53

Appendix B How to determine where to

set your alarms

1. Oxygen alarms

Two oxygen alarm set points have been provided; one for

low concentrations associated with oxygen deficiencies,

and one for high concentrations associated with oxygen

enrichment.

Oxygen deficiency is the leading cause of worker fatality

during confined space entry. All confined spaces must be

tested for oxygen deficiency before entry. Normal fresh

air contains 20.9 percent O2. Any environment in which

the oxygen concentration is less than 19.5 percent has

been determined by OSHA to be oxygen deficient. The

normal PhD Ultra low-alarm setting for oxygen deficiency

is 19.5 percent.

Common causes of this hazard are bacterial action,

displacement of oxygen by other gases, oxidation

(rusting), consumption (burning), or absorption by

materials such as wet activated carbon.

The PhD Ultra will also alarm for an excess of oxygen.

Too much oxygen in an environment can result in an

increased flammability hazard. The new OSHA

standard for confined space entry (29 CFR 1910.146)

requires that oxygen concentrations not exceed 23.5

percent. The normal setting for the high oxygen alarm is

23.5 percent.

2. Combustible gas alarms

As an environment becomes contaminated with

combustible gases or vapors, concentrations can climb

until they eventually reach ignitable or explosive levels.

The minimum amount of a combustible gas or vapor in

air which will explosively burn if a source of ignition is

present is the Lower Explosive Limit (LEL) concentration.

PhD Ultra combustible gas readings are given in percent

LEL, with a range of zero to one-hundred percent

explosive. The PhD Ultra combustible gas sensor is non-

specific and responds to all combustible gases and

vapors.

Combustible sensors contain two coils of fine wire coated

with a ceramic material to form beads. These two beads

are strung onto the opposite arms of a balanced

Wheatstone Bridge circuit. The "active" bead is

additionally coated with a palladium based material that

allows catalyzed combustion to occur on the surface of

the bead. The palladium catalyst is not consumed in the

combustion reaction, it simply enables it to occur. It is

not necessary for the combustible vapor to be present in

LEL concentrations in order for this reaction to occur.

Even trace amounts of combustible gas present in the air

surrounding the sensor will be catalytically burned on the

surface of the bead.

The "reference" bead lacks the palladium outer coating

but in other respects exactly resembles the active bead.

A voltage is applied across the active and reference

elements, causing them to heat. If combustible vapors

are present, the active bead will be heated by the reaction

to a higher temperature. The temperature of the

untreated reference bead is unaffected by the presence of

gas. The difference between the temperatures of the two

beads will be proportional to the amount of combustible

gas present.

Since the two beads are strung on the opposite arms of a

Wheatstone Bridge electrical circuit, the difference in

temperature between the beads is perceived by the

instrument as a change in electrical resistance.

It is important to note that catalytic "hot bead" type

combustible sensors require the presence of oxygen (at

least 8 - 10 percent by volume) in order to detect

accurately. A combustible sensor in a 100 percent pure

combustible gas or vapor environment will produce a

reading of zero percent LEL.

The amount of heat produced by the combustion of a

particular gas on the active bead will reflect the "Heat of

Combustion" for that gas. Heats of combustion may vary

from one combustible gas to another. For this reason

readings may vary between equivalent concentrations of

different combustible gases.

A combustible gas and vapor reading instrument may be

calibrated to any number of different gases or vapors. If

an instrument is only going to be used for a single type of

gas over and over again, it is usually best to calibrate the

instrument to that particular hazard. If the instrument is

calibrated to a particular gas it will be accurate for that

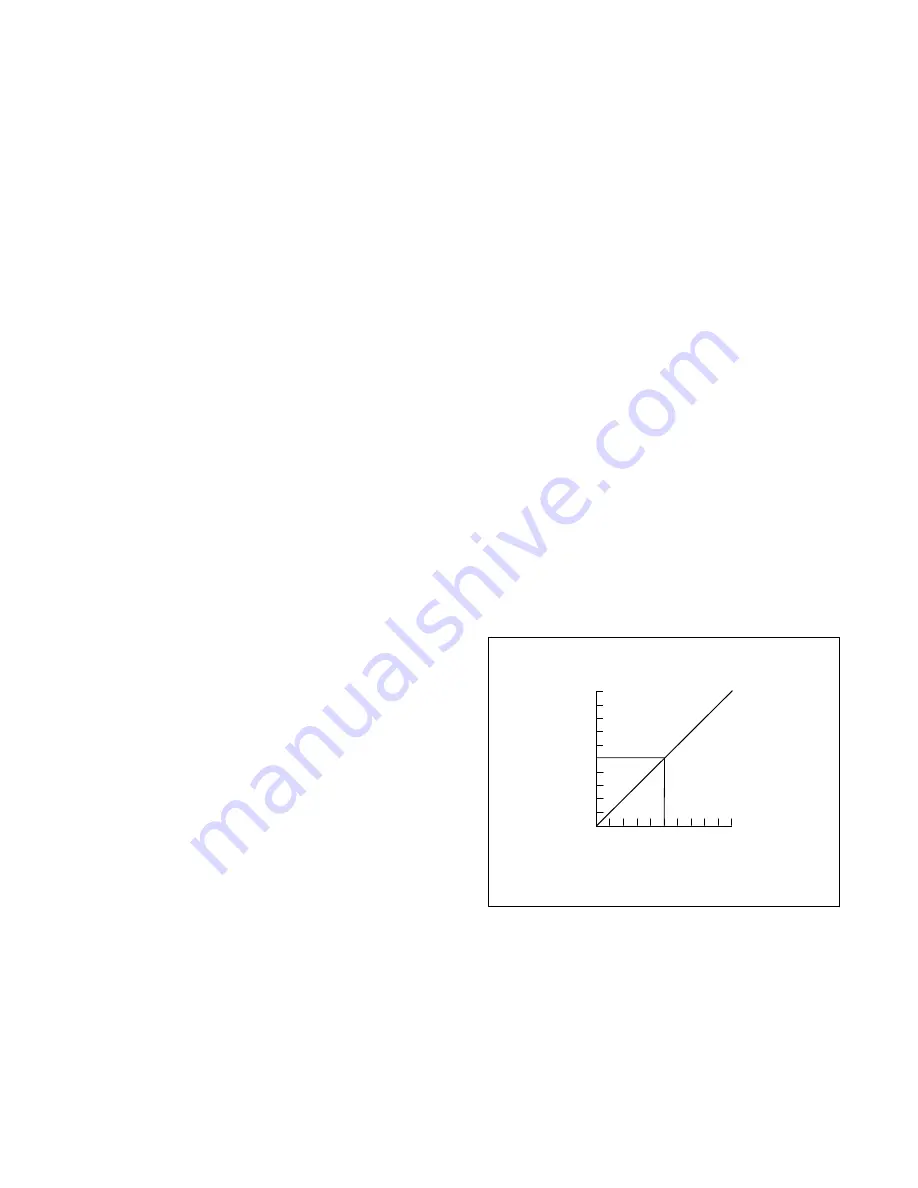

gas. This is what is illustrated in

Figure 2.1.

100

80

60

40

20

20

40

60

80

100

CALIBRATION

STANDARD

ACTUAL LEL CONCENTRATION

RELATIVE

LEL METER

RESPONSE

Figure 2.1. Combustible sensor response to the gas

used to calibrate the sensor

Note that in a properly calibrated instrument, a

concentration of 50 percent LEL produces a meter

response (reading) of 50 percent LEL.

The

Figure 2.2

illustrates what may be seen when a

combustible reading instrument is used to monitor gases

other than the one to which it was calibrated. The chart