SAFETY DATA

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

Hazardous voltage.

Can shock, burn

or cause death.

Hazardous

machinery can

cause serious

personal injury.

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING MAINTENANCE

CAN CAUSE SERIOUS PERSONAL

INJURY OR DEATH.

Hazardous or toxic

fluids can cause

serious injury.

IF PUMPING HAZARDOUS FLUIDS

SYSTEM MUST BE FLUSHED PRIOR

TO PERFORMING SERVICE.

DO NOT ATTEMPT TO OPEN THE PUMP

UNTIL YOU HAVE BLED OFF THE

PRESSURE. ON SYSTEMS WITH

METERS, THE DIFFERENTIAL VALVE

WILL KEEP LIQUID UNDER PRESSURE

IN THE PUMP, METER AND PIPING

EVEN WHEN THE HOSE IS EMPTIED.

Hazardous pressure

can cause personal

injury or property

damage.

PUMP DATA

Model Designations:

Motor Drive & Truck Mount

CRL4A

Discontinued

TCRL4, TCRLF4A

Torque Required @ 100 psi

205 lbs ft

(6.9 bar)

(278 Nm)

Maximum Temperature

240

o

F (115

o

C)

Minimum Temperature

- 30

o

F (- 34

o

C)

Maximum Pump Speed

640 RPM

Maximum Differential Pressure

100 psi ( 6.9 bar)

Maximum Working Pressure

525 psi ( 36.2 bar)

(Inlet Pr Differential Pressure)

INITIAL START UP INFORMATION

TECHNICAL DATA

PUMP WITH WELDED CONNECTIONS

NOTICE:

FOR PIPING CONNECTIONS REQUIRING WELDING THE

PUMP’S NON-METALLIC O-RINGS MUST BE REMOVED

PRIOR TO WELDING. FAILURE TO DO SO WILL

DAMAGE THE O-RINGS.

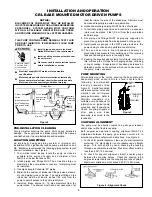

Before welding the piping, remove the O-rings from under

the inlet flange, outlet flange and relief valve cover as

indicated in Figure 1.

Reinstall the inlet and outlet flanges. Weld the piping to the

the inlet and outlet flanges. After the welding is complete,

reinstall the O-rings.

Figure 1

2

FAILURE TO SET THE VEHICLE

EMERGENCY BRAKE AND CHOCK

WHEELS BEFORE PERFORMING

SERVICE CAN CAUSE SEVERE

PERSONAL INJURY OR PROPERTY

DAMAGE.

Hazardous machinery

can cause severe

personal injury or

property damage.

FAILURE TO RELIEVE SYSTEM

PRESSURE PRIOR TO PERFORMING

PUMP SERVICE OR MAINTENANCE

CAN CAUSE PERSONAL INJURY OR

PROPERTY DAMAGE.

Hazardous pressure

can cause personal

injury or property

damage.

O-RING

O-RING

O-RING

O-RING

O-RING

O-RING

Model No. ________________________________

Serial No. ________________________________

I.D. No. __________________________________

Date of Installation: ________________________

Discharge Gauge Reading: __________________

Inlet Gauge Reading: _______________________

Flow Rate: ________________________________