CT-110-2

14

6

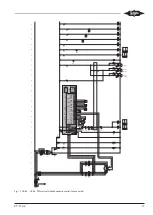

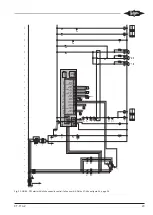

Electrical connection

Electrically connect SE-i1 in accordance with the

schematic wiring diagrams. Observe the safety stand-

ards EN 60204, EN 60364 and national safety regula-

tions.

WARNING

Risk of electric shock!

Before performing any work in the terminal box

of the compressor: Switch off the main switch

and secure it against being switched on again!

Close the terminal box of the compressor before

switching on again!

!

!

NOTICE

Potential failure of the protection device and the

motor due to improper connection and/or faulty

operation!

Connect properly according to the schematic

wiring diagrams and check the connections for

tight seat.

The cables and terminals of the PTC control cir-

cuit must not come into contact with the control

voltage or operating voltage!

6.1

Schematic wiring diagrams for CS.65 .. CS.95

compressors:

Abbr. Component

B2

Control unit (cooling demand) or command for

compressor start (release signal from the sys-

tem controller) or controller On/Off

B6

High pressure transmitter

B7

Low pressure transmitter

F1

Main fuse

F2

Compressor fuse

F3

Control circuit fuse

F4

Oil heater fuse

F5

High-pressure switch

F6

Low pressure switch

F7

Switching on delay "ECO"

F8

Oil level switch (minimum oil level), option

F9

Control thermostat "LI"

F10

Control thermostat for additional oil injection

F13

Thermal overload relay "motor" (1st part wind-

ing and star-delta)

F14

Thermal overload relay "motor" PW2

F17

Control transformer fuse

F21

Fuse of the heating element in the terminal

box

Abbr. Component

H1

Signal lamp "fault SE-i1"

H2

Signal lamp “pause time”

K1

Contactor "1st part winding" (PW) or main

contactor (star-delta)

K2

Contactor "2nd part winding" (PW) or delta

contactor (star-delta)

K3

Star contactor (star-delta)

K2T

Time relay “pause time” 300 s

K3T

Time relay "part winding" 0.5 s or "star-delta"

1 s (CS.95: 1.5 .. 2 s)

K5T

Time interval relay "CR4" flashing function

on / off 10 s

M1

Compressor

Q1

Main switch

R1

Oil heater

R2

Oil temperature sensor (CS.: PTC ② or NTC

➂)

R3-8

PTC sensor in motor (CS.)

R9

Heating element for terminal box

R10

Optional temperature sensor

S1

Control switch (on/off)

S2

Fault reset "SE-i1"

T1

Control transformer (example for 230 V, re-

quired according to EN60204-1)

U

Interference suppressor: varistor or RC ele-

ment integrated into the solenoid valve plug if

required

Y1

Solenoid valve "capacity regulator” ➀

Y2

Solenoid valve "capacity regulator” ➀

Y3

Solenoid valve "capacity regulator" ➀

Y4

Solenoid valve "capacity regulator” ➀

Y5

Solenoid valve "liquid line"

Y6

Solenoid valve "ECO"

Y7

Solenoid valve "LI"

Y8

Solenoid valve "additional oil injection"

Y9

Solenoid valve “oil cooler line”

Tab. 4: Legend schematic wiring diagrams for CS.65 .. CS.95 com-

pressors

➀ Pulsing time approx. 0.5 s .. max. 1 s, depending on

the system characteristics.

② Included in the basic sensor kit.

➂ Included in the full sensor kit or completion sensor

kit.

Summary of Contents for SE-i1

Page 54: ...Notes...

Page 55: ...Notes...