NOTICE:

THIS PUMP CONTAINS SOME RESIDUAL TEST FLUID

AND RUST INHIBITOR. IF NECESSARY, FLUSH PUMP

PRIOR TO USE.

Hazardous voltage.

Can shock, burn

or cause death.

Install, ground and wire to local and

National Electrical Code requirements.

Install an all-leg disconnect switch near

the unit motor.

Disconnect and lockout electrical power

before installation or service.

Electrical supply MUST match motor nameplate

specifications.

Motors equipped with thermal protection automatically

disconnect motor electrical circuit when overload exists.

Motor can start unexpectedly and without warning.

NOTICE:

BLACKMER CO2 PUMPS MUST ONLY BE INSTALLED

IN SYSTEMS DESIGNED BY QUALIFIED ENGINEERING

PERSONNEL. SYSTEM DESIGN MUST CONFORM

WITH ALL APPLICABLE REGULATIONS AND CODES

AND PROVIDE WARNING OF ALL SYSTEM HAZARDS.

INSTALLATION AND OPERATION

CRL BASE MOUNTED MOTOR DRIVEN PUMPS

PRE-INSTALLATION CLEANING

Foreign matter entering the pump WILL cause extensive

damage. The supply tank and intake piping MUST be cleaned

and flushed prior to pump installation and operation.

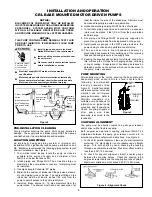

LOCATION AND PIPING

An improperly designed piping system or improper unit

installation WILL significantly reduce pump performance and

life. Blackmer recommends the following piping system layout

and unit installation. See Figure 2.

1. To minimize intake losses, locate the pump as close as

possible to the source of supply and a minimum of two

feet (0.6 m) below the tank outlet.

2. Intake piping and fittings MUST be at least as large in

diameter as the pump intake connection. Inlet piping must

be insulated.

3. Use high strength Schedule “80” piping.

4. Minimize the number of intake line fittings (valves, elbows,

etc.) and piping turns or bends. The nearest fitting on the

intake line must be at least 6 inches (152 mm) from the

pump to permit access to the pump relief valve .

5. Install an intake strainer 5 - 10 pipe diameters from the

pump intake. The strainer must have a net open area of at

least four times the area of the intake pipe. Strainers must

be cleaned regularly to avoid pump starvation.

6. Intake and discharge piping MUST be free of all leaks.

7. To facilitate piping expansion and contraction, expansion

joints must be placed 3 feet (0.9 m) from the pump intake

and discharge.

8. ALL piping and fittings MUST be properly supported to

prevent any piping loads from being placed on the pump.

9. Install pressure gauges in the NPT ports provided in the

pump casing to check pump performance at start up.

10. The use a vapor return line will speed up delivery by

preventing back pressure from building up at the receiving

tank and reducing pressure in the supply tank.

11. Keeping the liquefied gas systems full of liquid, even when

idle, will keep the O-rings from changing shape, shrinking

or super cooling. Evaporation of liquefied gas leaves an

abrasive powder on the surface which can cause wear to

the pump, meter, and seals.

