11

EN

Consult local laws and ordinances before operating FPV

equipment. In some areas, FPV operation may be limited or

prohibited. You are responsible for operating this product in

a legal and responsible manner.

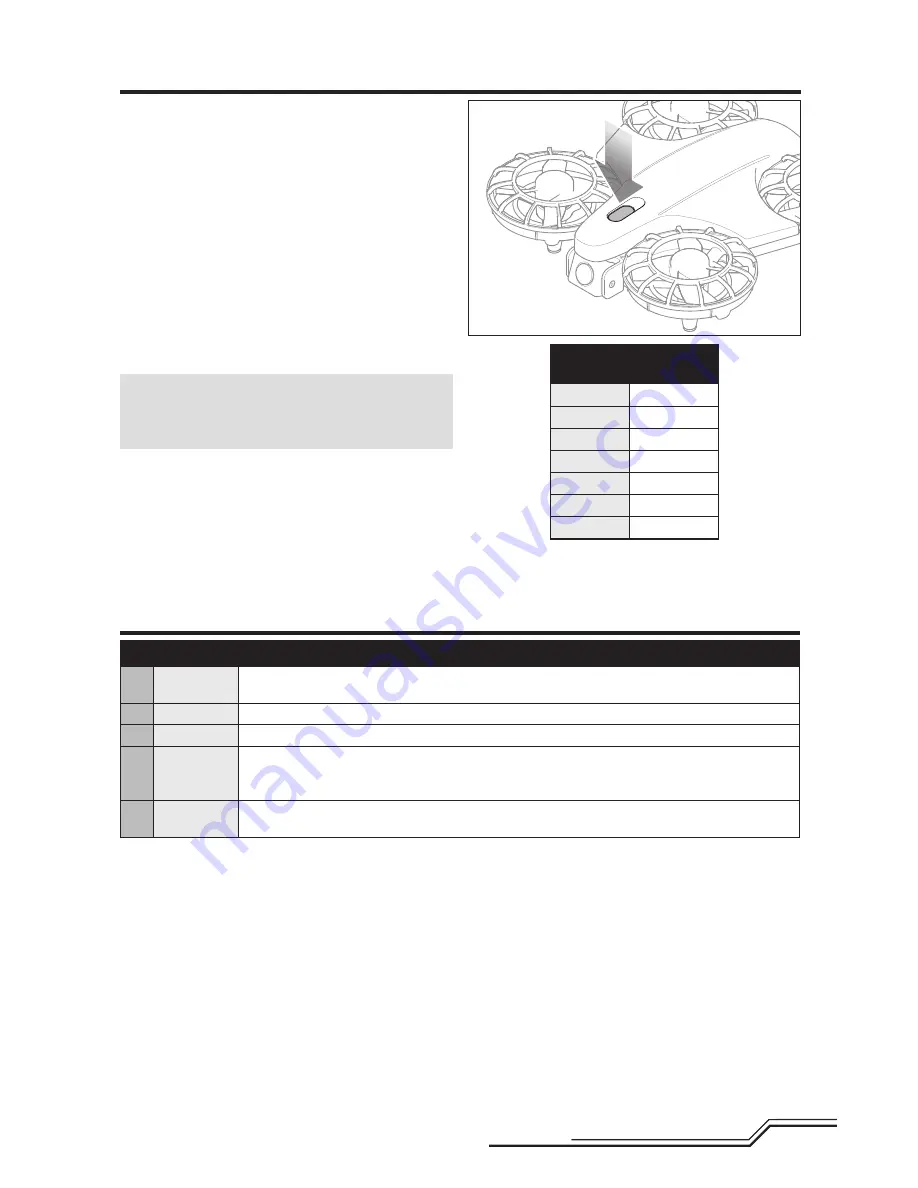

1. Power on your radio transmitter, then power on the aircraft.

2. Power on the video receiver to make sure the channel is

clear and then power on the video transmitter.

3. Select the desired video transmitter channel by pressing

the button on the quadcopter to scroll through the available

channels, 1-7, as shown.

4. Adjust the vertical camera angle by rotating the camera

up or down prior to fl ight.

5. Perform a range test before fl ying.

If you experience static in the video feed, select a different

channel.

NOTICE:

The 25mW micro video camera range on your

quadcopter is less than your fl ight control transmitter

range. Ensure you have adequate video camera range

for fi lming.

Tip:

If you are fl ying with an FPV headset and are prone

to motion sickness, sit in a chair. If you start to suffer from

motion sickness while fl ying, lower your chin against your

chest.

Fly in open areas, away from people, trees, cars, and

buildings. The range of the system can be impacted by any

obstructions blocking your signal. It is normal to see break

up in the video going behind trees and other obstacles.

Ultra Micro FPV Camera

Transmitter Channels

Channel 1

5740 MHz

Channel 2

5760 MHz

Channel 3

5780 MHz

Channel 4

5800 MHz

Channel 5

5820 MHz

Channel 6

5840 MHz

Channel 7

5860 MHz

Using the Micro FPV Camera

These frequencies are compatible with Band F, Fatshark,

Immersion RC and Airwave video receiver products

Post-Flight Inspection and Maintenance Checklist

√

Cleaning

Make sure the battery is not installed before cleaning. Remove dust and debris with a soft brush

or a dry, lint-free cloth.

Motors

Replace the motor when the model will not fl y steady or veers off when doing a climb out.

Wiring

Make sure the wiring does not block moving parts. Replace damaged wiring and loose connectors.

Fasteners

Make sure there are no loose screws, other fasteners or connectors. Do not over-tighten metal

screws in plastic parts. Tighten screws so the parts are mated together, then turn the screw only

1/8th of a turn more. Do not use threadlock on or near plastic parts.

Propellers

Make sure there is no damage to the propellers or other parts that move at high speed. Damage to

these parts includes cracks, burrs, chips or scratches. Replace damaged parts before fl ying.