www.blaubergventilatoren.de

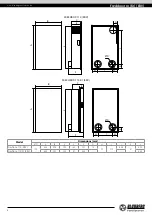

Freshbox 110 (K1) (ErV)

9

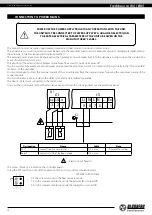

MOUNTING AND SET-UP

READ THE USER'S MANUAL BEFORE INSTALLING THE UNIT.

BEFORE INSTALLING ADDITIONAL ExTERNAL DEVICES,

READ THE RELEVANT USER MANUALS

Freshbox 110 (ERV)

The delivery set includes a mounting template for marking the

holes.

Fix the mounting template at the required level on the wall.

Mark the holes for the air ducts and holes for mounting the unit.

Before installation operations route necessary cables and wires to

the unit mounting place.

Remove the mounting template and drill two through holes

Ø 120 mm in the wall for the air ducts.

When mounting the unit with an extract spigot prepare a hole in

the wall for a connecting bend and for laying of a rectangular air

duct.

A connecting bend, rectangular and round air ducts are available

separately.

Drill Ø 8 mm holes to mount the unit.

Install the expansion anchors, remove the perforated fillers for the

air ducts from the mounting template and install the mounting

template back.

Prepare air ducts of required length. Note that the telescopic air

duct end must protrude for the distance that enables installation

of the outer ventilation hood. For details, refer to the installation

instruction for the ventilation hood.

The outer ventilation hood is available separately.

Insert the air ducts in the corresponding holes of the mounting

template. Install the air duct A with the minimum slope of 3 mm

for condensate removal.

To install the unit with an additional spigot, insert the connecting

bend into the prepared hole in the wall, aligning the mounting

template hole with a round end of the connecting bend. Connect

a rectangular duct to the connecting bend. Fill the gaps between

the air ducts and the wall with a mounting foam.

Wait till the mounting foam hardens then take off the mounting

template and remove the foam excess.

Cut off the protruding air duct parts to be flush with the wall

surface.

A

WHILE INSTALLING THE UNIT ENSURE CONVENIENT ACCESS FOR SUBSEQUENT

MAINTENANCE AND REPAIR.