201A-A00 Page 5/12

OPERATION

DIRECT ACTING RELIEF VALVE

NOTICE:

The direct acting relief valve is designed to protect the

pump from excessive pressure and must not be used as

a system pressure control valve.

Pumping volatile liquids under suction lift may cause

cavitation.

DO NOT

partially close the discharge valve. This

WILL

result in internal relief valve chatter. For these

applications, install an external bypass valve, and any

necessary piping, back to the storage tank. Use a bypass

system when operating for extended periods (more than 1

minute) against a closed discharge valve.

RELIEF VALVE SETTING AND ADJUSTMENT

Hazardous machinery

can cause serious

personal injury or

death.

Failure to disengage PTO before

adjusting pump relief valve can cause

severe personal injury or death.

Hazardous pressure

can cause serious

personal injury or

property damage.

Incorrect settings of the pressure relief

valve can cause pump component

failure, personal injury, and property

damage.

Hazardous or toxic

fluids can cause

serious injury.

Relief valve cap is exposed to pumpage

and will contain some fluid

The relief valve pressure setting is marked on a metal tag

attached to the valve cover. Generally, the relief valve should

be set at least 15 -20 psi (1.0 - 1.4 Bar) higher than the

operating pressure, or the external bypass valve setting

(if equipped).

DO NOT remove the R /V Cap OR adjust the relief valve

pressure setting while the pump is in operation.

1.

To INCREASE the pressure setting,

remove the relief

valve cap, loosen the locknut, and turn the adjusting screw

inwar

d, or clockwise. Replace the valve cap.

2.

To DECREASE the pressure settin

g, remove the relief

valve cap, loosen the locknut, and turn the adjusting screw

outwar

d, or counterclockwise. Replace the valve cap.

Refer to the individual Blackmer pump parts lists for various

spring pressure ranges. Unless specified otherwise, pumps

are supplied from the factory with the relief valve adjusted to

the mid-point of the spring range.

OPTIONAL PNEUMATIC RELIEF VALVE

The optional pneumatic actuated relief valve is designed to

operate at two different relief pressures. The

High Pressure

mode provides pressure for product delivery. The Low

Pressure mode allows the pump to bypass fluid at lower

pressure during no flow conditions. Flow sense products are

available from other manufacturers. When air pressure is

applied, the pneumatic valve achieves the maximum pressure

setting to allow the full liquid flow through the system.

The pneumatic relief valve can be supplied with either a low

pressure or a high pressure spring:

The

low pressure spring

(8A) will bypass at 75 psi (5.2

bar) in actuated mode, and 40 psi (2.8 bar) full flow in

non-actuated mode. The low pressure spring requires

60 psi (4.1 bar) minimum air pressure to activate.

The

high pressure spring

(8B) will bypass at 115 psi

(7.9 bar) in actuated mode, and 55 psi (3.8 bar) full flow

in non-actuated mode. The high pressure spring

requires a minimum of 95 psi (6.6 bar) air pressure to

activate.

The pneumatic relief valve is controlled by a three-way valve

piped to vent the pneumatic valve to atmosphere when in the

OFF position. The breather (10B) in the cover is designed to

function as a “tell-tale” to indicate any seal problems with the

actuating piston.

NOTICE:

If any fluid or air flow appears at the breather (10B), the

seals (9D or 9F) are leaking and MUST be REPLACED

immediately.

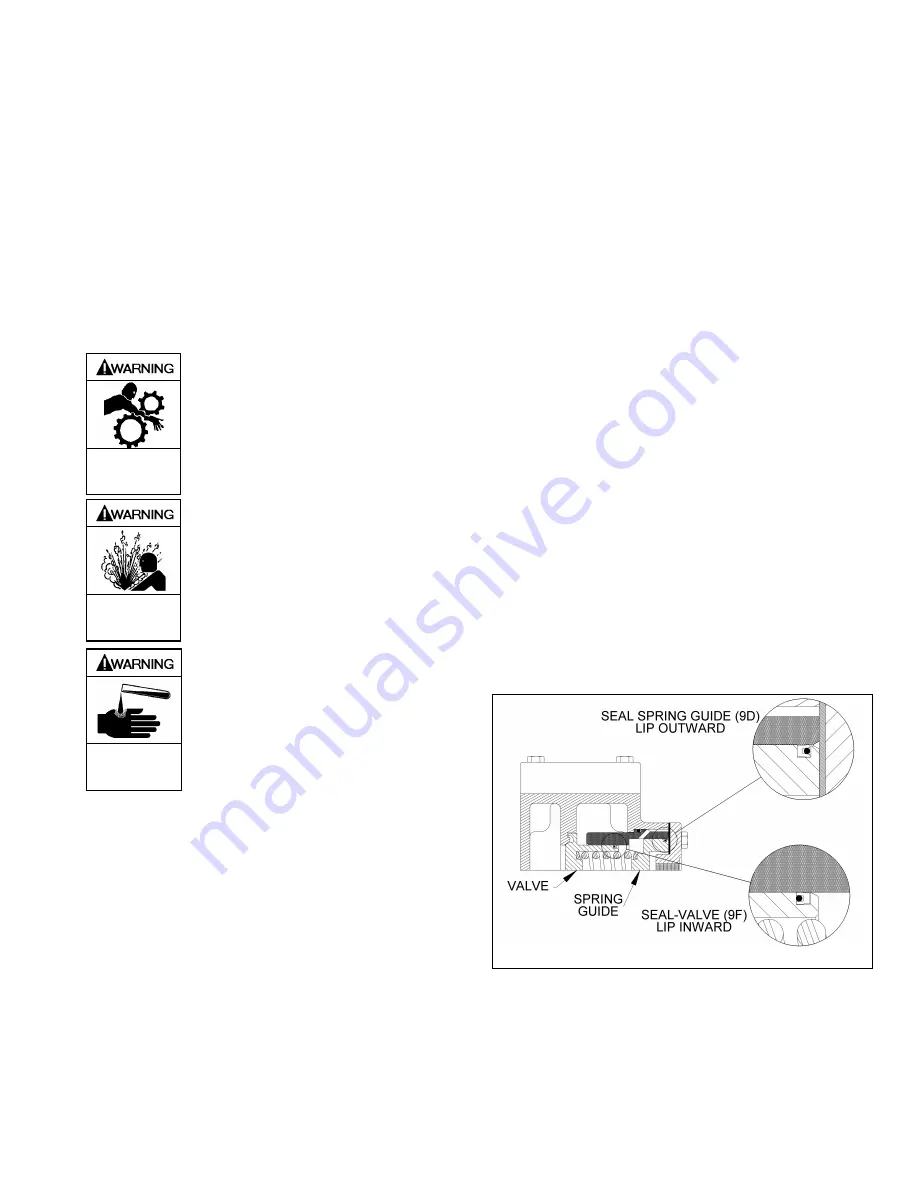

When replacing the pneumatic relief valve seals (9D and 9F),

it is important that they be positioned properly, as shown in

Figure 2.

Figure 2 – Optional Pneumatic Relief Valve

Summary of Contents for ATX300A

Page 11: ...201A A00 Page 11 12 NOTES...