE requirements and with all applicable

local, national, and international codes.

•

For all ovens equipped with casters, the gas line connection

shall be made with:

-

A connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69

(in USA), or Connectors for Movable Gas Appliances,

CAN/CGA-6.16 (in Canada).

Check the oven’s gas supply requirements to determine the

type of gas to be used with the oven. If the gas type required does

NOT match the local supply:

•

For North American installations, a conversion kit is

supplied with the oven to allow operation using propane

gas. Refer to Part B, Gas Conversion, in this section.

•

For CE ovens, directions for converting the oven for use with

other gases are described in Part D.1, Preparation for Use

with Various Gases, in this section.

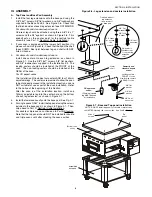

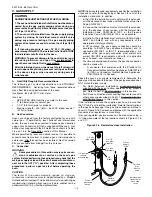

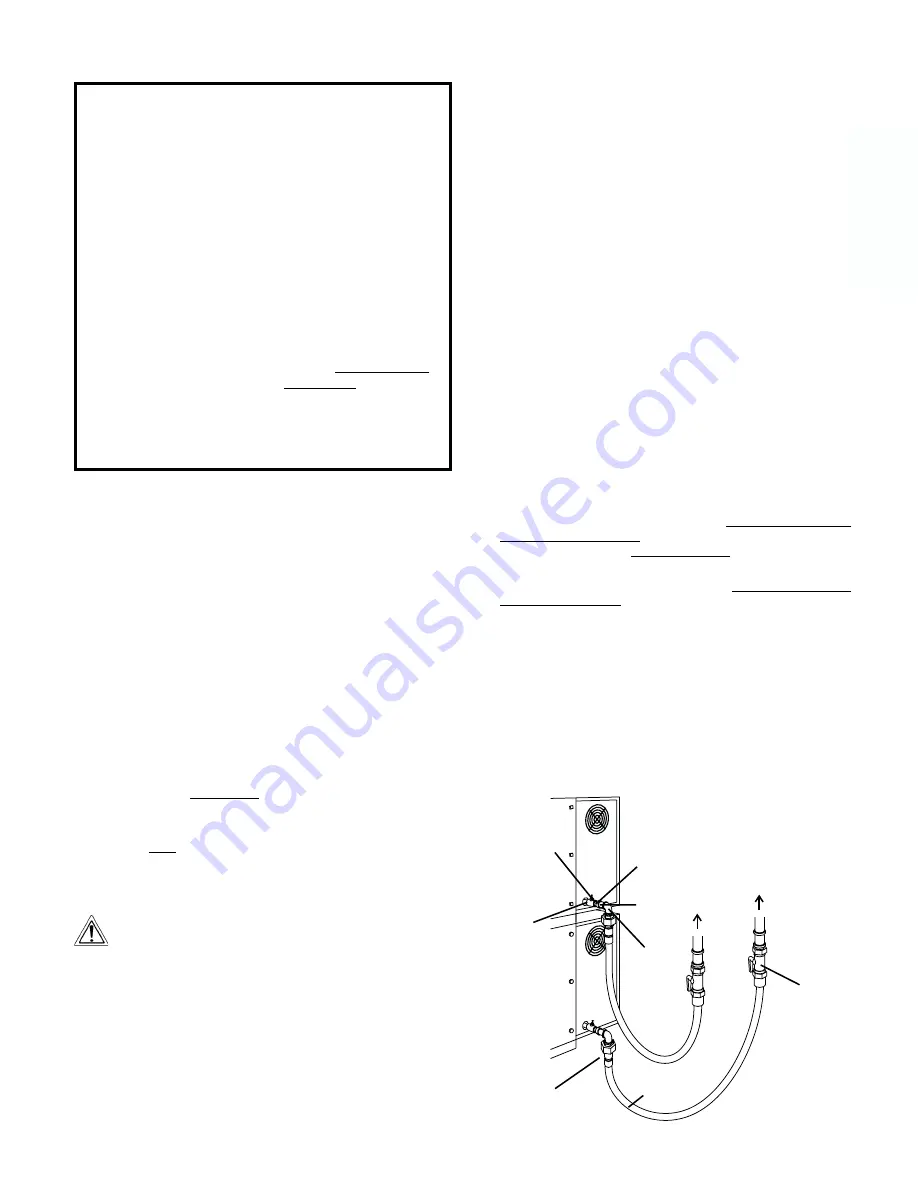

If the installation will use the supplied gas hose, be sure that

the 1/2" to 3/4" gas line fitting is attached. Refer to the instructions

in the gas hose package. One gas line connection method is

shown in Figure 2-16; however, compliance with the applicable

standards and regulations is mandatory.

Inlet and regulated gas pressures can be measured using a

“U” tube manometer at the tap locations shown in Figures 2-16

and 2-17.

SECTION 2 - INSTALLATION

Figure 2-16 - Flexible Gas Hose Installation

To Gas

Supply

Pipe

90°

Elbow

Quick-

disconnect

device

Flexible

Gas Hose

Full-Flow

Gas

Shutoff

Valve

3/4" gas

pipe nipple

3/4"-1/2"

gas pipe

reducer

Individual gas

connection for

each oven

cavity

1/2" gas

pipe nipple

1/2" gas line

tee with

pressure tap

Summary of Contents for BG2136 Double

Page 1: ......

Page 4: ...iv ...

Page 6: ...vi NOTES ...

Page 24: ...18 ENGLISH NOTES SECTION3 OPERATION ...

Page 30: ...24 ENGLISH ...

Page 32: ...26 ENGLISH page 1 FRANÇAIS page 57 ESPAÑOL página 85 DEUTSCH seite 29 ...

Page 34: ...28 ENGLISH page 1 FRANÇAIS page 57 ESPAÑOL página 85 DEUTSCH seite 29 ...

Page 36: ...30 ENGLISH page 1 FRANÇAIS page 57 ESPAÑOL página 85 DEUTSCH seite 29 ...

Page 38: ...32 ENGLISH page 1 FRANÇAIS page 57 ESPAÑOL página 85 DEUTSCH seite 29 ...

Page 40: ...34 ENGLISH page 1 FRANÇAIS page 57 ESPAÑOL página 85 DEUTSCH seite 29 ...

Page 42: ...36 ENGLISH page 1 FRANÇAIS page 57 ESPAÑOL página 85 DEUTSCH seite 29 ...

Page 44: ...38 ENGLISH page 1 FRANÇAIS page 57 ESPAÑOL página 85 DEUTSCH seite 29 NOTES ...

Page 46: ...Fig 6 2 Wiring diagram BG2136 Gas Oven 208 240V 50 60 Hz 1 Ph ...

Page 48: ...NOTES ...

Page 49: ...NOTES ...