18

VACUUM HOLD TEST

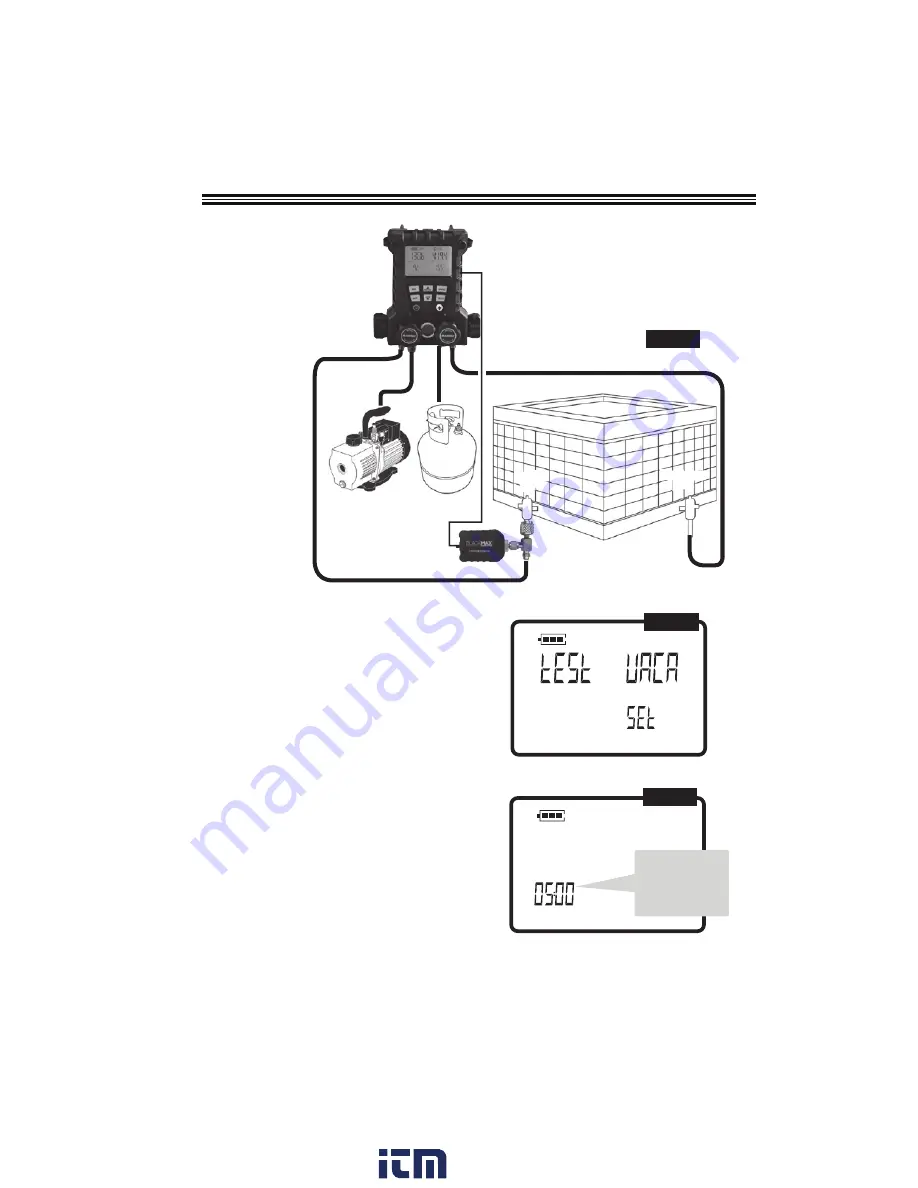

FIG.11

4. In this mode, the manifold will show current vacuum

in the system. The display begins to show vacuum

levels at 25000 microns or less and is accurate to

+/- 10 microns. Continue to run vacuum pump until

the desired vacuum level is reached. Once reached,

proceed to Vacuum Hold Test.

5.

Vacuum Hold Test

- To perform this test, press

[CLR]

to go to the

Main Screen

[

FIG.1

] Vacuum

Gauge Accessory should still be plugged into

manifold.

6. At

Main Screen

[

FIG.1

] press

[TEST]

. The

Test

Vacuum Set Screen

appears [

FIG.12

]

7. Press

[SET]

to advance to Vacuum Hold Test –

Time Set Screen [

FIG.13

].

8. Use

[UP/DOWN ARROWS]

to adjust test

duration in 5 minutes increments (minimum

time is pre-programmed at 5 minutes).

A) Press

[SET]

to store Vacuum Test duration

time.

Vacuum Hold Test Screen

[

FIG.14

]

will now be displayed.

APO

Vac

FIG.12

Test Vacuum Set Screen

hh : mm

Vac

APO

Vacuum Hold Test Time Set Screen

FIG.13

Set test

duration (adjust

in 5 minute

increments

NOTE: The Vacuum Reading in the upper Left display is still active. The Reading in the

upper Right display is not active unit steps 2 and 3 are completed.

3. Assemble the BLACKMAX

MDXVG vacuum gauge

accessory to the Suction

Port on an AC system as

shown [

FIG.11

].

Suction

port

Discharge

port

Suction

port

Discharge

port

AVT45 Brass

Tee Connector

Vacuum Gauge

Accessory

www.

.com

1.800.561.8187