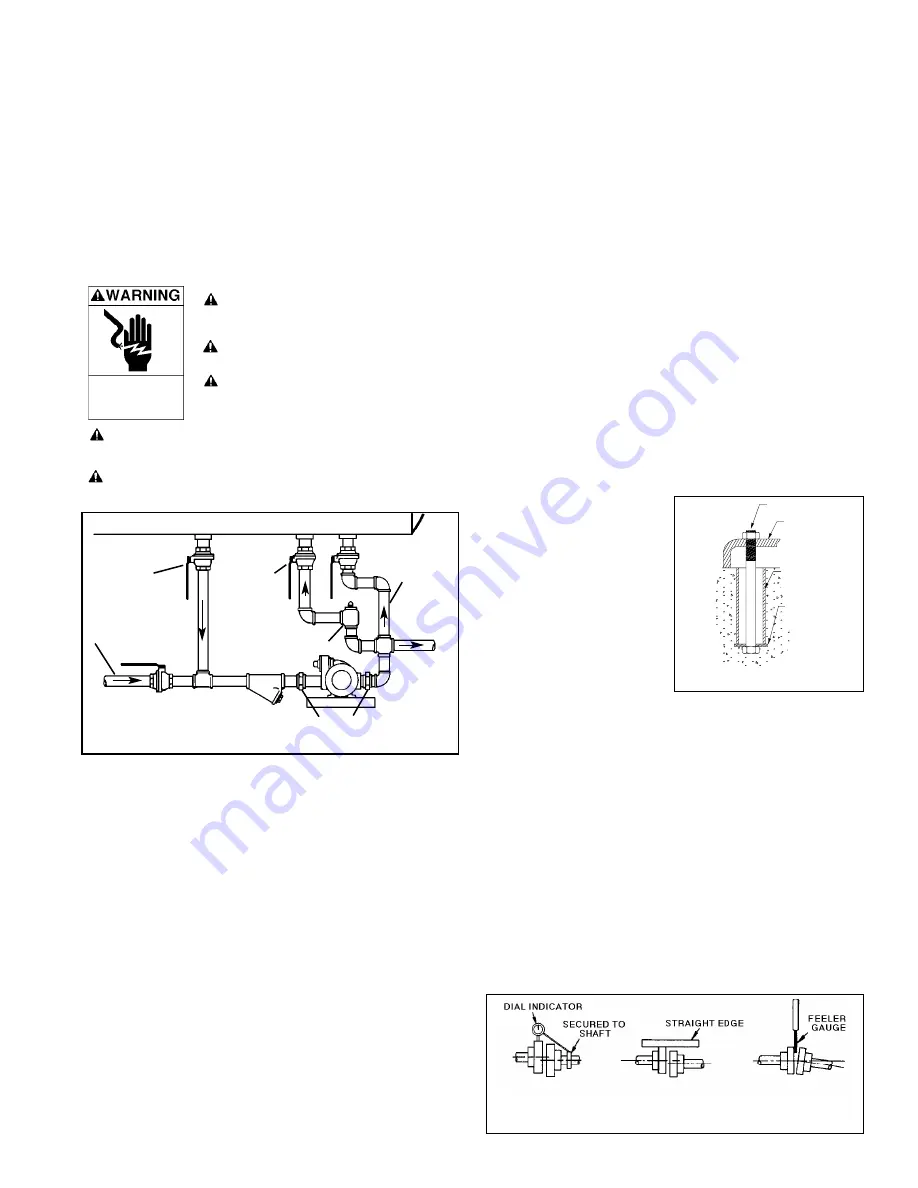

PUMP MOUNTING

Permanently mount the unit by securing the base plate with

adequately sized anchor bolts to a level concrete floor

following recommended

industry standards (See

Figure 3). A solid foundation

will reduce system noise and

vibration, and will improve

pump performance. Refer to

ANSI/HI standards or a

suitable pump handbook for

information on typical pump

mounting and foundations.

Check coupling alignment

after pump and base

assembly is secured to the

foundation.

BOLT

BASE

STANDARD

PIPE

WASHER

Figure 3

BOLT

BASE

STANDARD

PIPE

WASHER

COUPLING ALIGNMENT

The pump must be directly coupled to a gear, gear reducer,

and/or driver with a flexible coupling.

Both angular and parallel coupling alignment MUST be

maintained between the pump, gear reducer, motor, etc. in

accordance with manufacturer’s instructions. See Figure 4.

1. To check for parallel alignment, the use of a dial indicator is

preferred. If a dial indicator is not available use a straight

edge. Turn both shafts by hand, checking the reading

through one complete revolution. Maximum offset must be

less than .005" (125 microns).

2. To check for angular alignment, insert a feeler gauge

between the coupling halves. Check the spacing in 90

degree increments around the coupling (four check points).

Maximum variation must not exceed .005" (125 microns).

Figure 4 - Alignment Check

3

Storage Tank

Figure 2

Unions

Bypass Valve

Gate or Ball

Valves

Intake Connection

for unloading tank

cars or tank trucks

Do no start

pump unless

this valve is

open.

Alternate

Discharge

to Storage

Tank

Discharge

Strainer