CT-110-2

6

* For the HS.53 and CSHP compressors, the SE-i1 is

exclusively delivered as a separate basic sensor kit

(part number 347 050 02). It must be installed, wired

and connected in the system's switch cabinet!

Use of the SE-i1 in combination with refrigerants of the

A3 (e.g. propane) and A2 safety groups presents a

DANGER

risk of explosion!

The provided protection device contains ignition

sources capable of igniting propane and refri-

gerants of the A3 and A2 safety groups. Install

the protection device outside the hazardous

zone, for example in a tight switch cabinet.

➀ Completion sensor kit

HS.64 .. HS.85, CS.65 .. CS.95:

If the SE-i1 was ordered ex factory with a basic sensor

kit, it can be retrofitted with the completion sensor kit.

Afterwards, all protective and monitoring functions of

the device can be activated and fully used. For this, all

components of the completion sensor kit must be

mounted on the compressor, wired and configured us-

ing the BEST SOFTWARE (see chapter Mounting and

activation of the completion sensor kit, page 8).

When ordering the full sensor kit for the compressors

HS.64 .. HS.85 And CS.65 .. CS.95, all components of

the completion sensor kit are already installed and

electrically connected to the compressor. The comple-

tion sensor kit is not available for CSHP compressors.

The completion sensor kit (HS.64 .. HS.85 And CS.65 ..

CS.95, part number 347 050 03) consists of the follow-

ing components:

• Low pressure and high pressure transmitters with

connecting cables.

• T-pieces for connecting the pressure transmitters to

the high pressure and low pressure connection of

the compressor.

• Discharge gas temperature and oil temperature

sensor (NTC) incl. connecting cable.

• All cable bushings M25x1.5, M20x1.5, M16x1.5 with

hexagon nuts for the terminal box of the compressor.

Mounting and electrical connection, see chapter Mount-

ing and activation of the completion sensor kit, page

8 and see chapter Electrical connection, page 14.

② Optional temperature sensor

For example, for measurements of the suction gas, li-

quid or ambient temperature. Is considered during the

data log.

• Temperature sensor with screw-in thread (part num-

ber 347 041 01) + cable with plug (part number

347 033 01).

– 1/8-27 NPTF thread

– Measuring range: -40°C .. +125°C

• Temperature sensor to be placed on the pipe sur-

face (part number 347 033 01).

– for measurements of the suction gas temperature

on the pipe surface or measurements of the ambi-

ent temperature.

– Measuring range: -30°C .. +105°C

– Enclosure class: IP65

– Cable length: 5 m

③ Unused oil monitoring inputs

With the setting "SE-C1 Replacement" or "SE-C2 Re-

placement", unused oil monitoring inputs must be deac-

tivated by means of bridges. They must be set between

the following terminals.

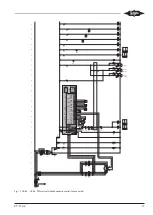

Fig. 1: Bridge to deactivate the oil monitoring inputs

Summary of Contents for SE-i1

Page 54: ...Notes...

Page 55: ...Notes...